High-frequency micro-strip antenna with substrate made of high resistance silicon

A technology of microstrip antenna and high-resistance silicon, which is applied in the direction of antenna, antenna array, antenna grounding device, etc., can solve the problems of poor flatness of the top surface of the air slot, inability to realize large-scale production, low etching rate and productivity, etc. Achieve the effects of advanced device structure design, improved flatness, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

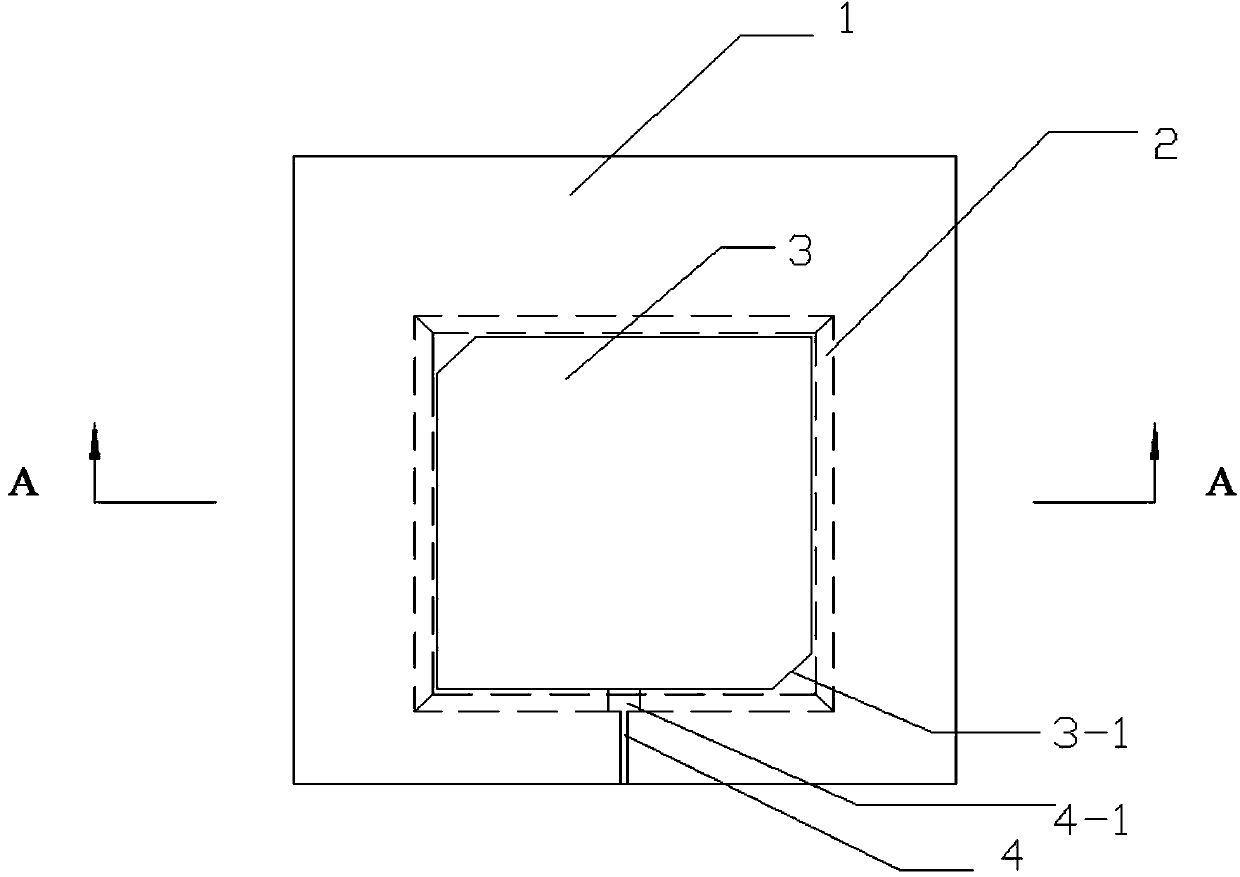

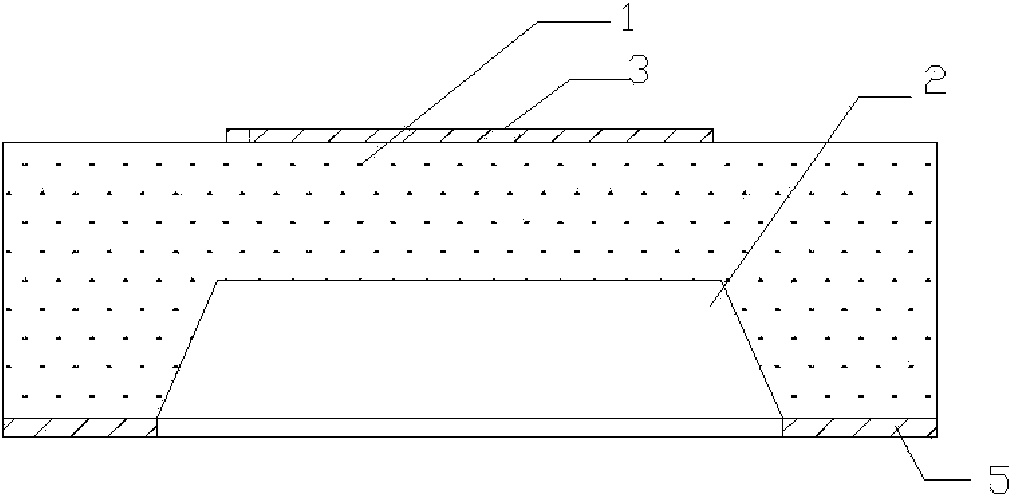

[0017] In this embodiment, the single-patch microstrip antenna is taken as an example: the relative permittivity of the high-resistance silicon substrate 1 is 11.9, the resistivity is 20000Ω·cm, the loss tangent is 0.005, the crystal orientation is [111], and the volume (length×width×thickness ) 11.2mm×11.2mm×300μm, the conical angle of the truncated pyramid groove 2 is 45°, the upper surface of the groove (length×width) 6.426×6.426mm, the lower mouth (length×width) 6.726×6.726mm , the depth of the groove is 150 μm; the radiation patch 3 (length×width) is 6.20×6.20mm, and the length of the degenerate separation unit 3-1 on it is 0.9899mm (the length is cut from the lower right corner and the upper left corner of the radiation patch 3 respectively. Take the isosceles triangle whose length is 0.7mm on both sides), feeder impedance 50Ω, feeder: 4 (length × width) 2.5 × 0.072mm, 4-1 (length × width) 0.290 × 0.280mm; grounding piece 5 (length x width) 11.2 x 11.2mm, a square hole (...

Embodiment 2

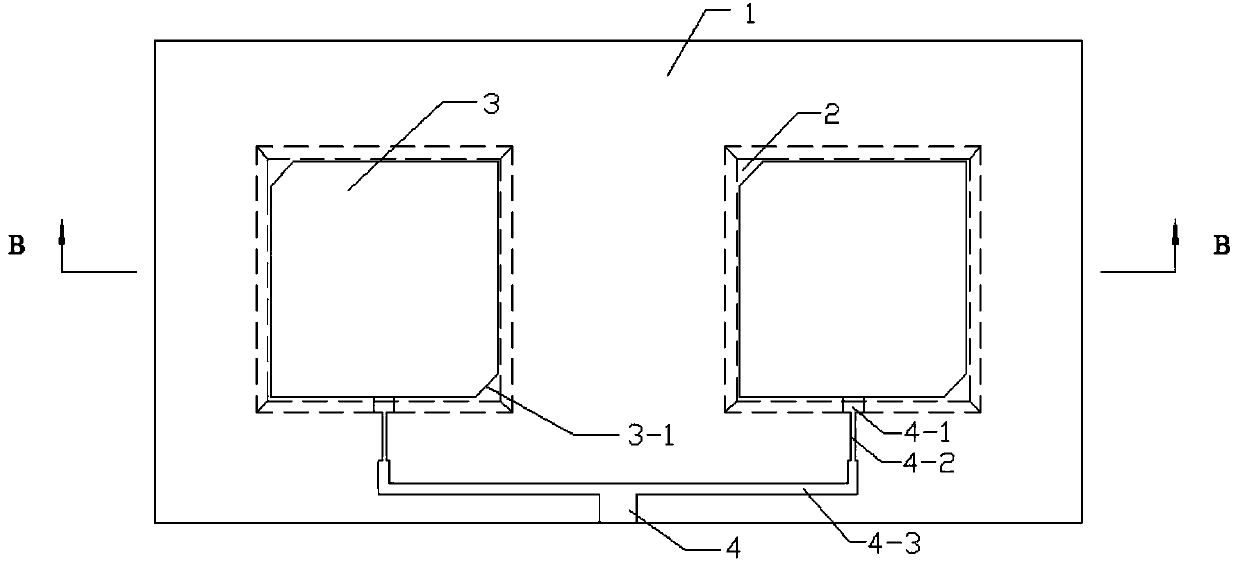

[0020] The present invention takes a binary antenna device with a working frequency of 12 GHz as an example: the high-resistance silicon substrate 1 adopts high-resistance silicon with a resistivity of 20,000 Ω cm, a relative permittivity of 11.9, a loss tangent of 0.005, and a crystal orientation of [100]. , the base (length × width × thickness) 21.0mm × 15.4mm × 500μm, the bottom of the regular quadrangular pyramid truncated groove 2 symmetrically set two upper bottom surfaces (length × width) 6.426 × 6.426mm, the lower bottom mouth (length × width) 6.780×6.780mm, truncated square groove with a groove depth of 250μm; each radiation patch 3 (length×width) 6.20×6.20mm, and the length of each degenerate unit 3-1 on it is 0.9899mm (the length is between two The lower right corner and the upper left corner of the radiation patch 3 are obtained by cutting off an isosceles triangle whose sides are both 0.7mm in length); the impedance of the connecting section between the feeder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com