Lithium isotope separation method and single-stage separation factor measurement method thereof

A lithium isotope and separation method technology, which is applied in the field of lithium isotope separation method and its single-stage separation coefficient determination, can solve problems such as human and environmental hazards, and achieve the effects of avoiding pollution, complete separation, and simple separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

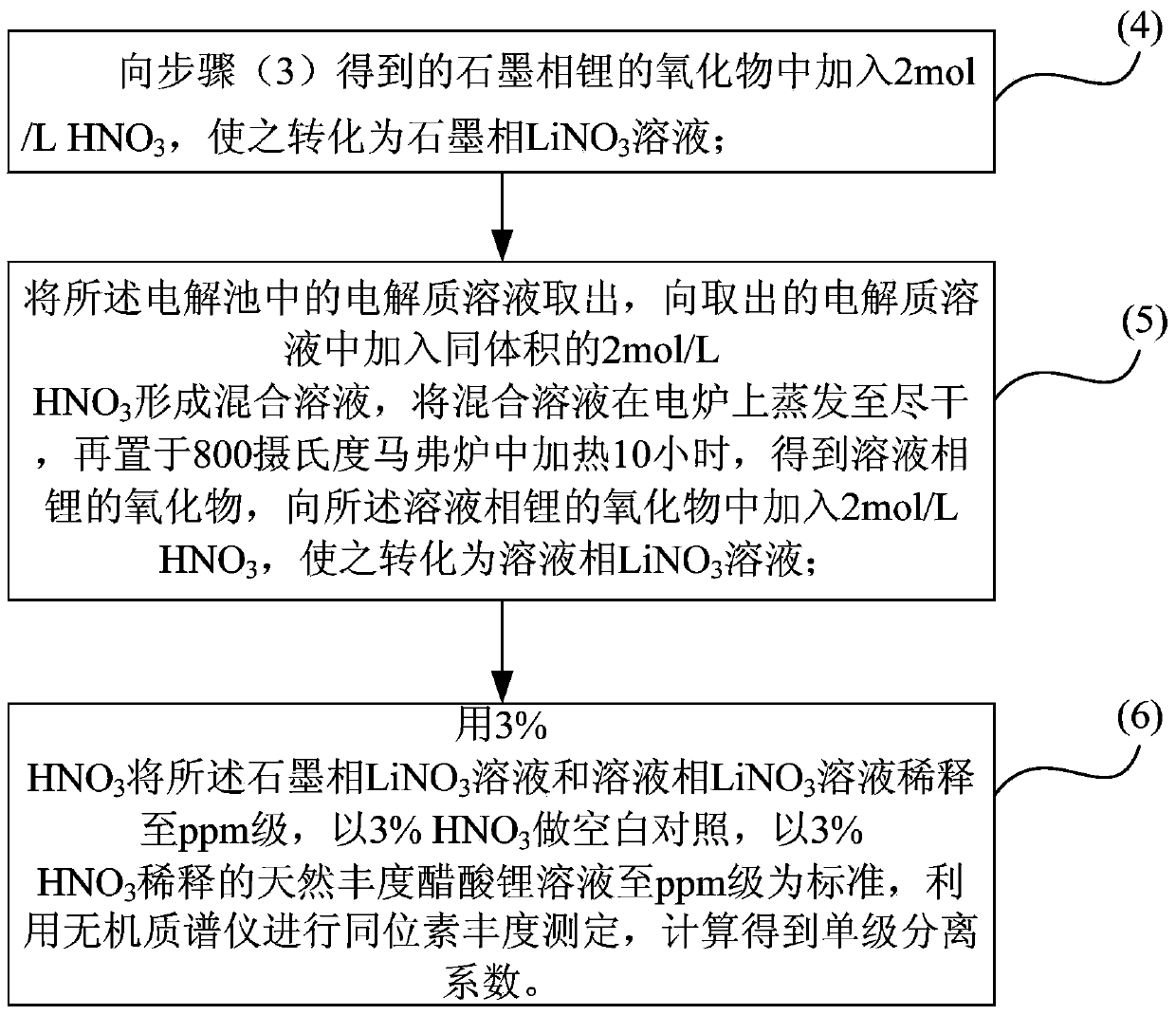

[0034]A three-electrode electrolysis system is adopted, and a working electrode, an auxiliary electrode and a reference electrode are arranged in the electrolytic cell, wherein the working electrode is a graphite sheet, and the electrolyte solution is a lithium acetate-dimethylsulfoxide solution of 0.075mol / L, comprising the following steps:

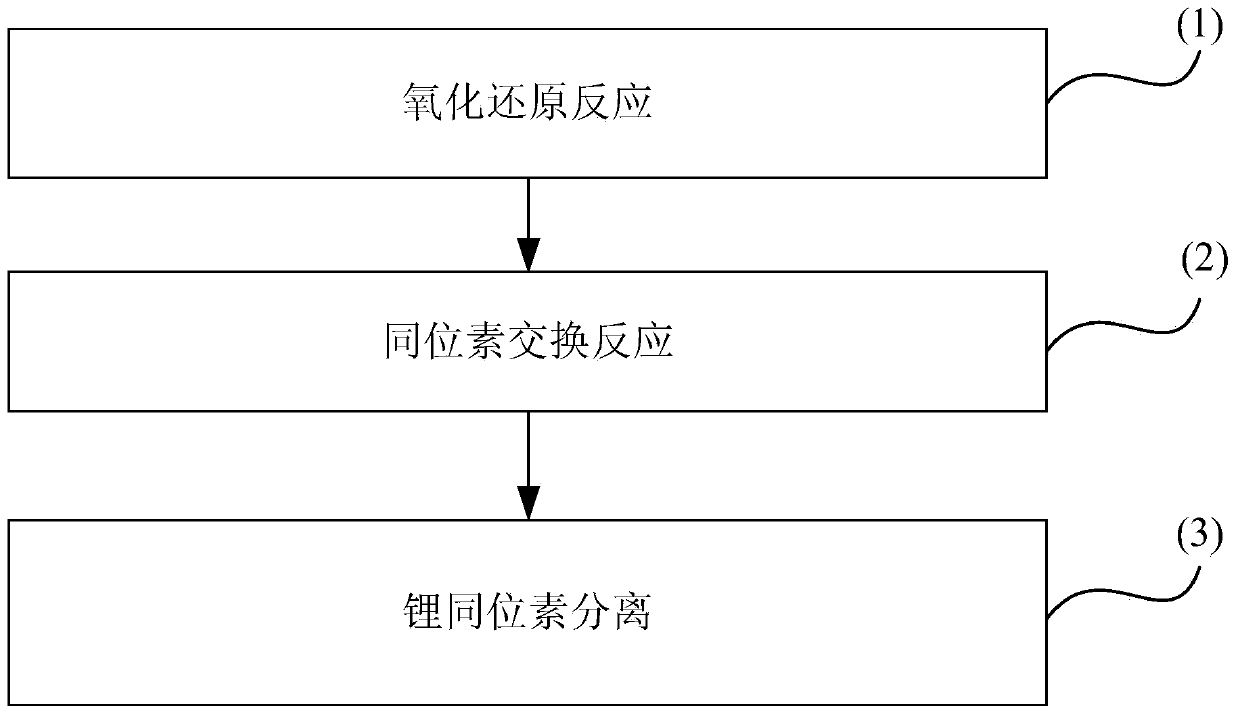

[0035] (1) Redox reaction

[0036] A graphite sheet with a thickness of 0.2mm is used as the working electrode (WE), a Pt sheet electrode is used as the auxiliary electrode (CE), and a saturated calomel electrode is used as the reference electrode (RE). The electrolyte solution has a concentration of 0.05mol / L Lithium acetate-dimethylsulfoxide (LiCH 3 COO-DMSO) solution. The electrolysis conditions are: first perform electrolysis in the constant current mode with a current size of -0.8mA, and when the voltage of the working electrode to the reference electrode drops to a stable voltage of -3.0V, the electrolysis mode is converted to a c...

Embodiment 2

[0046] The same as the principle and method in Example 1, the difference is that the parameters change, and the following parameters in Example 1 in Example 1 are still implemented after the implementation, as shown in the following table:

[0047]

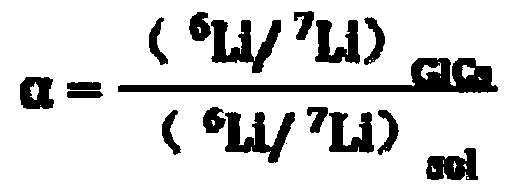

[0048] In the above-mentioned embodiment, the electrolytic system of graphite flake working electrode and lithium acetate-dimethyl sulfoxide electrolyte is used to realize the separation of lithium isotopes in the non-mercury system, and the single-stage separation coefficient reaches more than 1.02, which can reach the industrial level. Requirements for single-stage separation coefficients for lithium isotope separation. And the reaction in the embodiment is an exchange reaction between lithium isotopes in different valence states, which is very beneficial to obtain a higher single-stage separation coefficient. In addition, since there is no complicated chemical reaction in the embodiment, and the reaction is a solid-liquid tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com