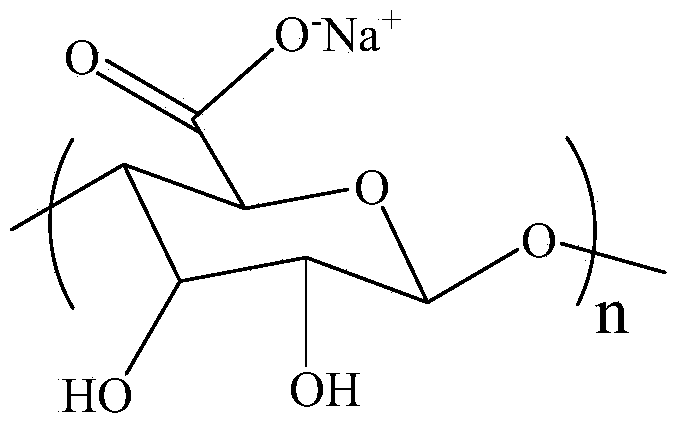

Sodium alginate chiral cross-linked membrane and applications thereof

A technology of sodium alginate and dry film, which is applied in the field of sodium alginate chiral cross-linked film, can solve the problems of sodium alginate chiral cross-linked film that have not yet been seen, and achieve easy large-scale industrial production, easy continuous operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

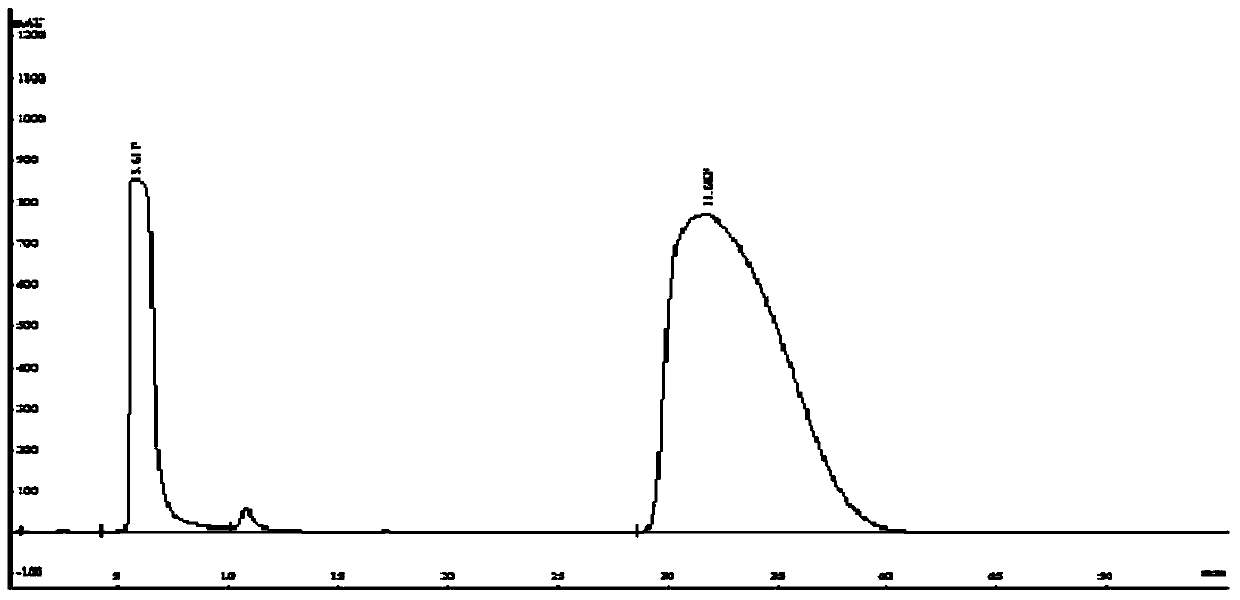

Image

Examples

Embodiment 1

[0030] Commercial sodium alginate was used as raw material, dissolved in 2wt.% acetic acid aqueous solution to make the concentration 5wt.%; stirred and dissolved, ultrasonicated for 30 minutes to remove aggregated particle molecules, and left to defoam; at room temperature, pour the casting solution on a smooth surface Scrape the film with a scraper on a glass plate and dry it at room temperature for 4 days; cross-link the dry film with an acetone cross-linking agent containing 5% glutaraldehyde and 0.1% hydrochloric acid; properties; that is, to obtain the desired sodium alginate chiral cross-linked membrane.

Embodiment 2

[0036] Commercial sodium alginate was used as raw material, dissolved in 2wt.% acetic acid aqueous solution to make the concentration 5wt.%; stirred and dissolved, ultrasonicated for 30 minutes to remove aggregated particle molecules, and left to defoam; at room temperature, pour the casting solution on a smooth surface On a glass plate, scrape the film with a scraper and dry it at room temperature for 4 days; cross-link the dry film with a 6.7% 1,6-hexamethylene diisocyanate n-heptane solution; rinse with a large amount of heptane, acetone, and water in sequence To neutral; that is, to obtain the desired sodium alginate chiral cross-linked membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com