Preparation method and separation method of surfactant containing amino terminal and diamine group

The technology of a surfactant and a separation method, which is applied in the field of preparation of surfactants, can solve the problems of cumbersome preparation process, difficult separation process, complicated separation operation, etc., and achieves the effects of simple operation process, saving human resources, and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

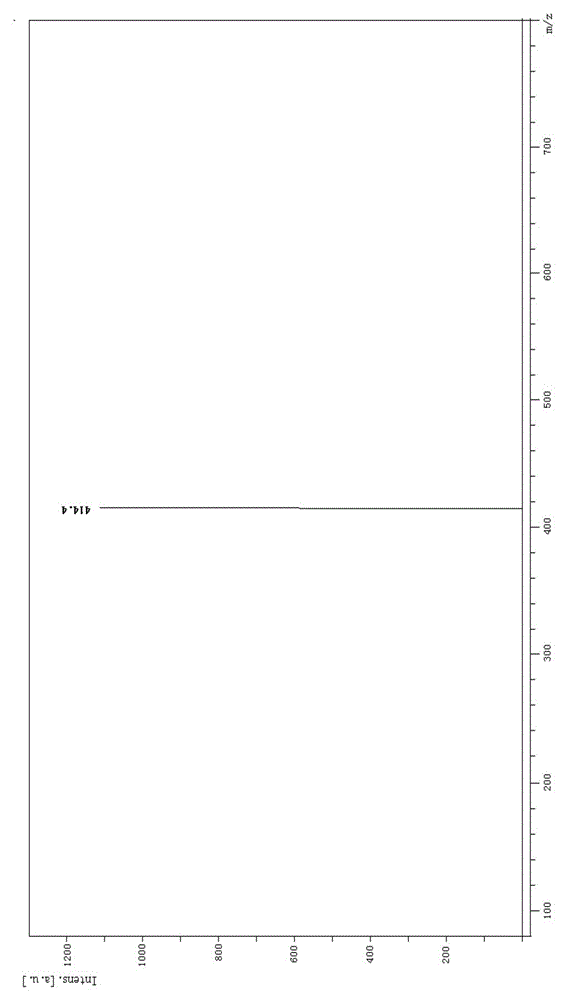

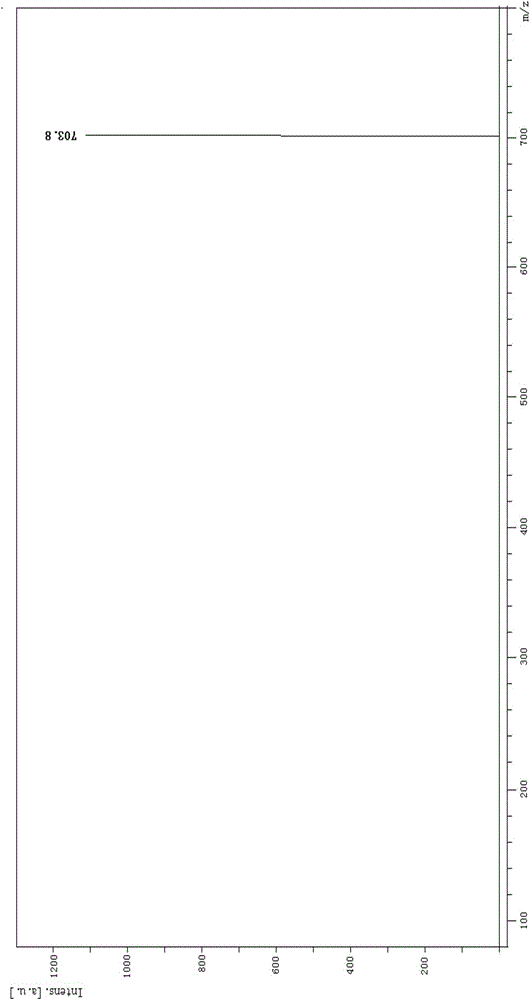

Image

Examples

Embodiment 1

[0032] The route of preparing the tensio-active agent containing amino terminal and diamine group by octadecanoic acid is:

[0033]

[0034] Add octadecanoic acid solid and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solid and 1-hydroxybenzotriazole solid in the round bottom flask, then add dichloromethane to dissolve, Stir evenly at room temperature to obtain a mixed solution; slowly drop the mixed solution into 1,2-(2-aminoethoxy)ethane through a constant-pressure dropping funnel, and carry out a stirring reaction under an ice-salt bath (can be obtained through a high-efficiency Thin-layer chromatography silica gel plate to monitor the reaction), after the reaction is completed, pour the obtained reaction solution into saturated saline, at this time, a white jelly-like small molecule gel is precipitated; the dichloromethane in the white jelly-like small molecule gel is filtered and water to obtain a white solid, which is a mixture of amino-terminated and diamine-based s...

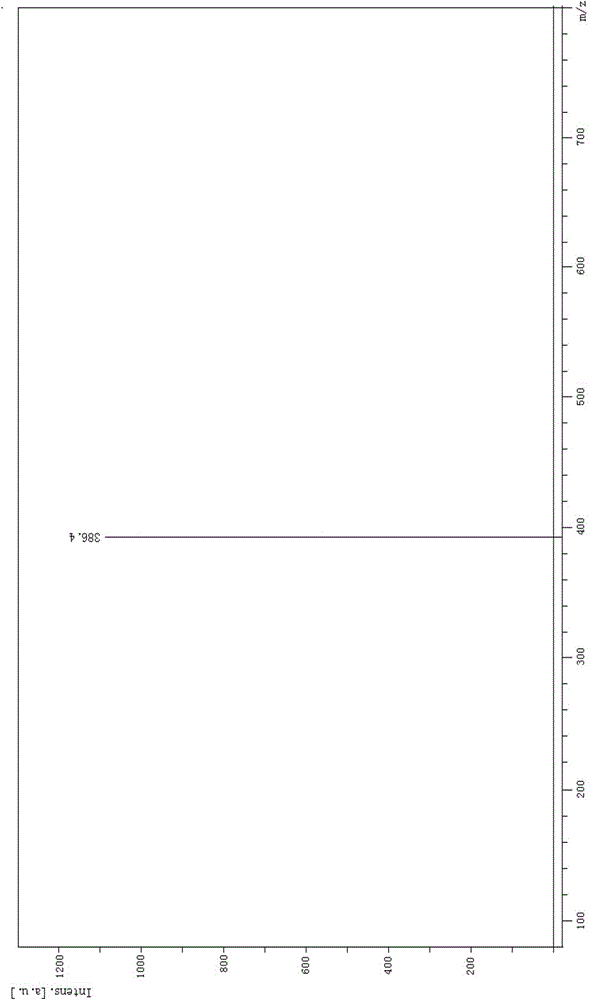

Embodiment 2

[0046] The preparation of a mixture of surfactants containing amino-terminal and diamine groups is basically the same as in Example 1, except that octadecanoic acid is replaced by hexadecanoic acid to obtain a mixture of surfactants containing amino-terminal and diamine groups.

[0047] When the mixture is added dropwise to 1,2-(2-aminoethoxy)ethane, hexadecanoic acid solid: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solid : When the molar ratio of 1-hydroxybenzotriazole solid: 1,2-(2-aminoethoxy)ethane is 1:1:1:4, the surface activity of the amino-terminal and diamine-containing In the mixture of agents, the surfactant containing amino terminal accounts for 90-95% of the mass of the mixture, and the surfactant containing diamine groups accounts for 5-10% of the mass of the mixture.

[0048] When the mixture is added dropwise to 1,2-(2-aminoethoxy)ethane, hexadecanoic acid solid: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solid : When the molar ratio of 1-hydroxybenzotr...

Embodiment 3

[0053] The preparation of the mixture of surfactants containing amino-terminal and diamine groups is basically the same as in Example 1, except that octadecanoic acid is replaced by myristic acid to obtain a mixture of surfactants containing amino-terminal and diamine groups.

[0054] When the mixture is added dropwise to 1,2-(2-aminoethoxy)ethane, among which myristic acid solid: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solid : When the molar ratio of 1-hydroxybenzotriazole solid: 1,2-(2-aminoethoxy)ethane is 1:1:1:4, the surface activity of the amino-terminal and diamine-containing In the mixture of agents, the surfactant containing amino terminal accounts for 90-92% of the mass of the mixture, and the surfactant containing diamine groups accounts for 8-10% of the mass of the mixture.

[0055] When the mixture is added dropwise to 1,2-(2-aminoethoxy)ethane, among which myristic acid solid: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solid : When the molar ratio of 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com