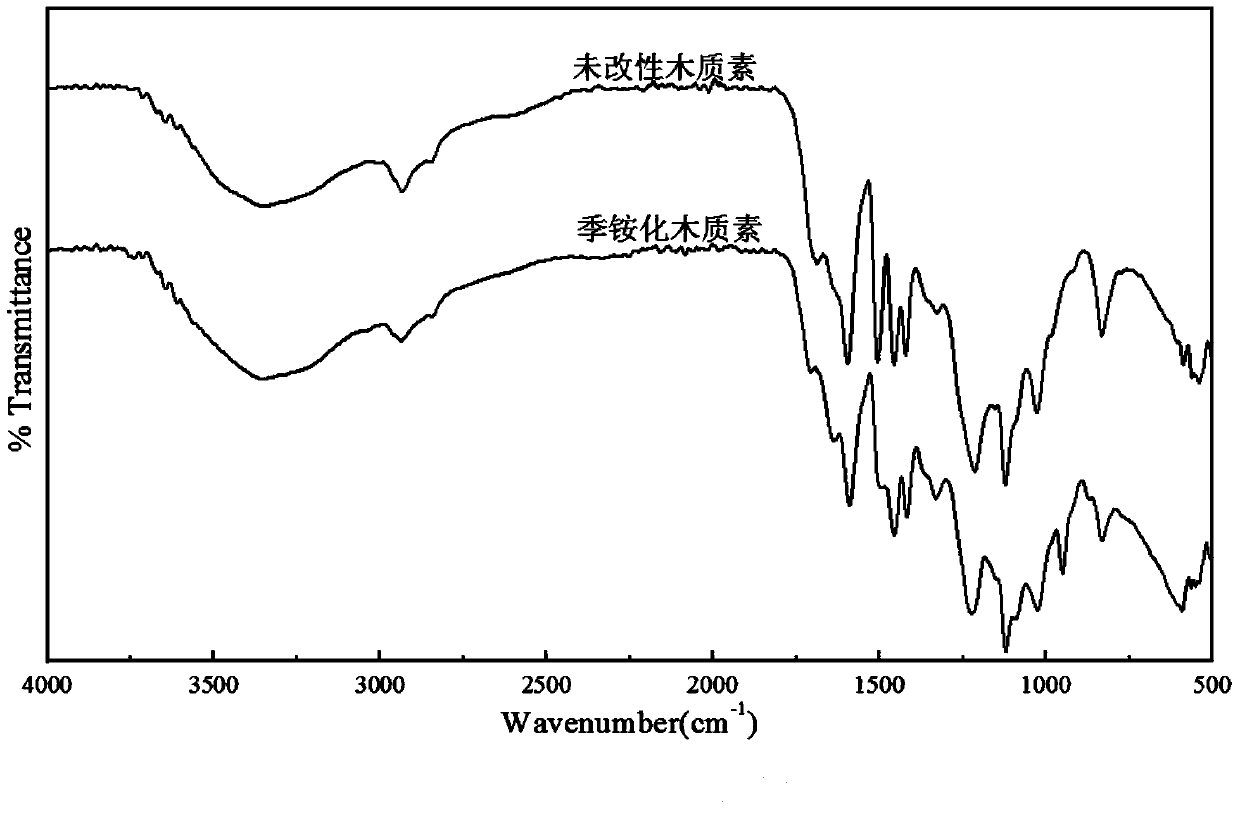

Method for modifying lignin in eutectic solvent through quaternization

A technology of quaternization modification and deep eutectic solvent, applied in the production of bulk chemicals, etc., can solve the problems of using toxic reagents and harsh reaction conditions, and achieve the effect of easy control of reaction conditions and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1. Vacuum-dry choline chloride and urea at 80°C for 12 hours, accurately weigh a certain mass of choline chloride and urea at a molar ratio of 1:2, and stir magnetically at 80°C until Light yellow transparent liquid, enzymatic lignin is added to 0.1mol / L sodium hydroxide solution at a mass ratio of 20:100, after the lignin is completely dissolved, 1mol / L hydrochloric acid is added drop by drop under stirring until the pH value of the solution is 1 ~2, keep warm at 70°C for 30 minutes, filter, wash with water, and dry to obtain purified lignin. Add 0.1g of purified lignin to 5g of deep eutectic solvent, add 0.4g of sodium hydroxide after the lignin is dissolved, and react at 90°C for 5h, and after the reactant is cooled, add 20g of potassium ferricyanide with a mass fraction of 10% The aqueous solution is filtered, washed with water and dried to obtain quaternized modified lignin.

Embodiment 2

[0015] Example 2, vacuum-dry choline chloride and urea at 80°C for 12 hours, accurately weigh a certain mass of choline chloride and urea at a molar ratio of 1:2, and stir magnetically at 80°C until Light yellow transparent liquid, enzymatic lignin is added to 0.1mol / L sodium hydroxide solution at a mass ratio of 20:100, after the lignin is completely dissolved, 1mol / L hydrochloric acid is added drop by drop under stirring until the pH value of the solution is 1 ~2, keep warm at 70°C for 30 minutes, filter, wash with water, and dry to obtain purified lignin. Add 0.3g of purified lignin to 5g of deep eutectic solvent, add 0.4g of sodium hydroxide after the lignin is dissolved, and react at 90°C for 10h, and after the reactant is cooled, add 20g of potassium ferricyanide with a mass fraction of 10% The aqueous solution is filtered, washed with water and dried to obtain quaternized modified lignin.

Embodiment 3

[0016] Example 3. Vacuum-dry choline chloride and urea at 80°C for 12 hours, accurately weigh a certain mass of choline chloride and urea at a molar ratio of 1:2, and stir magnetically at 80°C until Light yellow transparent liquid, enzymatic lignin is added to 0.1mol / L sodium hydroxide solution at a mass ratio of 20:100, after the lignin is completely dissolved, 1mol / L hydrochloric acid is added drop by drop under stirring until the pH value of the solution is 1 ~2, keep warm at 70°C for 30 minutes, filter, wash with water, and dry to obtain purified lignin. Add 0.5g of purified lignin to 5g of deep eutectic solvent, add 0.4g of sodium hydroxide after the lignin is dissolved, react at 90°C for 20h, and after the reactant is cooled, add 20g of potassium ferricyanide with a mass fraction of 10% The aqueous solution is filtered, washed with water and dried to obtain quaternized modified lignin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com