A kind of low odor glass fiber reinforced polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of low-odor glass fiber reinforced polypropylene composite material and its preparation, achieves the effects of simple preparation process, low cost and odor removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

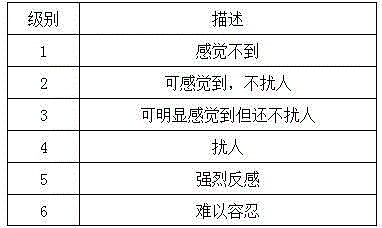

Image

Examples

preparation example Construction

[0046] Preparation of jellyfish pellets:

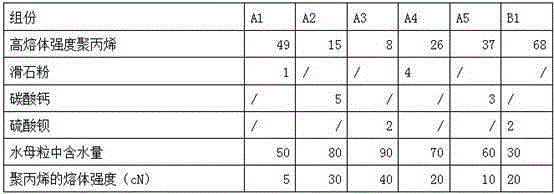

[0047]Fully mix high-melt-strength polypropylene with different melt strengths and mineral fillers (talc powder, calcium carbonate or barium sulfate) according to the ratio shown in Table 1, extrude strip-shaped polypropylene in an extruder, and then Shred it into polypropylene pre-expanded granules; use water as a foaming agent to foam the polypropylene pre-expanded granules to prepare expanded polypropylene with high melt strength; Polypropylene and water were mixed in a high-speed mixer for 5-10 minutes. By controlling the mixing time, jellyfish particles with the water content shown in Table 1 were prepared and released for use.

[0048] Each component content (percentage by weight) of jellyfish grain of table 1

[0049]

Embodiment 1-5

[0051] A kind of low odor glass fiber reinforced polypropylene composite material, its raw material formula is as shown in table 3, and its preparation method comprises the following steps:

[0052] (1) Weigh the polypropylene, compatibilizer, mineral filler and additives according to the weight percentage, and mix them in a high-speed mixer for 1-3 minutes; mix them evenly to obtain a premix;

[0053] (2) Put the premix into the main feeding port of the twin-screw extruder, add jellyfish pellets from the side feeding port, and feed the glass fiber from the side feeding port of the extruder, melt extrude, and granulate dry. Its performance test is shown in Table 4.

[0054] Among them, the copolymerized polypropylene in Example 1: AS164 (melt flow rate (230°C / 2.16kg) is 1.5g / 10min) selected from Singapore Polyolefin Company; the homopolymerized polypropylene is selected from EP540V (melt flow rate) of Moplen The rate (230°C / 2.16kg) is 87g / 10min).

Embodiment 2

[0055] Homopolypropylene in Example 2: selected from Sinopec Maoming HC9012-M (melt flow rate (230°C / 2.16kg) is 10g / 10min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com