Low-temperature-resistant insulating impregnating resin and preparation method thereof

A technology of insulating impregnation and low temperature resistance, which is applied in the field of low temperature resistant insulating impregnating resin and its preparation, which can solve problems such as defects in the insulation system, affecting the motor, and affecting the operation of the motor, and achieve excellent high and low temperature (liquid nitrogen-room temperature) impact performance , Good electrical properties, low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

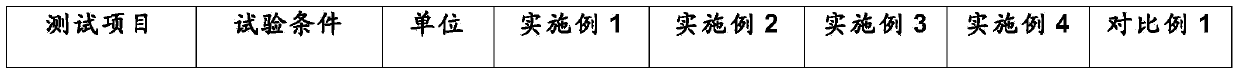

Examples

Embodiment 1

[0036] This example provides a low temperature resistant insulating impregnation resin, which is prepared through the following steps:

[0037] (1) Preparation of polyurethane epoxy resin: Treat the raw materials to a water content below 0.1%, then add 30g of poly(tetramethylene-co-ethylene ether) glycol with a number average molecular weight of 2000, 10g of hexamethylene Isocyanate, heated to 80°C, reacted under nitrogen protection for 2 hours. Then 2g of 1,4-butanediol was added, and the reaction was continued for 3 hours at 80°C under the protection of nitrogen to obtain a polyurethane prepolymer. Add 100g hydantoin epoxy resin into the polyurethane prepolymer, heat to 60°C, and react under nitrogen protection for 2 hours to obtain polyurethane epoxy resin.

[0038] (2) Preparation of low temperature resistant insulating impregnating resin: weigh 100g of E-51 epoxy resin, 40g of polyurethane epoxy resin prepared in step A, 30g of phenolic hydroxyl-terminated low molecular ...

Embodiment 2

[0040] This example provides a low temperature resistant insulating impregnation resin, which is prepared through the following steps:

[0041] (1) Preparation of polyurethane epoxy resin: Treat the raw materials to a water content below 0.1%, then add 15g of poly(tetramethylene-co-ethylene ether) glycol with a number average molecular weight of 1200, 8g of hexamethylene Isocyanate, heated to 70°C, reacted under nitrogen protection for 3 hours. Then 1 g of 1,4-butanediol was added, and the reaction was continued for 3 hours at 80° C. under the protection of nitrogen to obtain a polyurethane prepolymer. Add 100g hydantoin epoxy resin to the polyurethane prepolymer, heat to 70°C, and react for 1 hour under the protection of nitrogen to obtain polyurethane epoxy resin.

[0042] (2) Preparation of low temperature resistant insulating impregnation resin: weigh 150g of F-51 epoxy resin, 90g of polyurethane epoxy resin, 60g of low molecular weight polyphenylene ether with terminal p...

Embodiment 3

[0044] This example provides a low temperature resistant insulating impregnation resin, which is prepared through the following steps:

[0045](1) Preparation of polyurethane epoxy resin: Treat the raw materials to a water content below 0.1%, then add 20 g of poly(tetramethylene-co-ethylene ether) glycol with a number average molecular weight of 1500, 5 g of hexamethylene Isocyanate, heated to 60°C, reacted under nitrogen protection for 4 hours. Then 3g of 1,4-butanediol was added, and the reaction was continued for 1 hour under the protection of nitrogen at 90°C to obtain a polyurethane prepolymer. Add 100g hydantoin epoxy resin to the polyurethane prepolymer, heat to 60°C, and react for 2 hours under the protection of nitrogen to obtain polyurethane epoxy resin.

[0046] (2) Preparation of low temperature resistant insulating impregnation resin: weigh 100g of E-54 epoxy resin, 80g of polyurethane epoxy resin, 40g of low molecular weight polyphenylene ether with terminal phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com