Straw methane fermentation system

A biogas fermentation and straw technology, which is applied in bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, gas production bioreactors, etc. Inability to promote large-scale and other problems, to achieve the effect of simplifying the raw material preparation process, improving convenience, and enhancing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

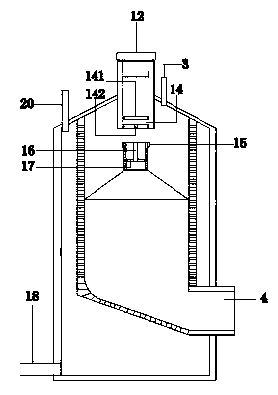

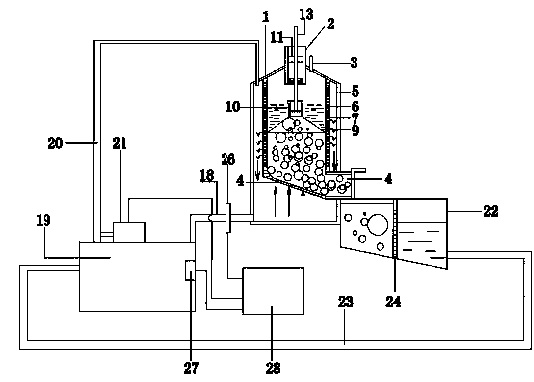

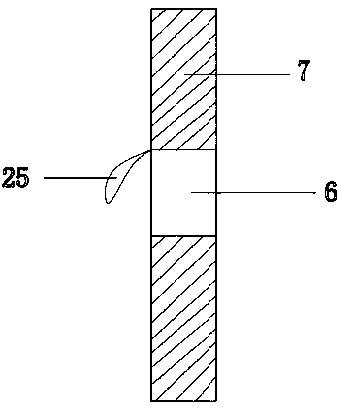

[0028] Such as Figure 1-3 As shown, the straw biogas fermentation system described in this embodiment includes a fermentation tank 1, the top of the fermentation tank 1 is provided with a feed pipe 2 and a biogas pipe 3, and the bottom of the fermentation tank 1 is provided with a slagging outlet 4, which is characterized in that The tank body of the fermentation tank 1 is a double-layer three-section cylindrical structure, the outer layer is the outer pool wall 5, and the inner layer is a cylindrical partition with drainage holes 6 evenly distributed on the plate surface and coaxial with the outer pool wall 5. Plate 7, the upper end of the partition 7 extends to the top of the fermentation tank 1, and is connected with it to share the top, a space for containing the biogas slurry is reserved between the inner and outer layers, and the lower end of the partition 7 is provided with a separate bottom plate 8, the bottom plate 8 is connected with the separator 7 in a smooth tran...

Embodiment 2

[0030] Such as Figure 1-3 As shown, the straw biogas fermentation system described in this embodiment includes the components and structures described in Embodiment 1, and also includes a feeding and pressing device, which includes a feeding pipe 2, a conical pressing cover 9, and a tubular connector 10. Anti-splash plug 11, sealing cover 12, and pressing rod 13; feeding pipe 2 is set on the top of fermentation tank 1, and a ring-shaped buckle 14 is arranged inside the bottom end of the pipe extending into fermentation tank 1. The ring-shaped buckle 14 is composed of two rings 141 fixed inside the feed pipe 2. There is a gap between the two rings 141, and the ring 141 on the lower side is provided with two gaps 142; the tubular connector 10 is fixed Installed on the upper end of the truncated conical pressing cover 9, its diameter is smaller than the feed pipe 2, and the upper edge of the tubular connector 10 is symmetrically provided with two stoppers 15, which are connected...

Embodiment 3

[0032] Such as Figure 1-3 As shown, the straw biogas fermentation system described in this embodiment includes the components and structures described in Embodiment 2, and also includes an external circulation device for biogas slurry. The external circulation device for biogas slurry includes a drain pipe 18, and communicates with the drain pipe 18 A liquid storage tank 19, and a biogas slurry return pipe 20 is also arranged on the top of the fermentation tank 1. The biogas slurry in the liquid storage tank 19 is transported to the return tank through a water pump 21, and finally enters the space between the inner and outer layers of the fermentation tank 1 , improve the fluidity of the biogas slurry, and promote the fermentation. The straw biogas fermentation system also includes a slag-liquid separation and recovery device, which is composed of a slag-liquid separation tank 22 and a biogas slurry delivery pipe 23. The slag-liquid separation tank 22 is an inclined container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com