Covalent bond tinting method applicable to silks

A covalent bond and silk technology, applied in dyeing, textile and papermaking, etc., can solve the problems of difficulty in dark color and single coupling components, and achieve the effects of small damage, low development cost and complete chromatogram.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

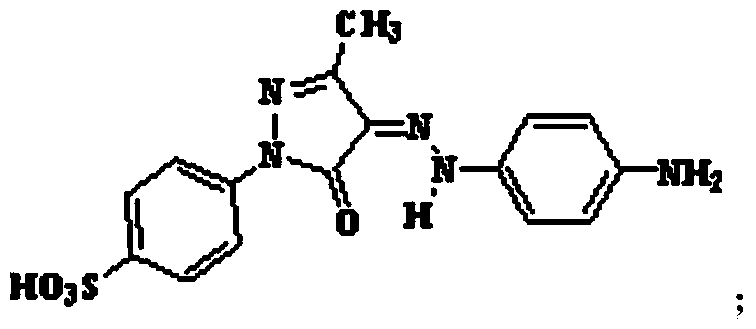

[0031] Embodiment 1, a kind of covalent bond coloring method that is applicable to silk, selects the dyestuff that contains primary aromatic amine group as yellow dyestuff, and its structural formula is as follows:

[0032]

[0033] Formaldehyde is specifically selected as the aldehyde substance.

[0034] The coloring method is as follows:

[0035] Add 5g (0.0134mol) of dye and 0.0134mol of formaldehyde to 1000g of mulberry silk fabric; the dyeing bath ratio is 1:50; the pH value of the dyeing bath is 6.5 (use acetic acid-sodium acetate buffer solution to adjust the above pH value, this It is a conventional technique), the dyeing temperature is 40°C, and the holding time is 20 hours.

[0036] After dyeing, it is washed with deionized water at 60°C and 15°C to remove impurities adsorbed on the silk (just wash the floating color of the dye and formaldehyde from the silk), and then dry it in the air (until it reaches constant weight at room temperature) .

[0037] It is mea...

Embodiment 2

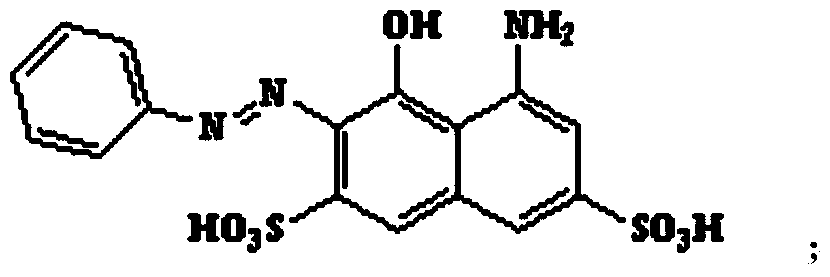

[0038] Embodiment 2, a kind of covalent bond coloring method that is applicable to silk, selects the dyestuff that contains primary aromatic amine group as red dyestuff, and its structural formula is as follows:

[0039]

[0040] The aldehyde substance is specifically selected from acetaldehyde.

[0041] The coloring method is as follows:

[0042] Add 30g (0.07mol) of dye and 0.14mol of acetaldehyde to 1000g of mulberry silk fabric; the dyeing bath ratio is 1:100; the pH value of the dyeing bath is 4.0, the dyeing temperature is 30°C, and the holding time is 24 hours.

[0043] After the dyeing is finished, it is washed with deionized water at 60°C and 15°C to remove impurities adsorbed on the silk, and dried in the air.

[0044] It is measured that the maximum absorption wavelength of the dye (water soluble) is 530nm, and the maximum absorption wavelength after dyeing the fabric is 540nm. The silk after the method described in Example 2 is processed according to the nation...

Embodiment 3

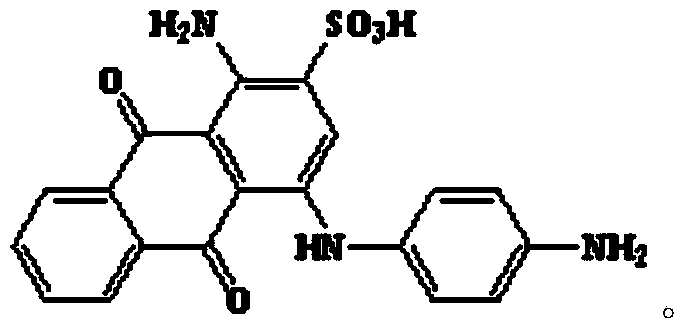

[0045] Embodiment 3, a kind of covalent bond coloring method that is applicable to silk, selects the dyestuff containing primary aramide group as blue dyestuff, and its structural formula is as follows:

[0046]

[0047] The aldehyde substance is specifically selected from propionaldehyde.

[0048] The coloring method is as follows:

[0049]Add 20g (0.049mol) of dye and 0.07mol of propionaldehyde to 1000g of pressed silk fabric; the dyeing bath ratio is 1:20; the pH value of the dyeing bath is 6.0, the dyeing temperature is 70°C, and the holding time is 0.5 hours.

[0050] After the dyeing is finished, it is washed with deionized water at 60°C and 15°C to remove impurities adsorbed on the silk, and dried in the air.

[0051] It is measured that the maximum absorption wavelength of the dye (water soluble) is 628nm, and the maximum absorption wavelength after dyeing the fabric is 630nm. The silk after the method described in Example 3 is processed according to the national s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com