Putting-type transient temperature recorder

A transient temperature and recorder technology, applied in the field of drop-in transient temperature recorders and integrated drop-in transient temperature recorders, can solve the problems of insufficient shock resistance, slow response speed, attenuation, etc. The effect of easy measurement, small form factor, and complete temperature parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. Inserting type transient temperature recorder

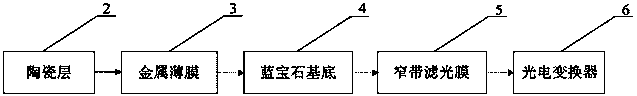

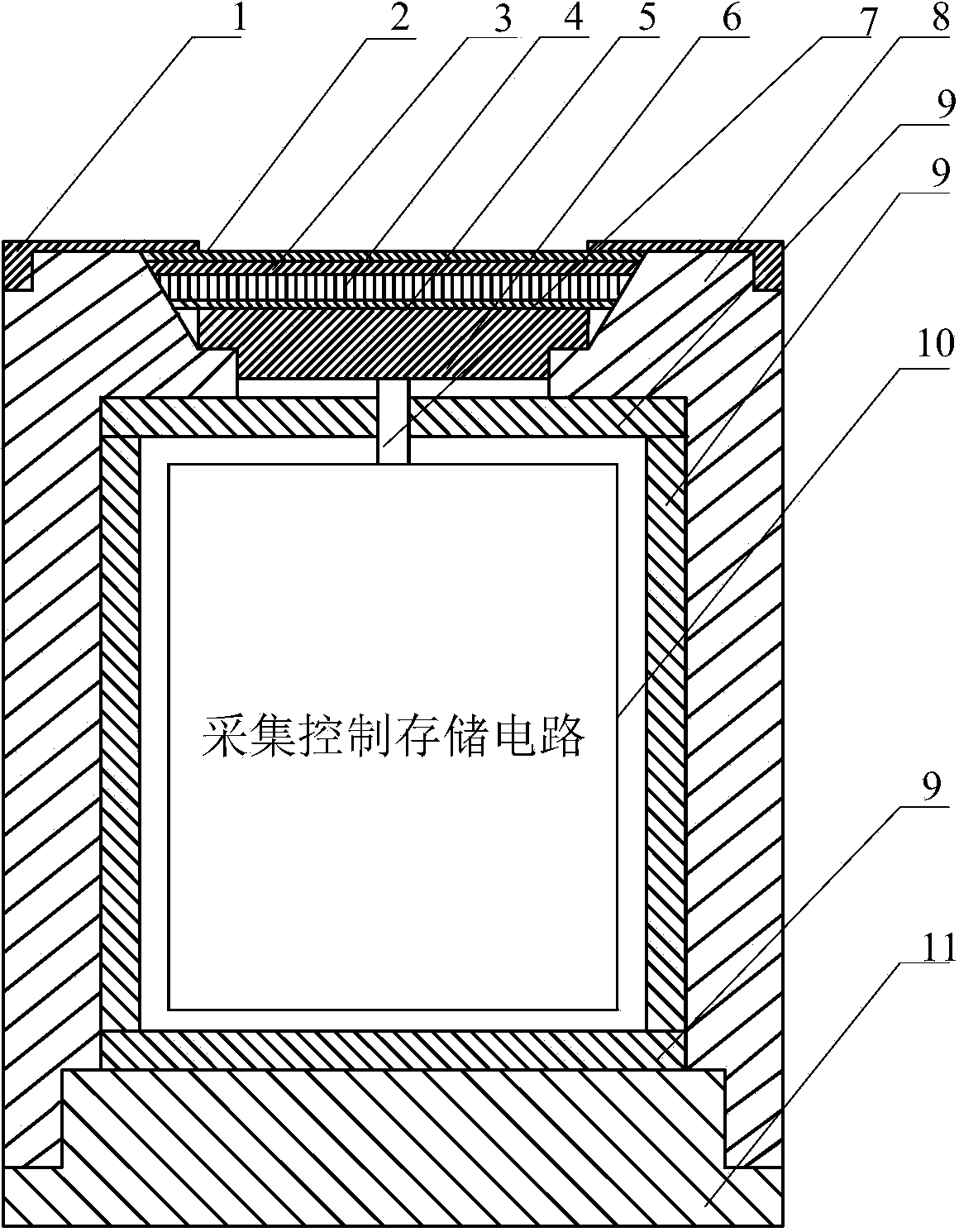

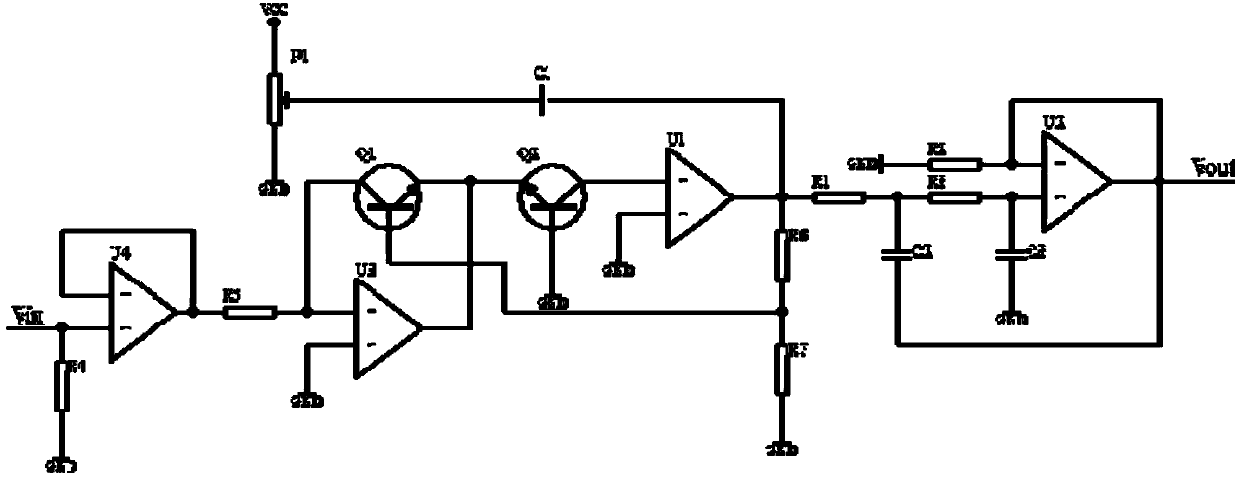

[0024] The drop-in transient temperature recorder of this example is composed of the recorder shell and the temperature sensitive unit inside the shell and the acquisition control storage circuit unit. The physical structure of the recorder in this example is given by figure 1 show, figure 1 It is a schematic diagram of the structure of the embedded temperature transient recorder. figure 1 Middle: 1 is the protective cover, 2 is the ceramic layer, the thickness is 1.0-20.0μm, 3 is the metal film, the thickness is 1.0-50.0μm, 4 is the sapphire substrate, the thickness is 1.0-10.0mm, 5 is the narrow-band filter film, The thickness is 10.0-100.0nm, 6 is a photoelectric converter, 7 is a wire, 8 is a mechanical casing, 9 is a buffer rubber pad, 10 is an acquisition control storage circuit, and 11 is a casing cover. figure 2 Shown is the block diagram of the temperature sensitive unit structure, figure 2 Mi...

Embodiment 2

[0025] Embodiment 2. Inserting type transient temperature recorder

[0026] The specific structure of the drop-in transient temperature recorder in this example can be Figure 1 ~ Figure 4 etc. jointly show that the difference between the embedded transient temperature recorder of this example and the embedded transient temperature recorder of Embodiment 1 is: this example deposits a metal film 3 on the front surface of the sapphire substrate, and the metal film It can be made of metal iridium or platinum; a ceramic layer 2 with high thermal conductivity is deposited on the metal film, and the ceramic layer can be made of boron carbide B 4 C, or silicon nitride Si 3 N 4 Manufacture; a narrow-band filter film 5 is plated on the rear surface of the sapphire substrate by a pulsed laser deposition process, and the narrow-band filter film can be made of silicon dioxide SiO 2 manufacture. All the rest of the embedded transient temperature recorder of this example are the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com