Algan/gan MISHEMT high voltage device based on composite drain and its manufacturing method

A technology of composite drain and high voltage devices, applied in the field of microelectronics, can solve problems such as large on-resistance, achieve the effects of improving breakdown voltage, good controllability and repeatability, and avoiding gate leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

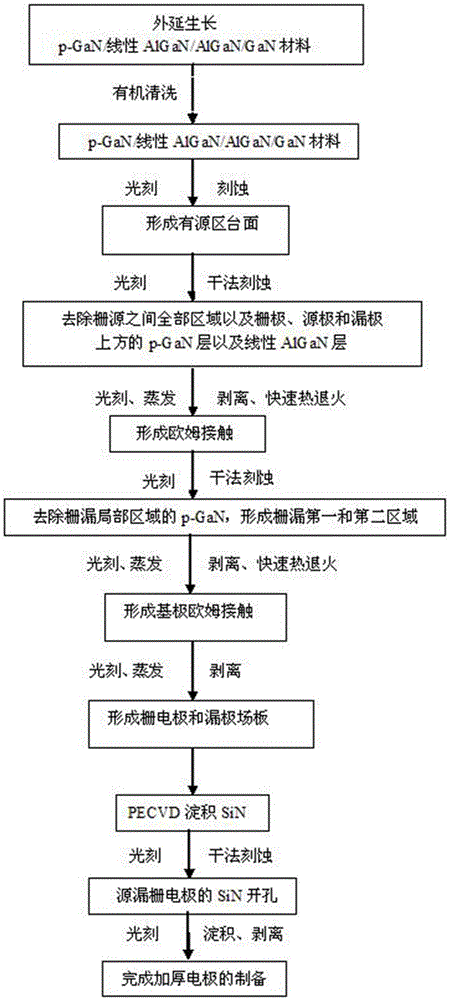

[0040] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

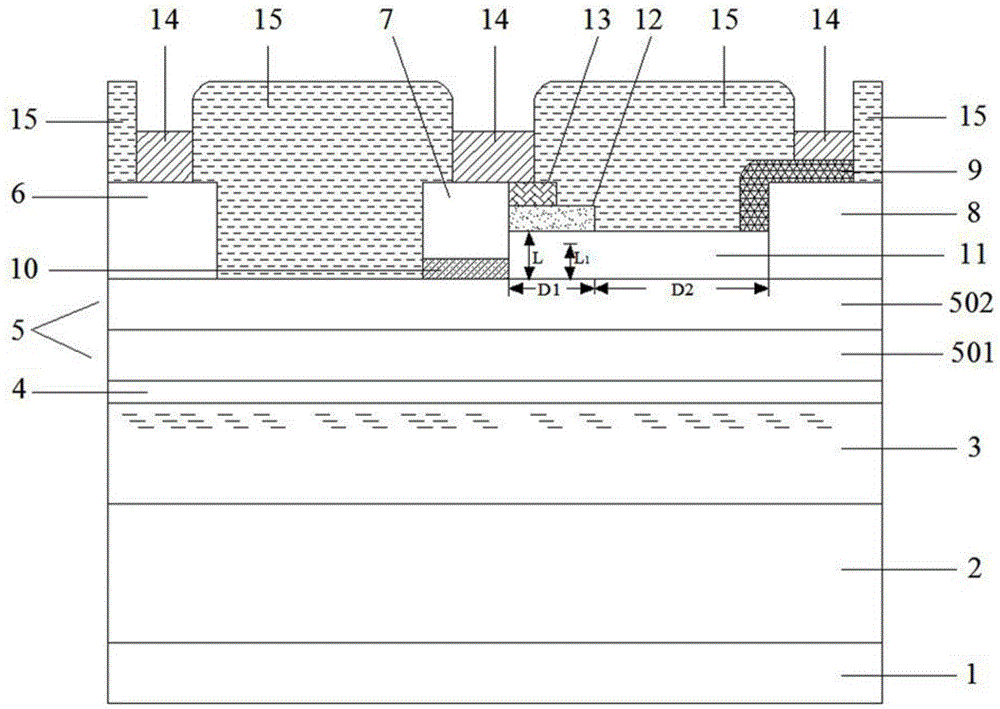

[0041] First, the structure of the AlGaN / GaN MISHEMT high voltage device based on the composite drain of the present invention is introduced.

[0042] refer to figure 1 , the AlGaN / GaNMISHEMT high-voltage device based on the composite drain of the present invention, its structure includes from bottom to top: substrate 1, GaN buffer layer 2, intrinsic GaN channel layer 3 (intrinsic GaN channel layer 3 can also be used AlGaN channel layer replacement), AlN isolation layer 4 and AlGaN barrier layer 5, AlGaN barrier layer 5 is composed of lower i-type AlGaN layer 501 and upper n-type AlGaN layer 502, wherein, the upper edge of AlGaN barrier layer 5 In the horizontal direction, there are: source 6, gate 7 and composite drain, and an insulating dielectric layer 10 is arranged between the gate 7 and the AlGaN barrier layer 5, and the insulating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com