Artificial heart valve and valve leaflet manufacturing method

A valve leaflet, artificial heart technology, applied in the field of medical devices, can solve the problems of difficult to remove residual tissue debris, difficult to operate, easy to deform, etc., to ensure the bending and stretching effect, improve the output rate, easy to fix and process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing artificial heart valve leaflets. By freezing animal tissue membranes and then processing, artificial heart valve leaflets of required thickness can be obtained conveniently, the output rate of animal tissue membrane leaflets can be improved, and the Retain the original elasticity of animal tissue membrane.

[0031] Pretreatment before freezing:

[0032] Because the animal tissue membrane used contains a certain amount of water, it is usually necessary to pre-treat the animal tissue membrane before freezing, which is more conducive to protecting the structural integrity of the animal tissue membrane. Pretreatment before freezing can be performed directly on the whole piece of animal tissue, or on animal tissue cut into the shape of a leaflet. The pretreatment before freezing is to immerse the animal tissue membrane in a cryoprotectant. The cryoprotectant can be substances such as glycerin, dimethyl sulfoxide, ethylene glyco...

Embodiment 1

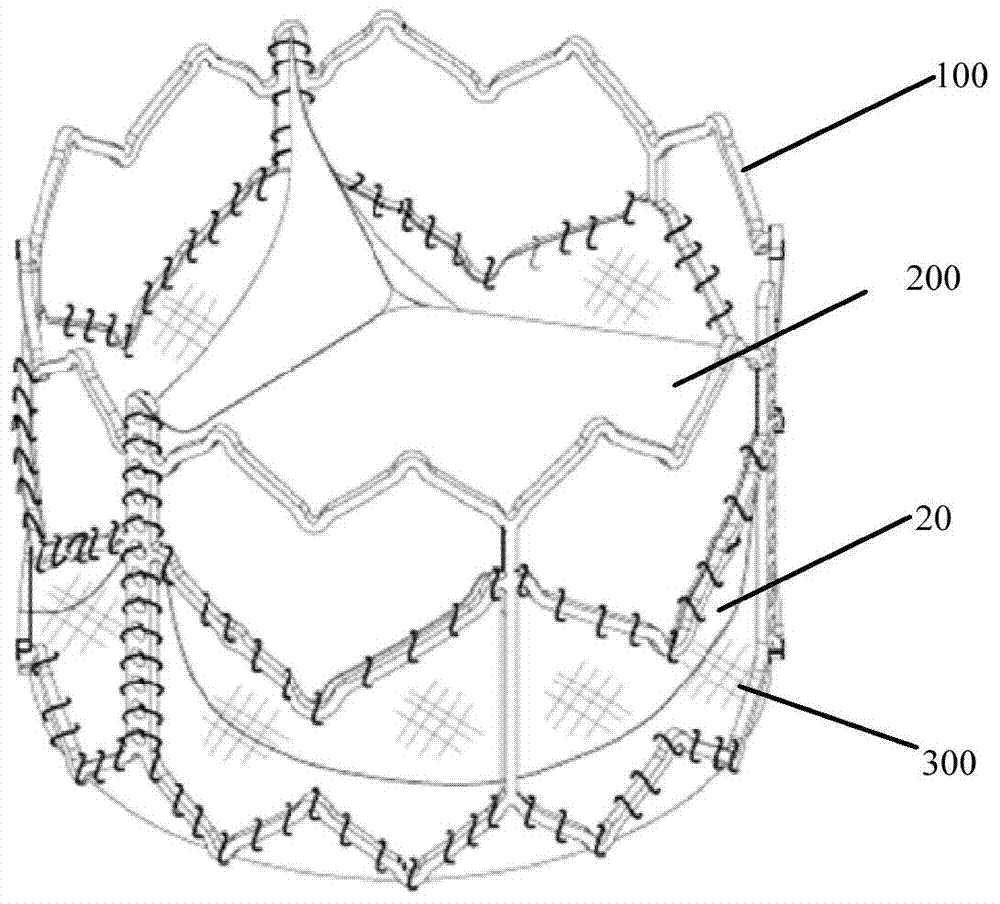

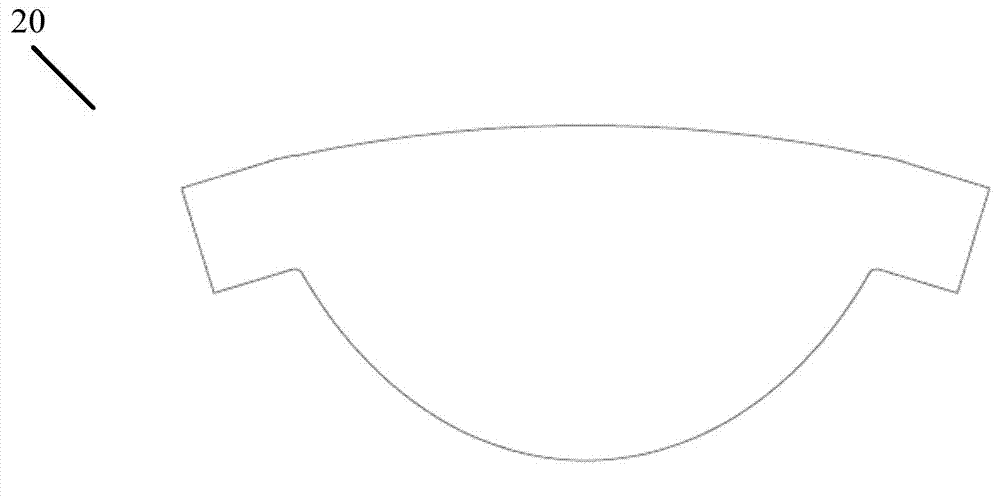

[0047] This embodiment provides a method for preparing artificial heart valve leaflets. figure 1 It is a schematic diagram of the structure of an artificial interventional valve. The valve comprises a cylindrical frame 100 , a leaflet structure 200 with 3 leaflets and a suture skirt 300 . The leaflet structure 200 is arranged inside the cylindrical frame 100, wherein each leaflet has figure 2 The shape shown, and fixed to the cylindrical frame 100 by sutures. The suture skirt 300 is disposed circumferentially between the cylindrical frame 100 and the leaflet structure 200 .

[0048] Wherein, the preparation process of leaflet 20 is as follows: Figure 4 As shown, the bovine pericardial slice 1 (its thickness is between 0.3-0.8 mm) collected as the valve leaflet is pretreated before freezing, and then put into the basket 2. The above-mentioned pericardial slice 1 can be The cross-linked pericardial slice is beneficial to improve the tissue stability of the pericardial slic...

Embodiment 2

[0051] This embodiment provides a method for preparing artificial heart valve leaflets, which can be used for the interventional valve as described in Embodiment 1, and can also be applied to other biological valves using animal pericardium as leaflets.

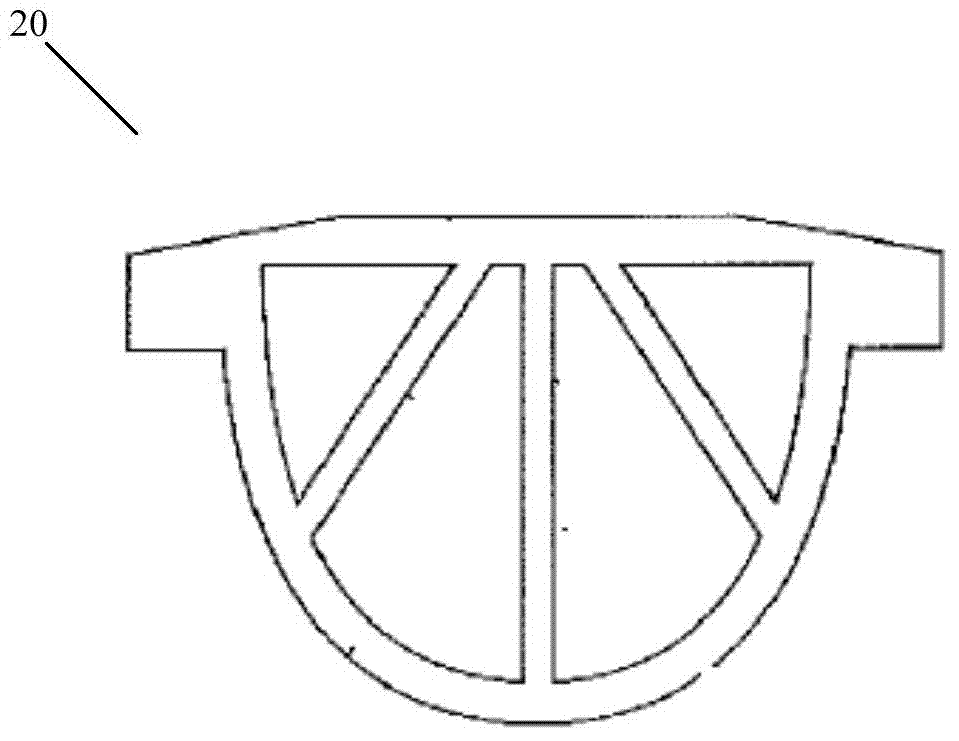

[0052] Wherein, the preparation method of leaflet 20 can still be as follows: Figure 4 As shown, bovine pericardial slices were cut into leaflet shapes; the pericardial slices 1 with leaflet shapes whose thickness in each part was greater than the final required thickness were selected, and pre-treated before freezing; Leaf-shaped pericardium piece 1 put Figure 6 In the shown die, make the pericardial sheet 1 smooth face downward when putting in; The shape of the groove in the said die is the same as the leaflet profile, and the depth of the groove is the setting thickness of the leaflet; Then the pericardial sheet 1 together with the die into the basket 2, put the basket 2 into the liquid nitrogen tank 3 to freeze. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap