Method for preparing composite chitosan nanogel immobilized multi-layer capsules

A nanogel and multi-layer capsule technology, which is applied in the direction of microcapsule preparation, capsule delivery, microsphere preparation, etc., can solve the problems of reducing the clinical applicability of nanogel, adhesion and precipitation of nanogel, and reducing the efficiency of drug delivery, etc. Achieve the effects of good economic development potential, convenient operation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

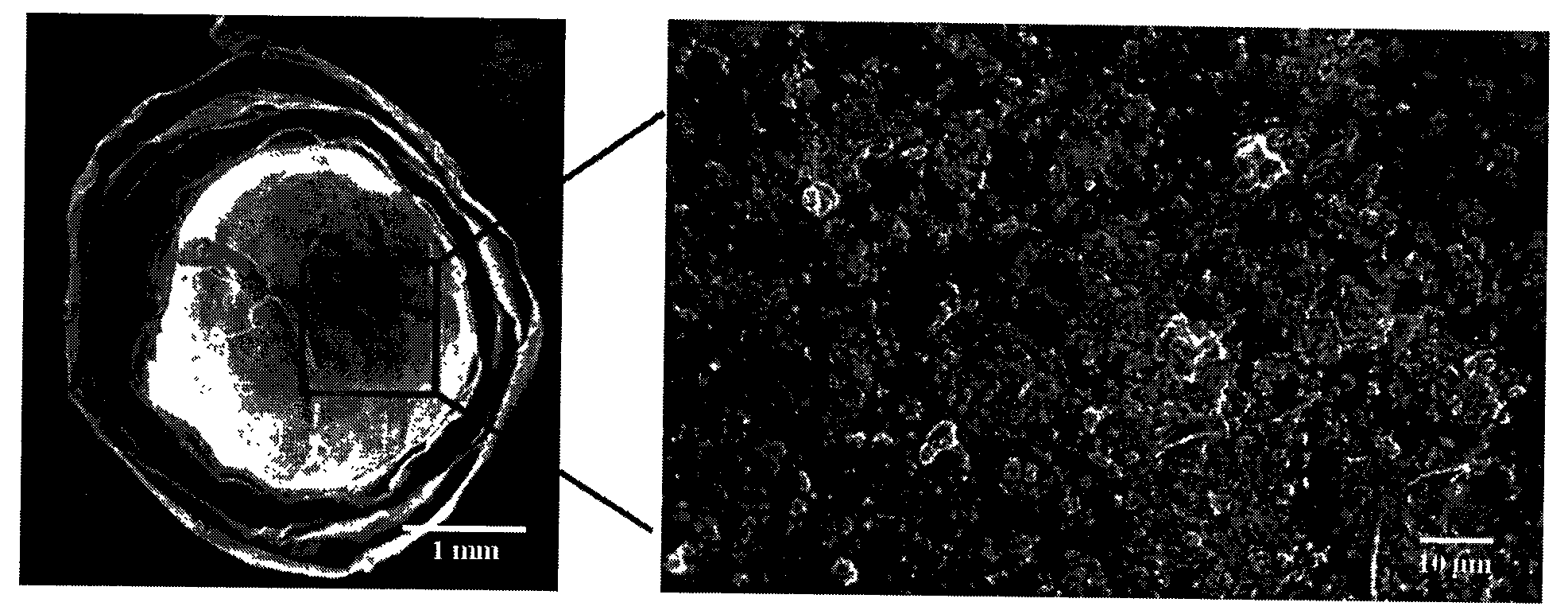

Image

Examples

Embodiment 1

[0017] 10mL, 0.25% (w / v) chitosan-carboxymethyl chitosan nanogel was added to 10mL, 0.5% (w / v) sodium alginate solution, 90W ultrasonic for 5 minutes, the mixed solution Add it into 1% calcium chloride solution (w / V) under 5Kv high-voltage electric field, and solidify for 30 minutes. Rinse with distilled water 3 times to obtain core capsules. Immerse the core capsule in 0.5% (w / v) sodium alginate solution, let it stand for 5 minutes, filter off the excess liquid, put the rubber ball into the mixture of 0.5mL Tween-80 and 200mL liquid paraffin, 500 rpm Stir for 10 minutes per minute, add 50 mL of 1% (w / v) calcium chloride solution, continue stirring at 500 rpm for 30 minutes, rinse with distilled water for 3 times to obtain coated capsules, freeze-dry to obtain a layer of capsules By this product.

Embodiment 2

[0019] 15mL, 0.3% (w / v) chitosan-carboxymethyl chitosan nanogel was added to 15mL, 1% (w / v) sodium alginate solution, 90W ultrasonic 8 minutes, mixed solution in Add it into 2% (w / v) calcium chloride solution under 8Kv high-voltage electric field, and solidify for 30 minutes. Rinse with distilled water 3 times to obtain core capsules. Immerse the core capsule in 1% (w / v) sodium alginate solution, let it stand for 5 minutes, filter off the excess liquid, put the rubber ball into the mixture of 1mL Tween-80 and 200mL liquid paraffin, 500 rpm Stir for 10 minutes, add 50 mL of 2% (w / v) barium chloride solution, continue stirring at 500 rpm for 30 minutes, rinse with distilled water for 3 times to obtain coated capsules, repeat coating 5 times, freeze-dry, that is 5-layer coated product is available.

Embodiment 3

[0021] 10mL, 0.2% (w / v) chitosan-carboxymethyl chitosan nanogel was added to 10mL, 2% (w / v) sodium alginate solution, 90W ultrasonic 10 minutes, the mixed solution Add it into 3% calcium chloride solution under 10Kv high-voltage electric field, and solidify for 30 minutes. Rinse with distilled water 3 times to obtain core capsules. Submerge the core capsule in 1% (w / v) sodium alginate solution, let it stand for 5 minutes, filter off the excess liquid, put the rubber ball into the mixture of 0.8mL Span-80 and 200mL liquid paraffin, 500 Stir for 10 minutes at rpm, add 50 mL of 3% (w / v) calcium chloride solution, continue stirring at 500 rpm for 30 minutes, rinse with distilled water 3 times to obtain coated capsules, repeat coating 15 times, freeze-dry , You can get 15 layers of coated products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com