Forming process for annular carbon fiber composite material pull rod

A composite material and molding process technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of high porosity, poor surface quality of parts, poor working environment, etc., and achieve good low temperature resistance and bearing capacity. Strong, low porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

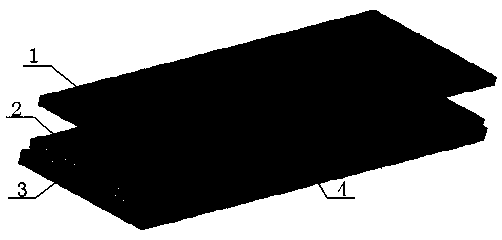

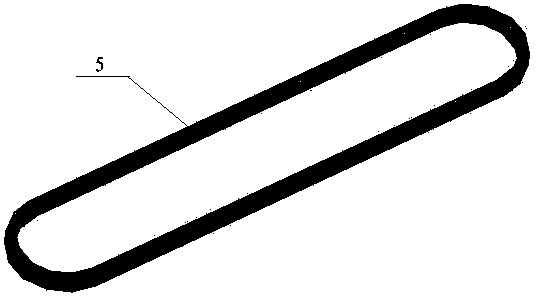

[0032] A carbon fiber composite annular tie rod is prepared through the following steps:

[0033] a. Prepare unidirectional carbon fiber prepreg tape, and cut the unidirectional prepreg tape according to actual needs

[0034] The width of the prepreg tape is determined by the size and compression of the ring tie rod. Generally, the compression amount should be controlled between 12% and 20%. Taking a ring tie rod with a width of 15mm as an example, a prepreg tape with a glue content of 35% is used. The width should be controlled between 17~18.5mm. The length of the prepreg tape is calculated according to the relevant parameters such as the single layer thickness of the prepreg material, the thickness of the ring tie rod, and the volume.

[0035] b. Apply a release agent on the surface of the mandrel, the optional release agents are: oleic acid, paraffin wax, stearic acid, silicone grease release agent, silicone oil release agent, zinc stearate, silicone grease, silicone ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com