Treatment method of acid dye mother liquor wastewater

A technology of acid dyes and treatment methods, which is applied in the textile industry wastewater treatment, water/sewage treatment, adsorbed water/sewage treatment and other directions, can solve problems such as inability to meet requirements, and achieve the effect of saving treatment costs, simple operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

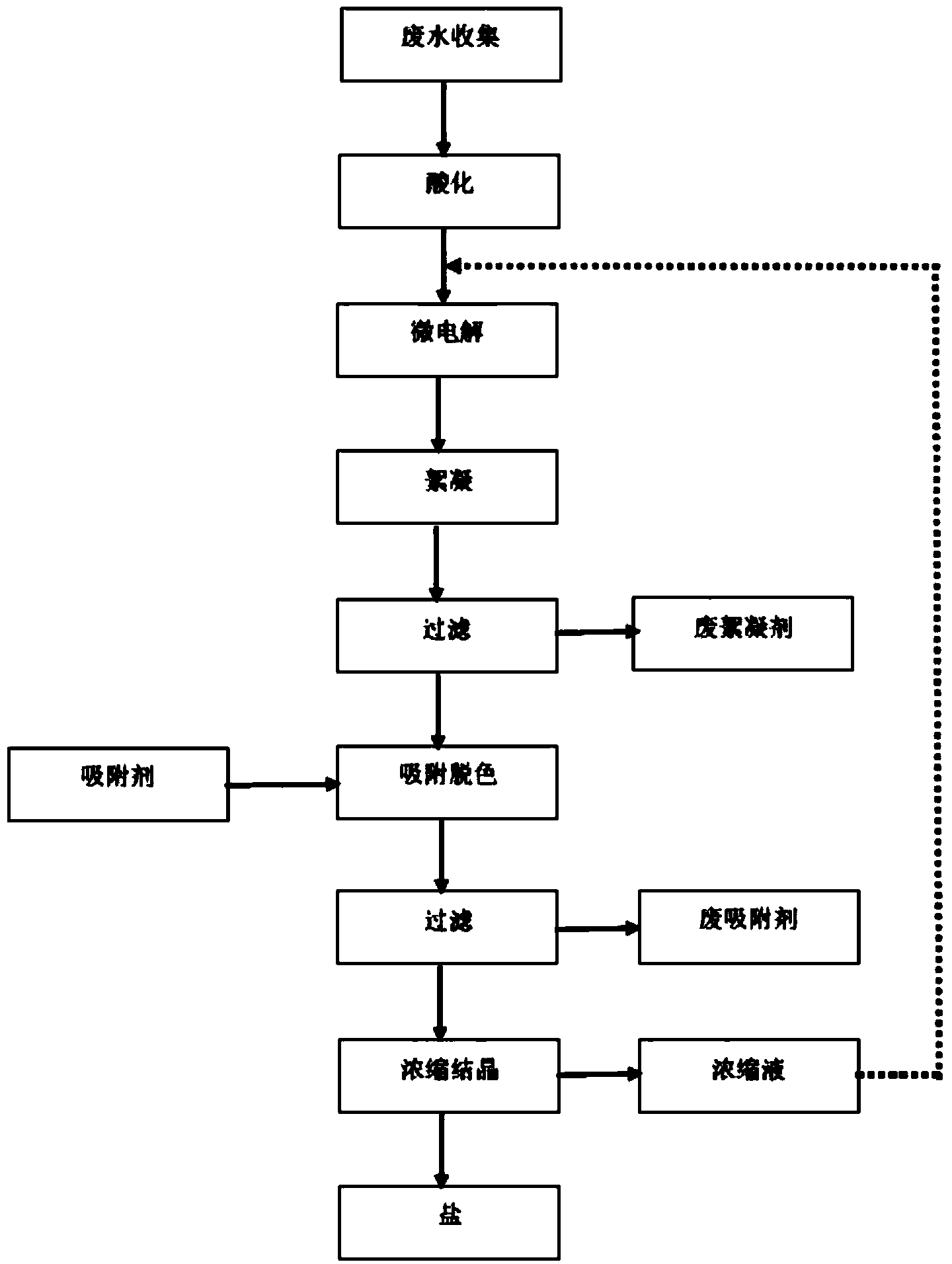

[0030] A kind of treatment method of acid dye mother liquor waste water, its treatment method comprises the following steps:

[0031] (1) Collect and store acid dye mother liquor wastewater; (2) Use dilute sulfuric acid or ammonia water to adjust the pH of the wastewater collected in step (1) to 5, and pour the wastewater into the micro-electrolytic cell; (3) Add weight to the wastewater The percentage is 4% iron powder and 3‰ activated carbon powder, and the waste water is stirred for 4 hours with a stirring machine, and the pH is monitored online during the stirring process to keep the system acidic; the waste water after 4 hours of micro-electrolysis reaction is passed through a filter press Filtrate, the filtrate COD is about 5800mg / L, and the COD removal rate is about 55%; (4) Add liquid caustic soda to the filtrate at a constant speed until the pH of the solution reaches 10 and stir at a medium speed for 0.5 hours. After confirming that the pH is > 7, continue stirring fo...

Embodiment 2

[0033] A kind of treatment method of acid dye mother liquor waste water, its treatment method comprises the following steps:

[0034] (1) Collect and store acid dye mother liquid wastewater; (2) Put dilute sulfuric acid or ammonia water into the wastewater collected in step (1), adjust the pH of the wastewater to 5 and put it into the micro-electrolytic pool; (3) Put the wastewater into the wastewater Add 1% iron powder and 1‰ activated carbon powder and stir to make the waste water fully contact with the micro-electrolysis reagent for 4 hours, and monitor the pH online during the stirring process to keep the system acidic; the solution is then filtered through a filter press, The filtrate COD is about 5800mg / L, and the COD removal rate is about 55%; (4) Add 0.5% ferrous sulfate and 0.001% polyacrylamide to the filtrate and adjust the pH of the solution to 9 for flocculation. After rapid stirring for 0.5 hours, the pH of the solution was measured to be 6, and liquid caustic so...

Embodiment 3

[0036] A kind of treatment method of acid dye mother liquor waste water, its treatment method comprises the following steps:

[0037] (1) Collect and store acid dye mother liquor wastewater; (2) Put dilute sulfuric acid or ammonia water into the wastewater collected in step (1), adjust the pH of the wastewater to 3 and put it into the micro-electrolytic cell; (3) Add to the solution The weight percentage is 4% iron powder and 3‰ activated carbon powder and the liquid is stirred for 4 hours of iron-carbon micro-electrolysis. Monitor the pH online during the stirring process to keep the system acidic; the solution is then filtered through the sub-filter, and the COD of the filtrate is measured to be about 4240mg / L, and the COD removal rate is about 71%; (4) Add 3% by weight to the filtrate ferrous sulfate, adjust the pH of the solution to 10, stir for 2 hours and filter; (5) add 0.03% activated carbon to the filtrate and stir for 0.5 hours, the filtrate COD obtained by filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com