Ultraviolet curing alkali cleaning resin and its preparation method and the preparation method of matte ink

A matte ink and ultraviolet light technology, applied in the field of ink material manufacturing, can solve the problems of high viscosity of epoxy acrylate, affecting construction and leveling, and single color, etc., and achieve good adhesion, fast alkali dissolution speed, and low odor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a method for preparing the above-mentioned ultraviolet curing alkali cleaning resin, including:

[0028] Get each component by ultraviolet curing alkali cleaning resin formula of the present invention;

[0029] Prepared by the following steps:

[0030] 1) Mixing of raw materials: mixing the acid anhydride and hydroxyacrylate to form a mixture;

[0031] 2) Pre-reaction: add the mixture obtained in step 1) into the reaction kettle and gradually raise the temperature to 95°C to 105°C, and fully stir to dissolve the mixture;

[0032] 3) Adding a polymerization inhibitor and a catalyst: adding the polymerization inhibitor and a catalyst to the reaction kettle after the mixture is dissolved, and reacting at a temperature of 95-100° C. under normal pressure and constant temperature for 1 hour under stirring;

[0033] 4) Heating reaction: After the constant temperature reaction, gradually increase the temperature to 105°C-...

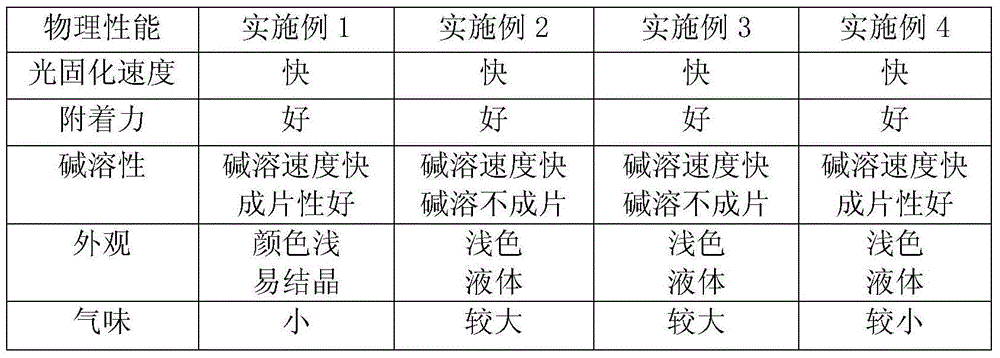

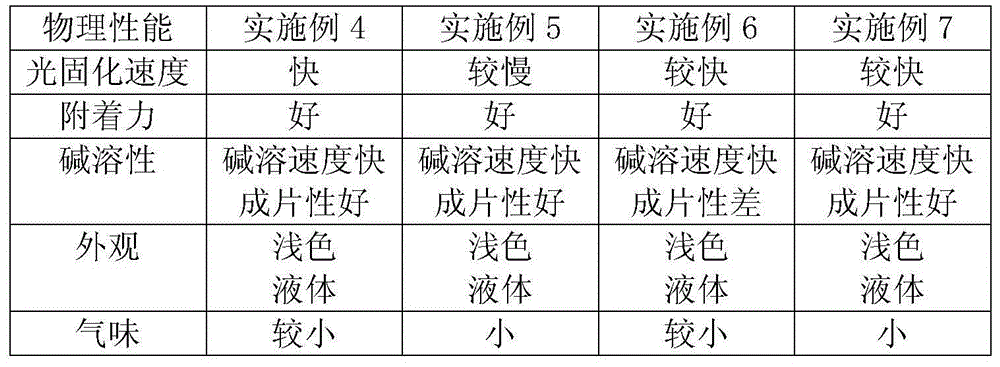

Embodiment 1

[0039] This embodiment provides a UV-curable alkali-washed resin, which is prepared by the following steps:

[0040] Take 0.5mol of phthalic anhydride, 0.5mol of hexahydrophthalic anhydride, and 1mol of hydroxyethyl acrylate to form a mixture;

[0041] Add the mixture into the reaction kettle, and gradually raise the temperature to 95°C to 105°C under stirring to completely dissolve the reactants of the mixture;

[0042] After the mixture is completely dissolved, add 0.1% to 0.2% of p-hydroxyanisole, 0.1% of the total mass of the mixture, and 0.1% of triphenylphosphine to the reactor to adjust the temperature of the reactor. Temperature to 100°C, under stirring state, react at normal pressure and constant temperature for 1h;

[0043] Continue to heat up to 105°C to 110°C, and react for 4 hours at normal pressure and constant temperature;

[0044] After the reaction is complete, take a small amount of sample to measure its acid value, and control the acid value within the ran...

Embodiment 2

[0046] This embodiment provides a UV-curable alkali-washed resin, which is prepared by the following steps:

[0047] Take 0.5 mol of phthalic anhydride, 0.5 mol of methyl hexahydrophthalic anhydride, and 1 mol of hydroxyethyl acrylate to form a mixture;

[0048] Add the mixture into the reaction kettle, and gradually raise the temperature to 95°C to 105°C under stirring to completely dissolve the mixture;

[0049] After the mixture is completely dissolved, add 0.1% to 0.2% of p-hydroxyanisole, 0.1% of the total mass of the mixture, and 0.1% of triphenylphosphine to the reactor to adjust the temperature of the reactor. Temperature to 100°C, under stirring state, react at normal pressure and constant temperature for 1h;

[0050] Continue to heat up to 105 ° C ~ 110 ° C, and then react at normal pressure and constant temperature for 4 hours;

[0051] After the reaction is complete, take a small amount of sample to measure its acid value, and control the acid value within the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com