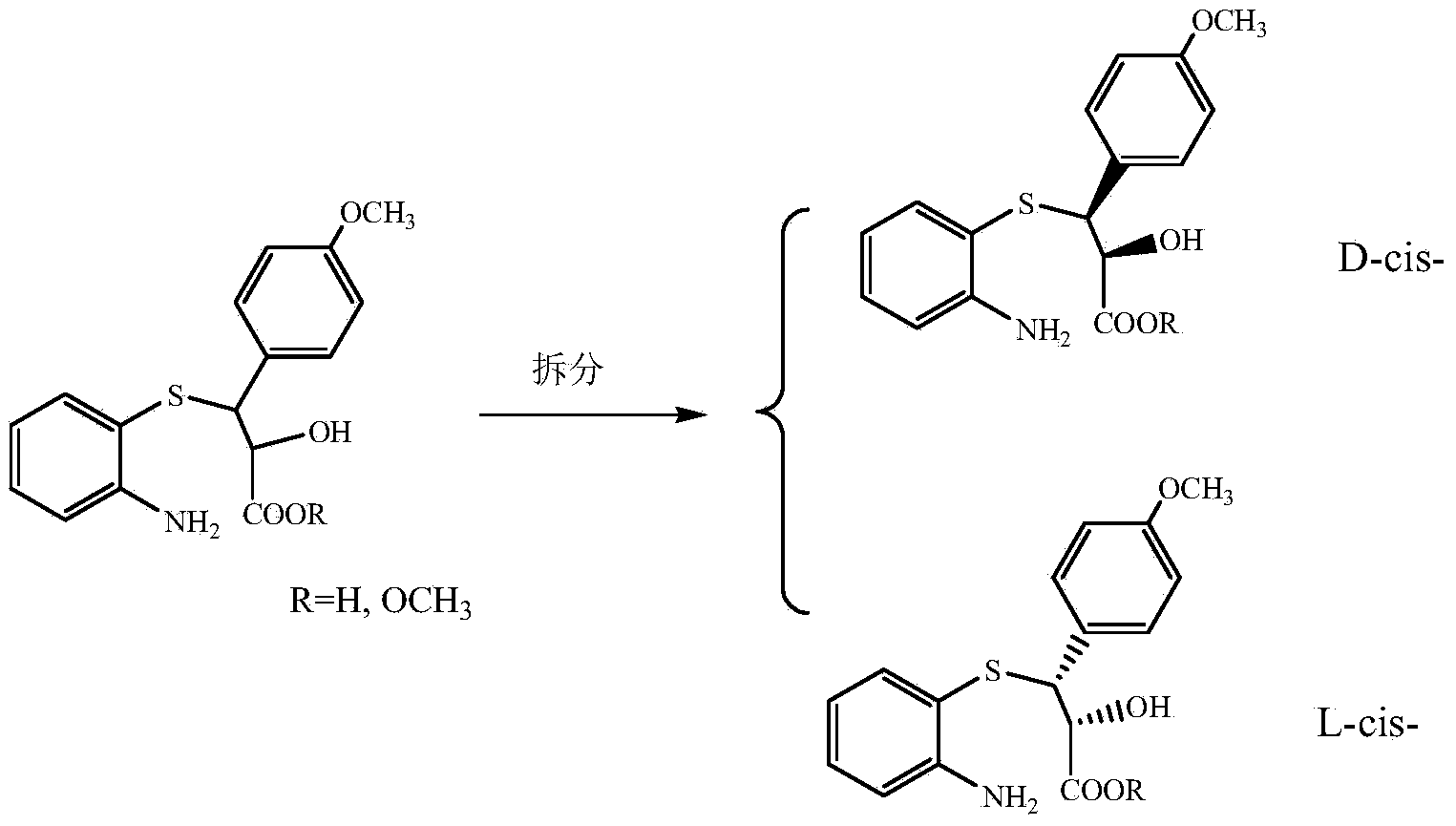

Process for recycling L-cis-lactam as diltiazem intermediate by-product

A technology of l-cis- and diltiazem, applied in organic chemistry and other directions, can solve problems such as route extension and long reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

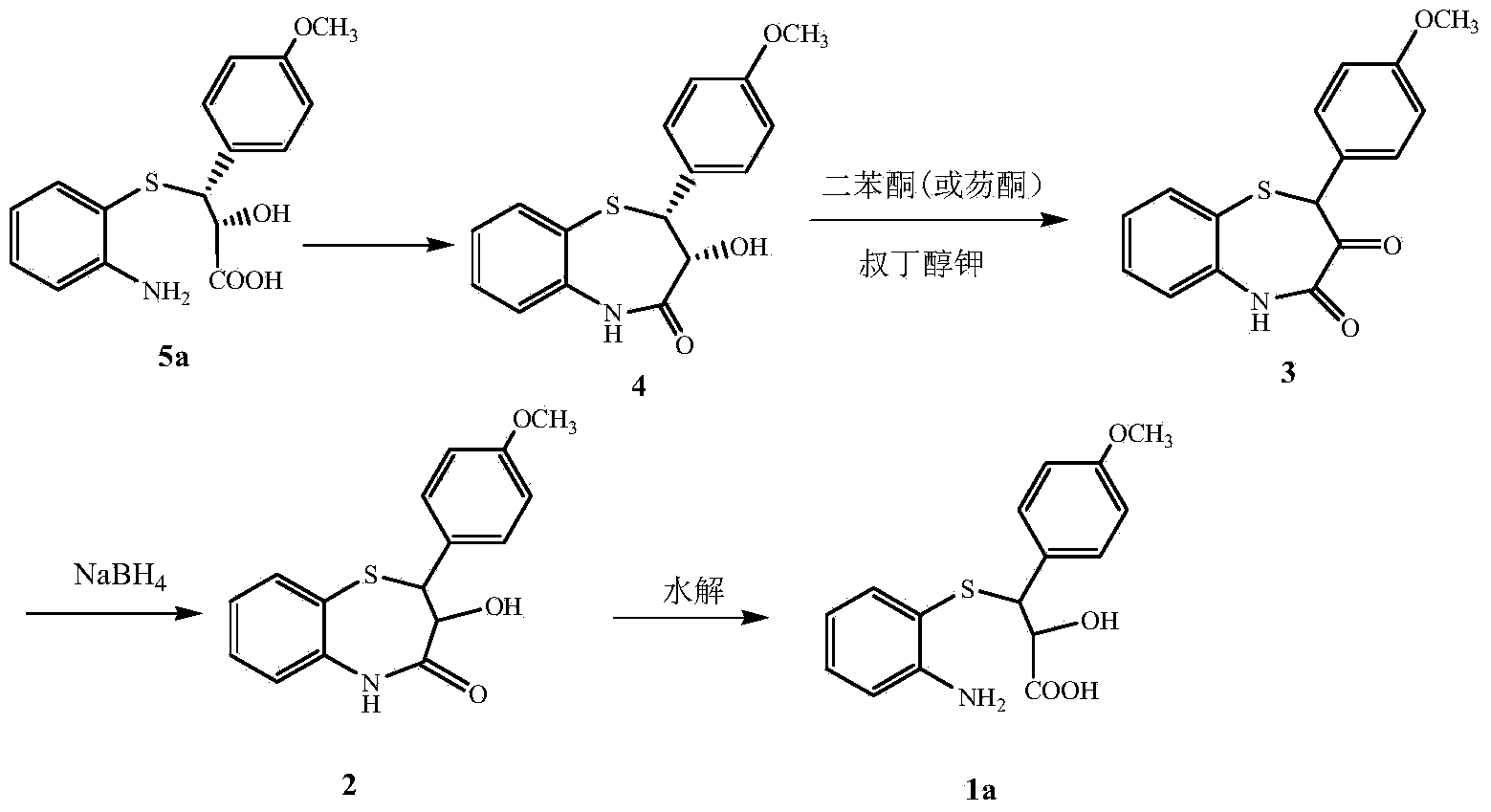

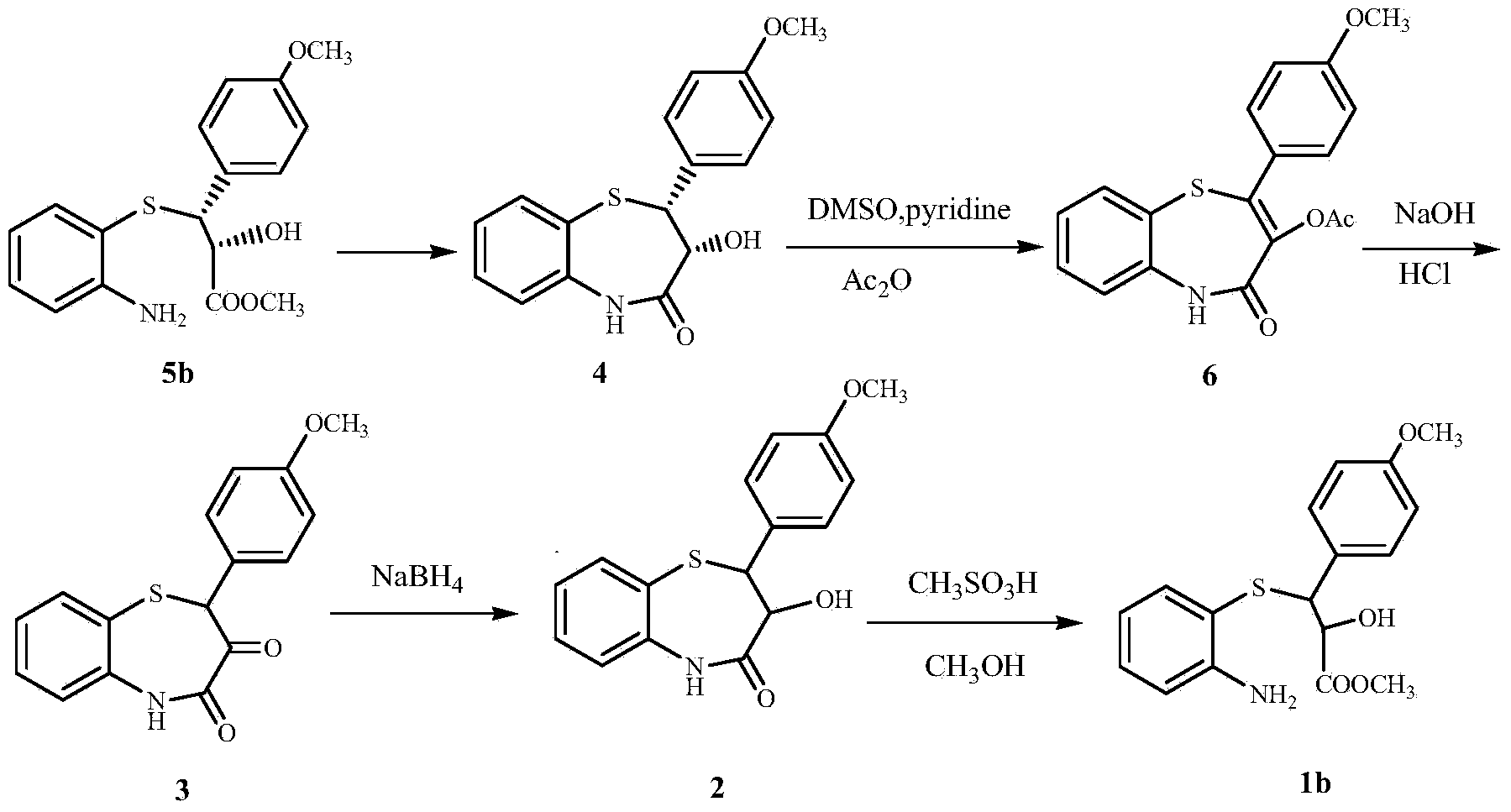

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 5g (0.017mol) of L-cis-lactam (4) in 25ml of DMSO (containing 10% water), then add 5.35g (0.019mol) of IBX, and stir at 80°C for 6h. After the reaction is complete, pour into 200ml of cold water, stir for 1 hour, and then filter to collect the filter cake. The filter cake was washed with ethyl acetate, the mother liquor was washed with water, dried, and concentrated under reduced pressure to obtain 2-(4-methoxyphenyl)-1,5-benzothiazepine-3,4-(2H,5H)- Diketone (3), 4.5g, yield 90%, mp161-163°C, e.e.% is 0. The filter cake was dried and recovered to obtain IBA, 4.49g, with a recovery rate of 89%.

Embodiment 2

[0022] Dissolve 5g (0.017mol) of L-cis-lactam (4) in 25ml of DMSO (containing 5% water), then add 9.33g (0.034mol) of IBX, and stir at 5°C for 10h. After the reaction is complete, pour into 200ml of cold water, stir for 1 hour, and then filter to collect the filter cake. The filter cake was washed with ethyl acetate, the mother liquor was washed with water, dried, and concentrated under reduced pressure to obtain 2-(4-methoxyphenyl)-1,5-benzothiazepine-3,4-(2H,5H)- Diketone (3), 4.62g, yield 92%, mp162-163°C, e.e.% is 0. The filter cake was dried and recovered to obtain IBA, 7.75g, with a recovery rate of 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com