Photosensitive water-soluble coating and preparation method thereof

A water-soluble coating and photosensitive technology, applied in the coating field, can solve problems such as pollution of the environment and molecular weight limitation, and achieve the effects of overcoming pollution, simple preparation method and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

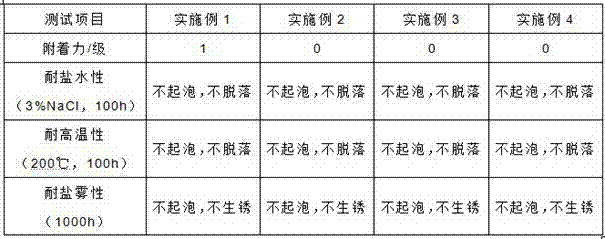

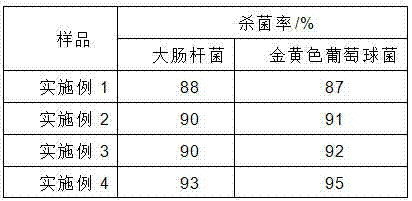

Examples

Embodiment 1

[0014] A photosensitive water-soluble paint, comprising the following raw materials in parts by weight: 100 parts of phenolic epoxy acrylic photosensitive resin, 2 parts of photoinitiator EDAB, 1 part of isopropyl thioxanthone, ethoxylated trihydroxy 18 parts of methylpropane triacrylate, 3 parts of ammonia water, 2 parts of thickener TT-935, 1 part of zinc stearate, 0.5 parts of nano-titanium dioxide, 5 parts of acetone, and 30 parts of water.

[0015] The preparation method of the photosensitive water-soluble paint in this embodiment is obtained by mixing, stirring and removing impurities by physical methods according to the above-mentioned raw material ratio.

Embodiment 2

[0017] A photosensitive water-soluble paint, comprising the following raw materials in parts by weight: 120 parts of phenolic epoxy acrylic photosensitive resin, 5 parts of photoinitiator EDAB, 2 parts of isopropyl thioxanthone, ethoxylated trihydroxy 25 parts of methyl propane triacrylate, 6 parts of ammonia water, 5 parts of thickener TT-935, 3 parts of zinc stearate, 2 parts of nano-titanium dioxide, 8 parts of acetone, and 50 parts of water.

[0018] The preparation method of the photosensitive water-soluble paint in this embodiment is obtained by mixing, stirring and removing impurities by physical methods according to the above-mentioned raw material ratio.

[0019]

Embodiment 3

[0021] A photosensitive water-soluble paint, comprising the following raw materials in parts by weight: 110 parts of novolac epoxy acrylic photosensitive resin, 4 parts of photoinitiator EDAB, 1.5 parts of isopropyl thioxanthone, ethoxylated trihydroxy 22 parts of methyl propane triacrylate, 4 parts of ammonia water, 3 parts of thickener TT-935, 1.8 parts of zinc stearate, 1 part of nano titanium dioxide, 6 parts of acetone, 36 parts of water.

[0022] The preparation method of the photosensitive water-soluble paint in this embodiment is obtained by mixing, stirring and removing impurities by physical methods according to the above-mentioned raw material ratio.

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com