A bacterial-enzyme combination preparation containing Bacillus subtilis strain xp and its application in accelerating starch degradation in tobacco flakes

A combination technology of Bacillus subtilis and bacterial enzymes, applied in the field of microorganisms, can solve the problems of reagent consumption error, unsatisfactory starch effect, large error, etc., and achieve the effect of improving the grade of flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

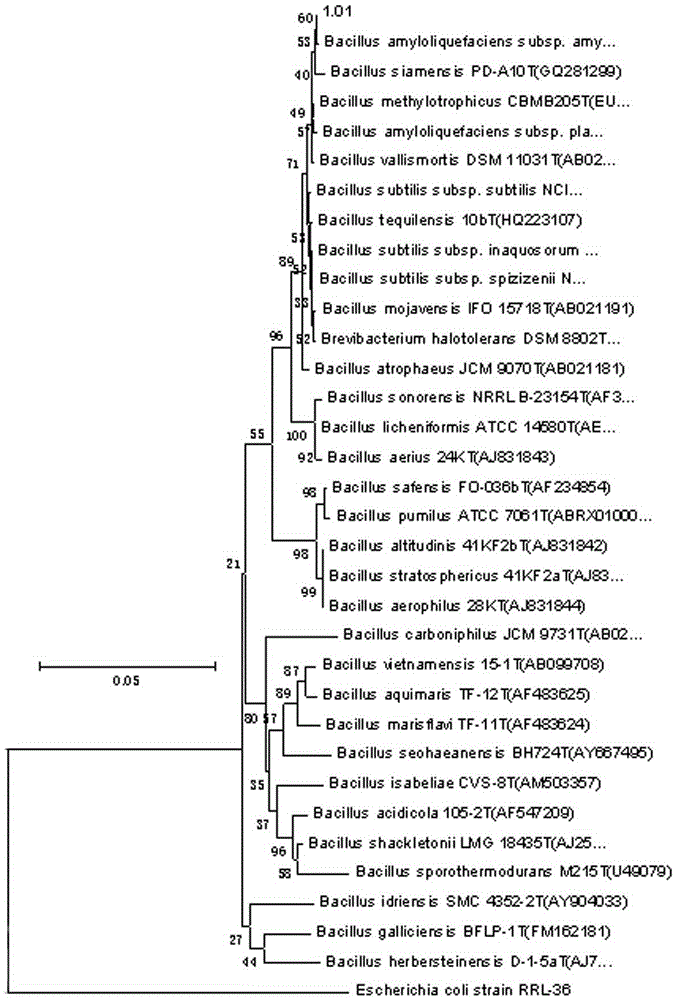

Method used

Image

Examples

Embodiment 1

[0038] Preparation of microorganism-enzyme preparation of the present invention and method for measuring enzyme activity

[0039] 1. Preparation of microbial preparations

[0040] 1) Slant culture: suspend the strain xp in 0.5ml LB liquid medium, then pick up the bacterial liquid with an inoculation loop and culture it on a slant at 37°C for 14 hours;

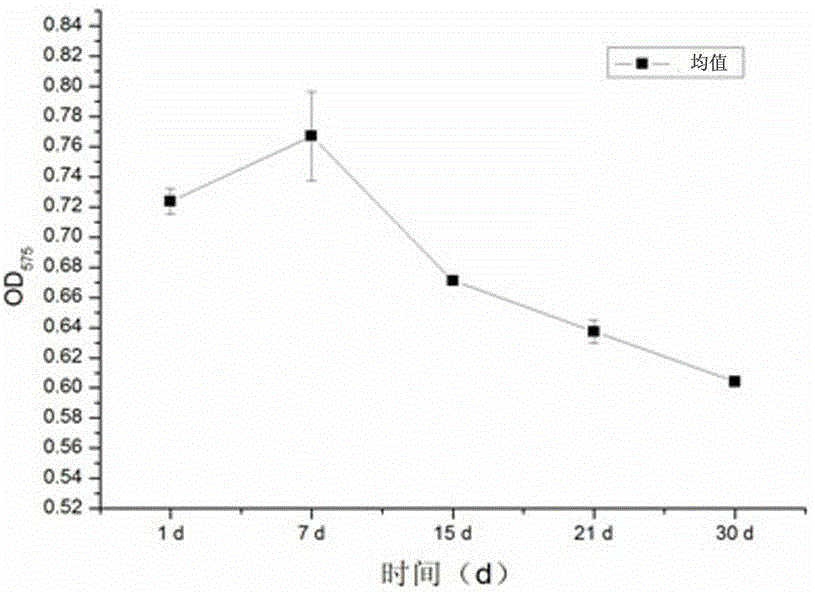

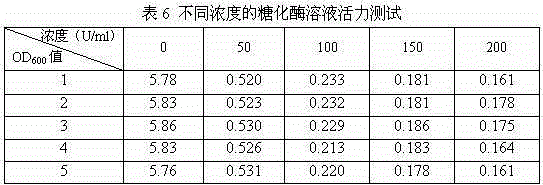

[0041] 2) Seed culture: Take the bacteria obtained in step 1) and inoculate a single colony with an inoculation loop in a 300ml Erlenmeyer flask containing 100ml LB liquid medium under aseptic conditions, and culture it on a shaker at 37°C until OD 600 The value is 5.0 (about 10h, the rotation speed is 200rpm), and the seed solution is obtained. Collect the seed solution, put it into a 250ml bacterial solution collection bottle, and centrifuge at 4°C, the centrifugation condition used is 8000rpm, 20min. The supernatant was taken for enzyme activity assay. The enzyme activity was determined by the starch-iodine chromogenic me...

Embodiment 2

[0060] A bacterium-enzyme joint preparation containing bacillus subtilis strain xp, which is prepared by the following steps:

[0061] 1) Slant culture: suspend the strain xp in LB liquid medium, then pick up the bacterial liquid with an inoculation loop and culture it on a slant at 37°C for 14 hours;

[0062] 2) Seed culture: Take the bacteria obtained in step 1) and pick a single colony with an inoculation loop under sterile conditions to inoculate in LB liquid culture based on a shaker at 37°C to OD 600 The value is 5.0 (about 10h), and the seed solution is obtained;

[0063] 3) Mix the seed liquid with amylase, cellulase and glucoamylase in a volume ratio of 1:1:1:1. The enzyme activity concentrations of the amylase, cellulase and glucoamylase are 8U / ml, 800U / ml and 100U / ml respectively.

[0064] At a temperature of 30°C and a humidity of 60%, 100ml of the above bacteria-enzyme joint preparation was evenly sprayed on the surface of 500g of tobacco flakes, and samples wer...

Embodiment 3

[0069] A bacterium-enzyme joint preparation containing bacillus subtilis strain xp, which is prepared by the following steps:

[0070] 1) Slant culture: suspend the strain xp in LB liquid medium, then pick up the bacterial liquid with an inoculation loop and culture it on a slant at 37°C for 14 hours;

[0071] 2) Seed culture: Take the bacteria obtained in step 1) and pick a single colony with an inoculation loop under sterile conditions to inoculate in LB liquid culture based on a shaker at 37°C to OD 600 The value is 5.0 (about 10h), and the seed solution is obtained;

[0072] 3) Mix the seed liquid with amylase, cellulase and glucoamylase in a volume ratio of 1:1:1:1. The enzyme activity concentrations of the amylase, cellulase and glucoamylase are 8U / ml, 800U / ml and 100U / ml respectively.

[0073] At a temperature of 30°C, 100ml of the above bacteria-enzyme joint preparation was applied to 10L of the water-soluble extract solution (pH value of natural, about 6.0) of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com