Method for spraying hypersonic flame on surface of intermediate/high-temperature furnace roller

A supersonic flame, medium and high temperature technology, applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of reduced service life, short working time, and low surface hardness of furnace rollers, so as to prolong the service life , Improve wear resistance, high bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment includes the following steps:

[0045] The supersonic flame spraying method on the surface of medium and high temperature furnace rollers is carried out according to the following steps:

[0046] 1) Derusting the surface of the furnace roller until the surface of the furnace roller is smooth;

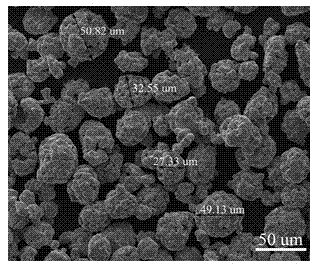

[0047] 2) The surface of the furnace roller is sandblasted to achieve a certain roughness. The roughness is determined according to the nature of the coating and the requirements of the user;

[0048] 2. Sealing agent configuration

[0049] 1) The composition of the sealing agent: Zirconium silicate alkoxide is used as the sealing agent, and PEG200 (polyethylene glycol), purified water, zirconium silicate and ethanol are mixed evenly according to the weight percentage, that is, PEG200: 30%, pure Water 20%, zirconium silicate: 15%, ethanol: 35%;

[0050] 2) Preparation conditions

[0051] Under normal temperature and pressure, add zirconium silicate to an ordin...

Embodiment 2

[0071] Processed with the method of Example 1, the spraying process parameters are listed in Table 1, and the test results are listed in Table 2.

Embodiment 3

[0073] Processed with the method of Example 1, the spraying process parameters are listed in Table 1, and the test results are listed in Table 2.

[0074] Table 1 embodiment process parameters

[0075] unit Example 1 Example 2 Example 3 oxygen flow L / m 838 858 878 fuel flow L / h 22.0 22.5 23.0 Powder feeding speed g / min 25.0×2 27.5×2 30.0×2 Spray distance mm 320 340 360 Coatings 22 20 18 PEG200 % 30 30 30 pure water % 20 25 15 Zirconium silicate % 15 20 20 ethanol % 35 25 35 Natural drying time, curing temperature and time 2h, 200℃, keep warm for 2.5h 3h, 250℃, keep warm for 2h 4h, 300℃, keep warm for 2h

[0076] Table 2 Test results

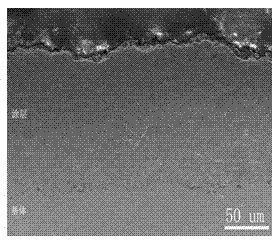

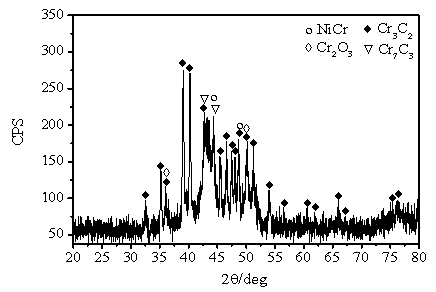

[0077] unit Example 1 Example 2 Example 3 Coating thickness mm 0.098 0.091 0.087 Bond strength MPa 75 82 78 Porosity % 0.58 0.55 0.64 Surface hardness HV 1 884.6 912....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com