A kind of preparation method of surface strengthened fe-w alloy

A surface strengthening and alloying technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of long carburizing time and large hardness gradient of carburizing layer, so as to reduce carburizing energy consumption, The effect of structure refinement and shortening carburizing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The mass percentage of Fe-W alloy composition is: W5.5%, Fe94.5%. The Fe-W alloy sample was made into a 20×20×50 sample with a wire cutting machine, polished with 240#, 800# and 1200# water sandpaper in turn, cleaned with ultrasonic waves in distilled water, and then dried.

[0021] Dissolve lanthanum chloride in methanol to make a mixed rare earth infiltrator, and the ratio of lanthanum chloride to methanol is 3 grams: 1000ml. Choose isopropanol as carburizing agent.

[0022] The carburizing temperature is 860°C, the carburizing time is 4 hours, and the carbon potential of the furnace gas during the carburizing stage is kept at Cp=1.15%±0.05%. After carburizing, the workpiece is water quenched.

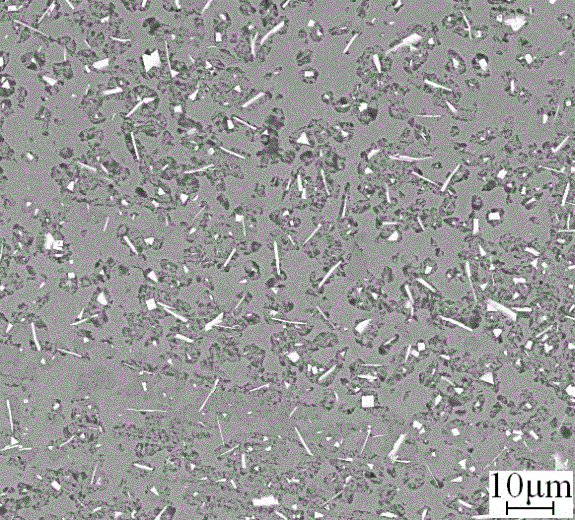

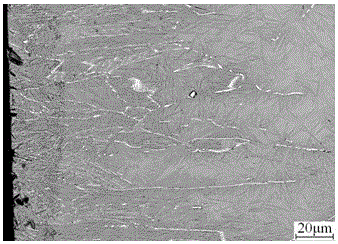

[0023] figure 1 with figure 2 The scanning electron micrographs of the surface and longitudinal section of the alloy carburized layer prepared in this embodiment are respectively.

[0024] In this example, the rare earth infiltration process can refer to http: / / wenku.bai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com