Method for preparing superlattice nanowire array assembled by tellurium-lead telluride nanocrystals

A nanowire array and lead telluride technology, applied in chemical instruments and methods, nanotechnology, single crystal growth, etc., to achieve composition and structure control, simple preparation method, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

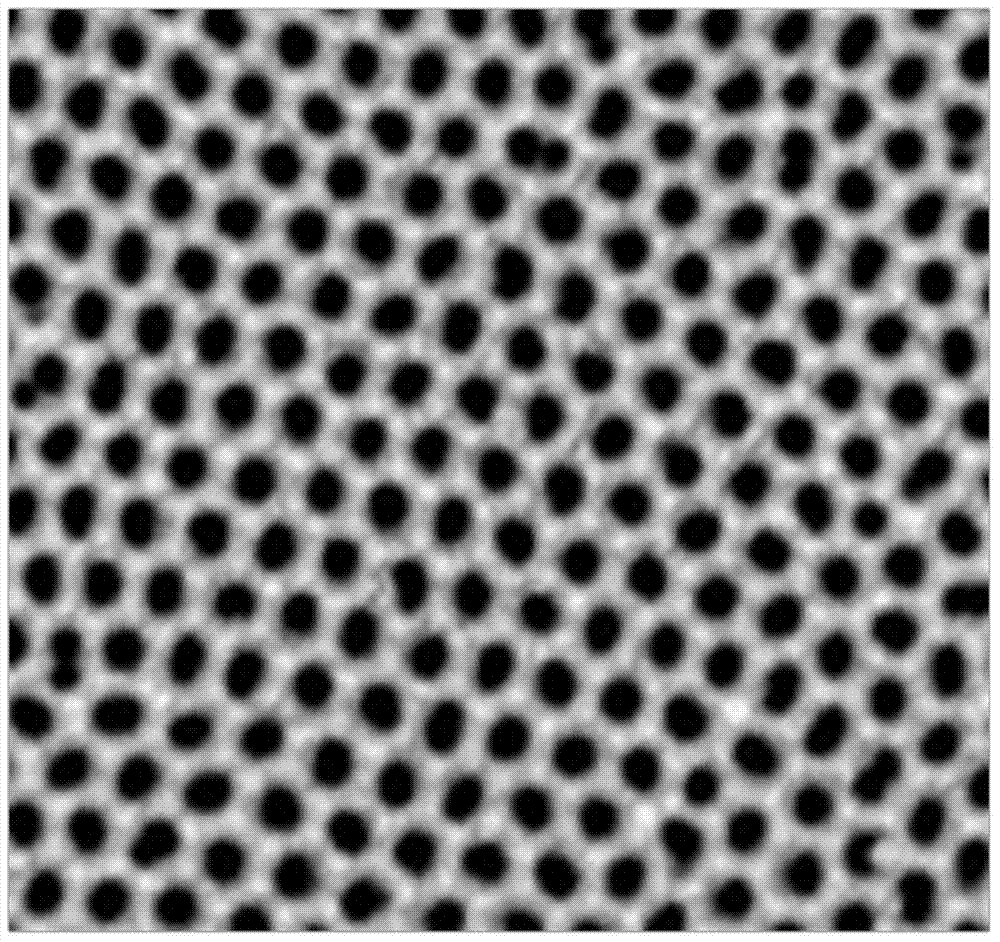

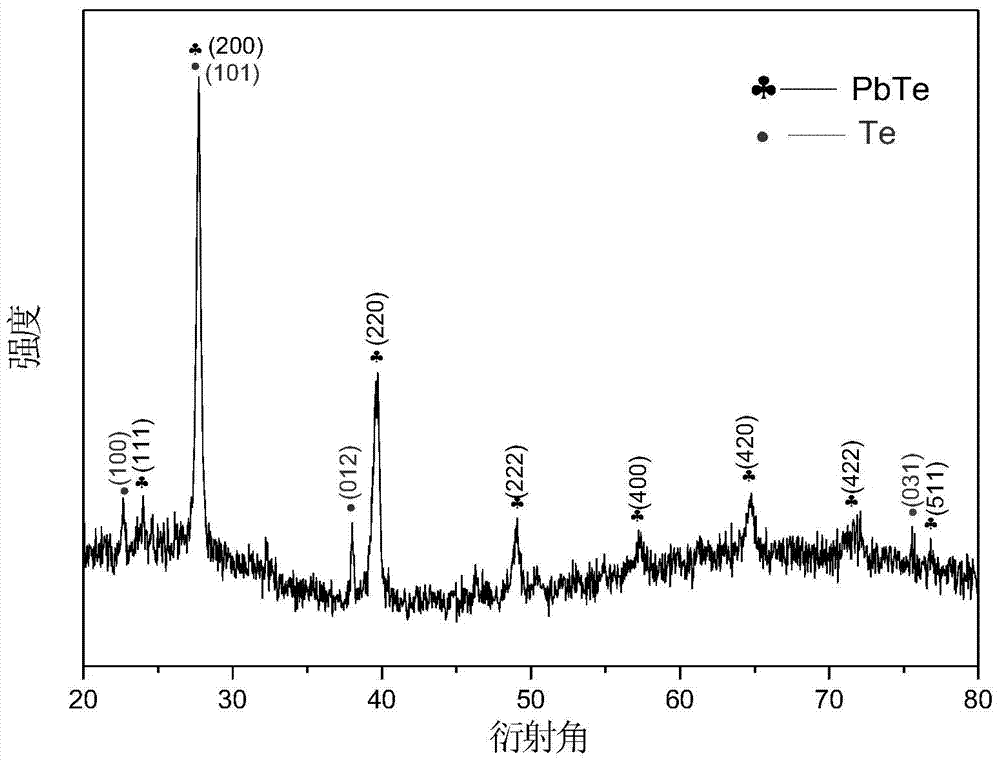

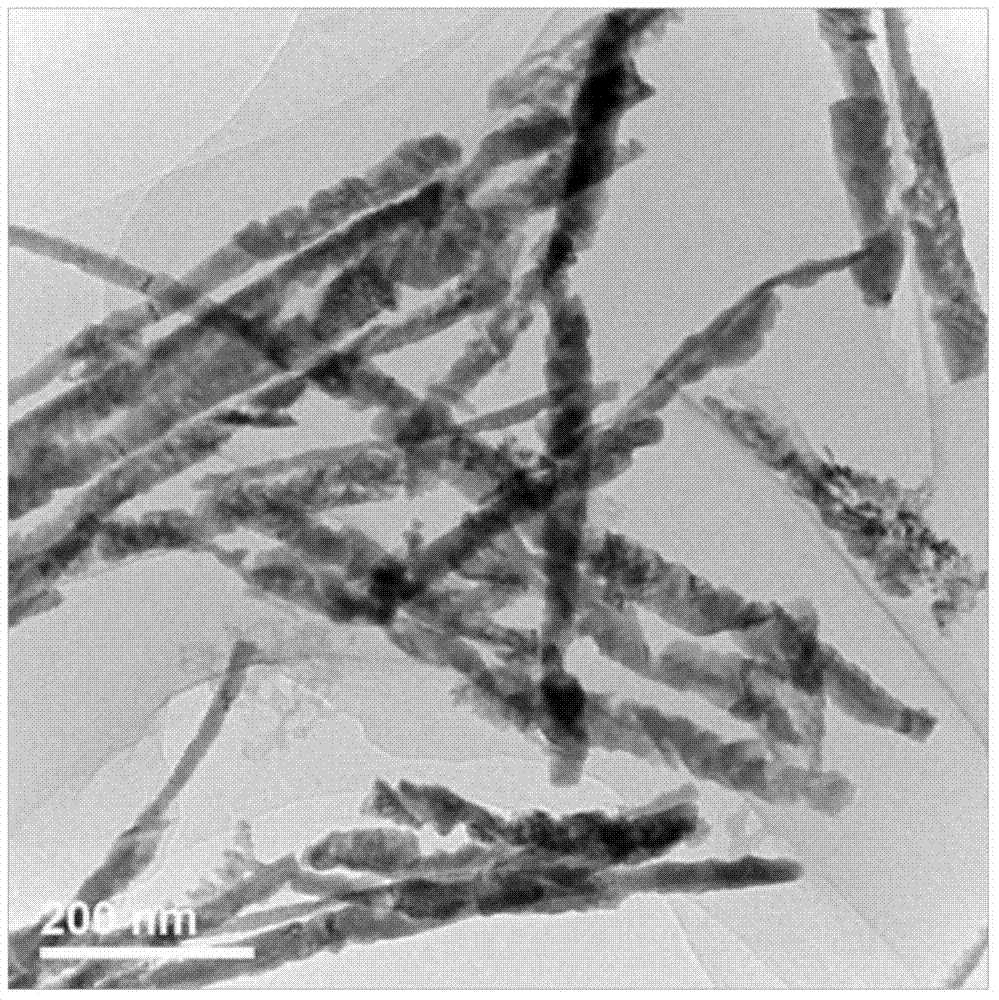

[0021] A PAA template is prepared by a secondary anodic oxidation method, and a 100nm-200nm gold film is sputtered and evaporated on its back as an electrode. Then prepare the electrodeposition solution, the solution is made of TeO 2 , Pb(NO 3 ) 2 , tartaric acid, ethanol, HNO 3 Solution composition. Dissolve 3g of tartaric acid in a small amount of deionized water first, then add 5mM TeO 2 , under the condition of constant temperature magnetic stirring at 60℃, add HNO dropwise with a dropper 3 When the solution was clear, add 5mMPb (NO 3 ) 2 , continue to drop HNO with dropper 3 The solution became clear. Add 20ml of ethanol and deionized water to make a 100ml solution, and stir evenly. by dropwise addition of HNO 3 Make the solution pH 1. Using a pulsed electrochemical deposition method, a gold-sprayed PAA template was used as the anode and graphite as the cathode. Before the electrodeposition, in order to make the solution contact with the surface of the PAA tem...

Embodiment 2

[0026] A PAA template is prepared by a secondary anodic oxidation method, and a 100nm-200nm gold film is sputtered and evaporated on its back as an electrode. Then prepare the electrodeposition solution, the solution is made of TeO 2, Pb(NO 3 ) 2 , tartaric acid, ethanol, HNO 3 Solution composition. Dissolve 3g of tartaric acid in a small amount of deionized water first, then add 5mM TeO 2 , under the condition of constant temperature magnetic stirring at 60℃, add HNO dropwise with a dropper 3 When the solution was clear, add 5mMPb (NO 3 ) 2 , continue to drop HNO with dropper 3 The solution became clear. Add 20ml of ethanol and deionized water to prepare a 100ml solution, and stir evenly. by dropwise addition of HNO 3 Make the solution pH 1. Using a pulsed electrochemical deposition method, a gold-sprayed PAA template was used as the anode and graphite as the cathode. Before the electrodeposition, in order to make the solution contact with the surface of the PAA t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com