A super-soft, high-adhesion, high-temperature, flame-retardant, environmentally friendly single-core wire and its preparation method

A high-adhesion, high-temperature-resistant technology, used in circuits, electrical components, insulated cables, etc., can solve the problems of high price, high cost, complex process, etc., and achieve the effect of good softness and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

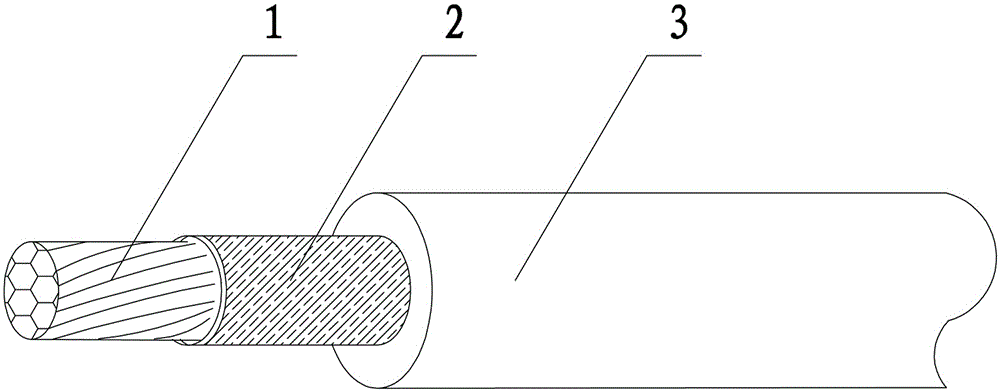

[0021] see figure 1 , the ultra-soft, high-adhesion, high-temperature-resistant, flame-retardant, and environmentally friendly single-core wire of the present invention is composed of an inner conductor 1, a first insulating layer 2, and a second insulating layer 3 in sequence. In this embodiment, the inner conductor adopts a 24AWG wire gauge (cross-sectional area 0.204mm 2 ) Oxygen-free bare copper conductor, the stranded outer diameter is 0.59mm, and the conductor lay length is 18 times the conductor stranded outer diameter. The wire is twisted with oxygen-free copper with low resistance, which meets the requirements of the GB / T3956-2008 "Cable Conductor" standard.

[0022] The first insulating layer is a modified ethylene-acrylic acid copolymer, which is composed of the following materials and parts by weight: ethylene-vinyl acetate 18, polyethylene 15, hydrotalcite 6, flame retardant 9.6, 1010 antioxidant 0.5, Titanate coupling agent 0.5, wax 0.1, white oil 0.4, thickene...

Embodiment 2

[0026] see figure 1 , the super-soft, high-adhesion, high-temperature-resistant, flame-retardant, and environmentally friendly single-core wire of the present invention is composed of an inner conductor 1, a first insulating layer 2, and a second insulating layer 3 in sequence. In this embodiment, the inner conductor adopts a 24AWG wire gauge (cross-sectional area 0.204mm 2 ), twisted by 26 0.10mm tinned copper wires.

[0027] The first insulating layer is a modified ethylene-acrylic acid copolymer, which is composed of the following materials and parts by weight: ethylene-vinyl acetate 50, polyethylene 30, hydrotalcite 25, flame retardant 35, 1010 antioxidant 2, Titanate coupling agent 2, wax 1.5, white oil 2, thickener 2; when preparing, first weigh according to the proportion, mix and stir, refine at 130°C for 20 minutes, pass through 35+65 type double-layer The 35 extruders on the co-extrusion plastic extruder are extruded, and the thickness of the insulating layer is 0....

Embodiment 3

[0031] see figure 1 , the ultra-soft, high-adhesion, high-temperature-resistant, flame-retardant, and environmentally friendly single-core wire of the present invention is composed of an inner conductor 1, a first insulating layer 2, and a second insulating layer 3 in sequence. In this embodiment, the inner conductor adopts a 24AWG wire gauge (cross-sectional area 0.204mm 2 ) Oxygen-free bare copper conductor, the stranded outer diameter is 0.59mm, and the conductor lay length is 18 times the conductor stranded outer diameter. The wire is twisted with oxygen-free copper with low resistance, which meets the requirements of the GB / T3956-2008 "Cable Conductor" standard.

[0032] The first insulating layer is a modified ethylene-acrylic acid copolymer, which is composed of the following materials and parts by weight: ethylene-vinyl acetate 30, polyethylene 25, hydrotalcite 15, flame retardant 25, 1010 antioxidant 1.0, Titanate coupling agent 1.0, wax 0.8, white oil 1.5, thickene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com