Device and method for processing fruit and vegetables containing high anthocyanin content

A technology of fruits, vegetables and raw materials, applied in the fields of application, juice extraction, food science, etc., can solve the problems of slow enzyme inactivation, destruction of easily oxidized components, and reduction of anthocyanin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

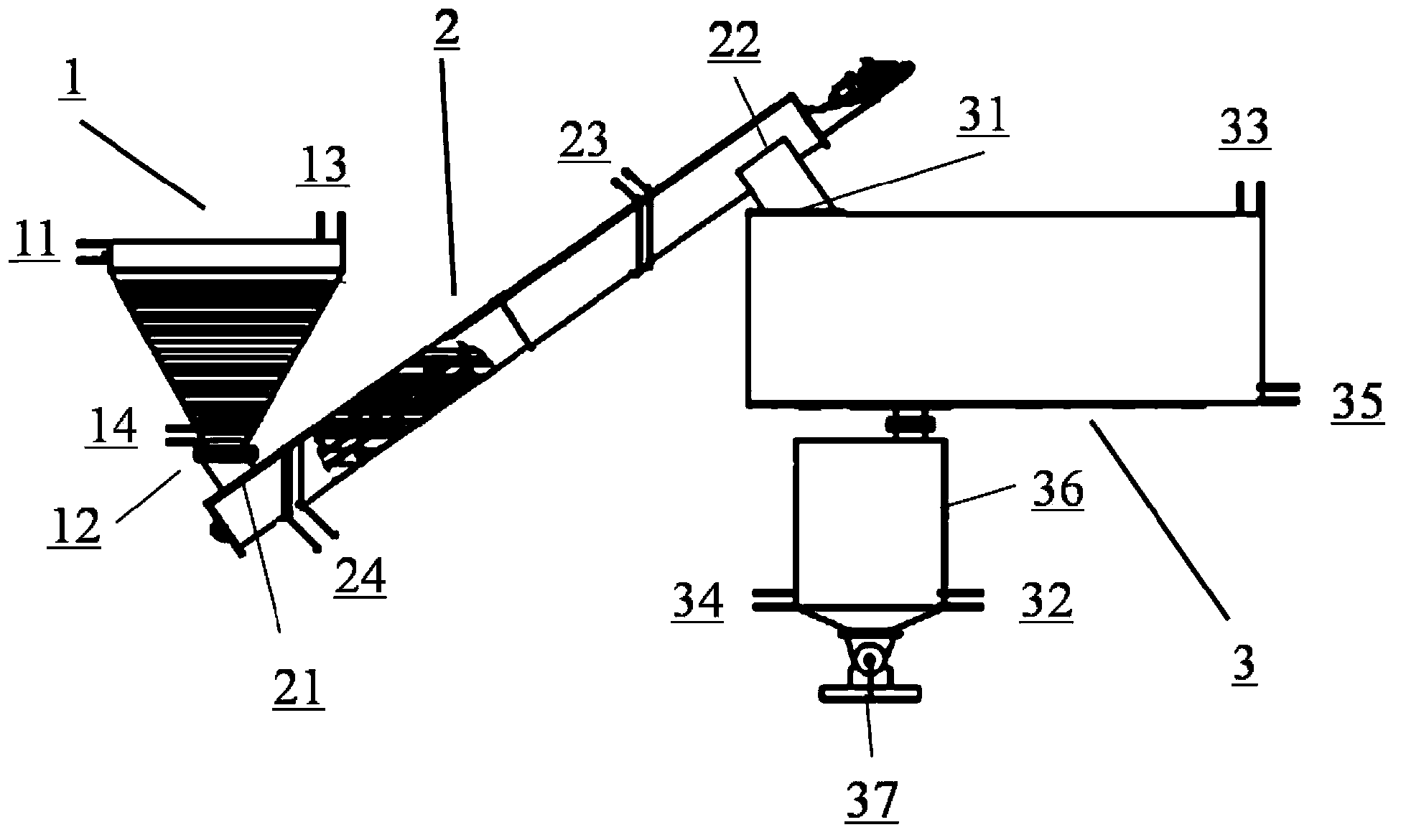

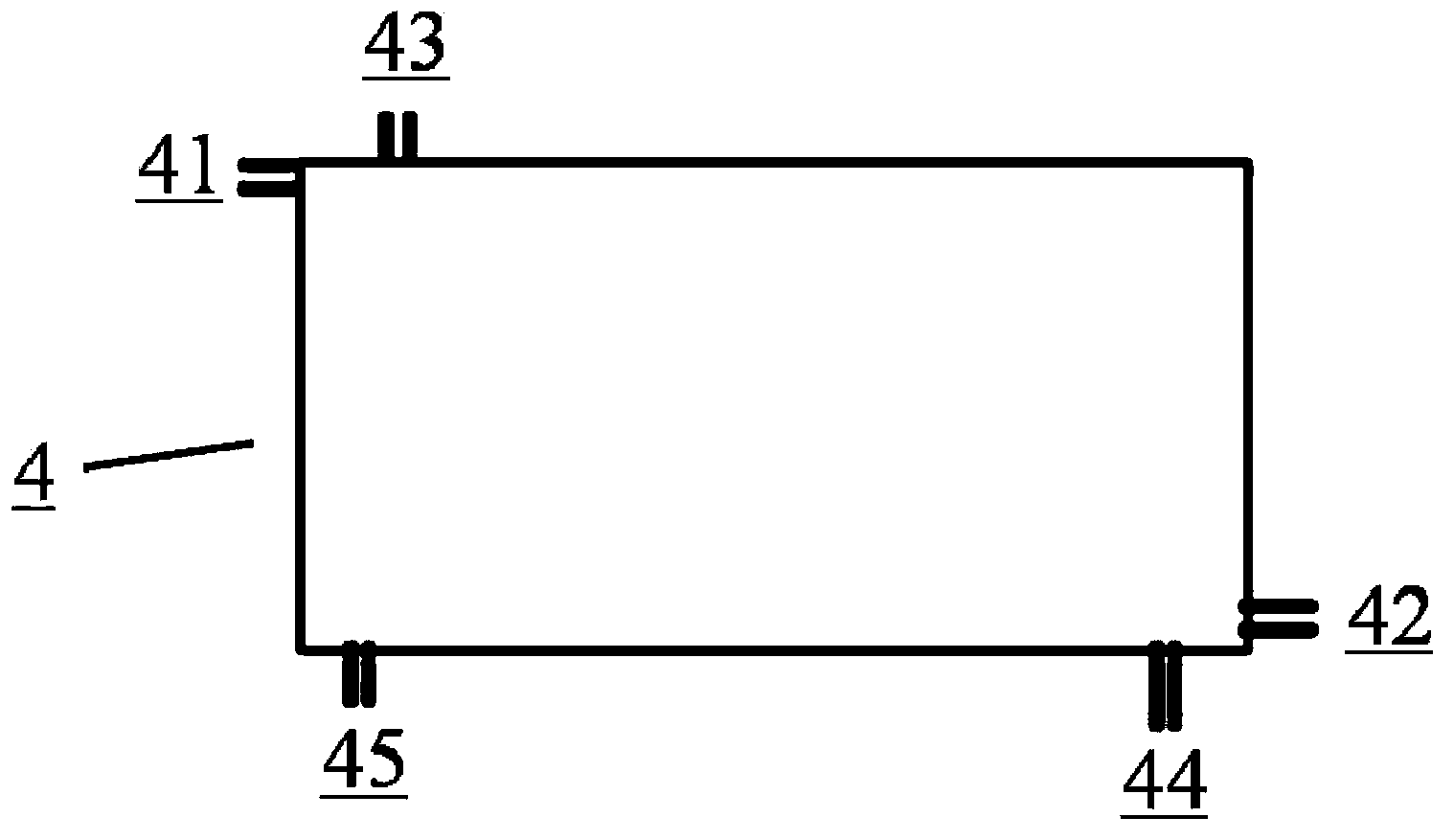

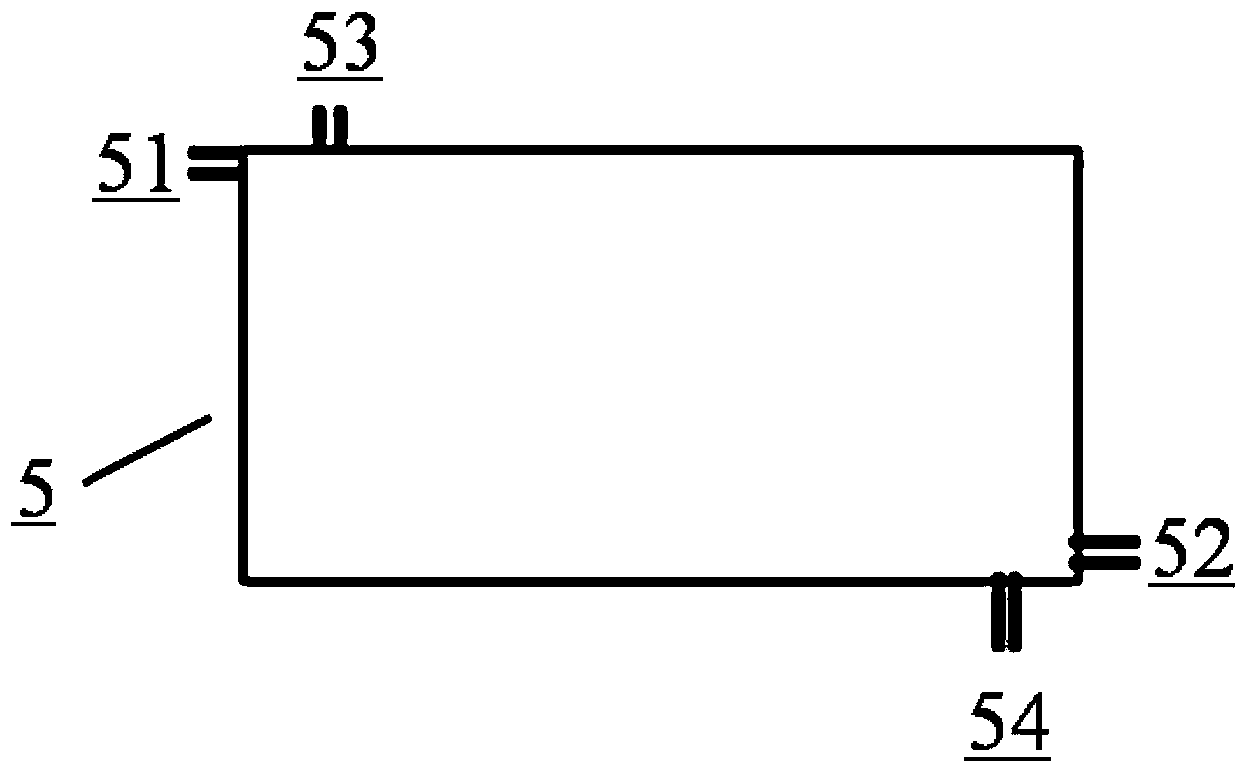

[0099] The use includes raw material buffer tank (1), elevator (2), crusher (3), juice extractor (4), negative pressure evaporator (5), enzymatic clarification tank (6), filtration system (7), The device of the present invention of the sterilizer (8) and the concentrator (9) processes red flesh apples, wherein the hoist (2) used is a screw hoist, and the crusher (3) used is a cold beater machine, the juice extractor (4) used is a screw juice extractor, the filter system (7) used is a horizontal separator, a disc separator and an ultrafiltration unit, and the conditions used include, under negative pressure In the evaporator (5), preheat the turbid apple juice at a temperature of 75-98°C for 20-30s for enzyme inactivation and pre-concentration; in the enzymatic clarification tank (6), use amylase, pectinase, Enzyme and acid protease (the overall dosage is 100-400ppm), enzymolysis and clarification at 30-60°C for 40-90min; in the filtration system, set the horizontal separator t...

Embodiment 2

[0111] Except that the crusher used is a negative pressure crusher, the same method and device as in Example 1 were used to process red-flesh apples and obtain clear red-flesh apple juice.

[0112] The anthocyanin loss, polyphenol oxidase inhibition rate and 5-HMF generation rate of the obtained red flesh apple clear juice were measured. The results showed that the loss of anthocyanins was 15-16%, the inhibition rate of polyphenol oxidase was 89-91%, and the production rate of 5-HMF was 3.5-4.0mg / kg.

Embodiment 3

[0114] Except that enzyme inactivation and pre-concentration were carried out at 80-96° C. in a negative pressure evaporator, the same method and device as in Example 1 were used to process red-flesh apples and obtain red-flesh apple juice.

[0115] The anthocyanin loss, polyphenol oxidase inhibition rate and 5-HMF generation rate of the obtained red flesh apple clear juice were measured. The results showed that the loss of anthocyanins was 16-17%, the inhibition rate of polyphenol oxidase was 94-96%, and the production rate of 5-HMF was 3.5-3.9 mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com