Medical composite polymer material aqueous dispersion and application

A composite polymer and dispersion technology, which is applied in the field of pharmaceuticals, to achieve obvious slow-release effects, improve sticky wall problems, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

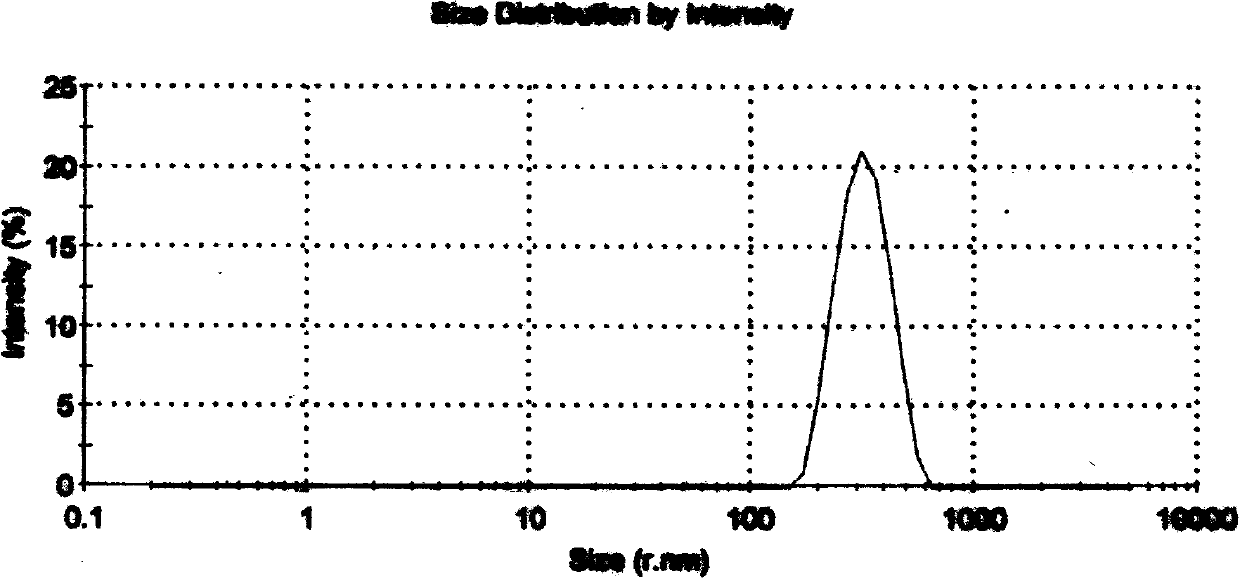

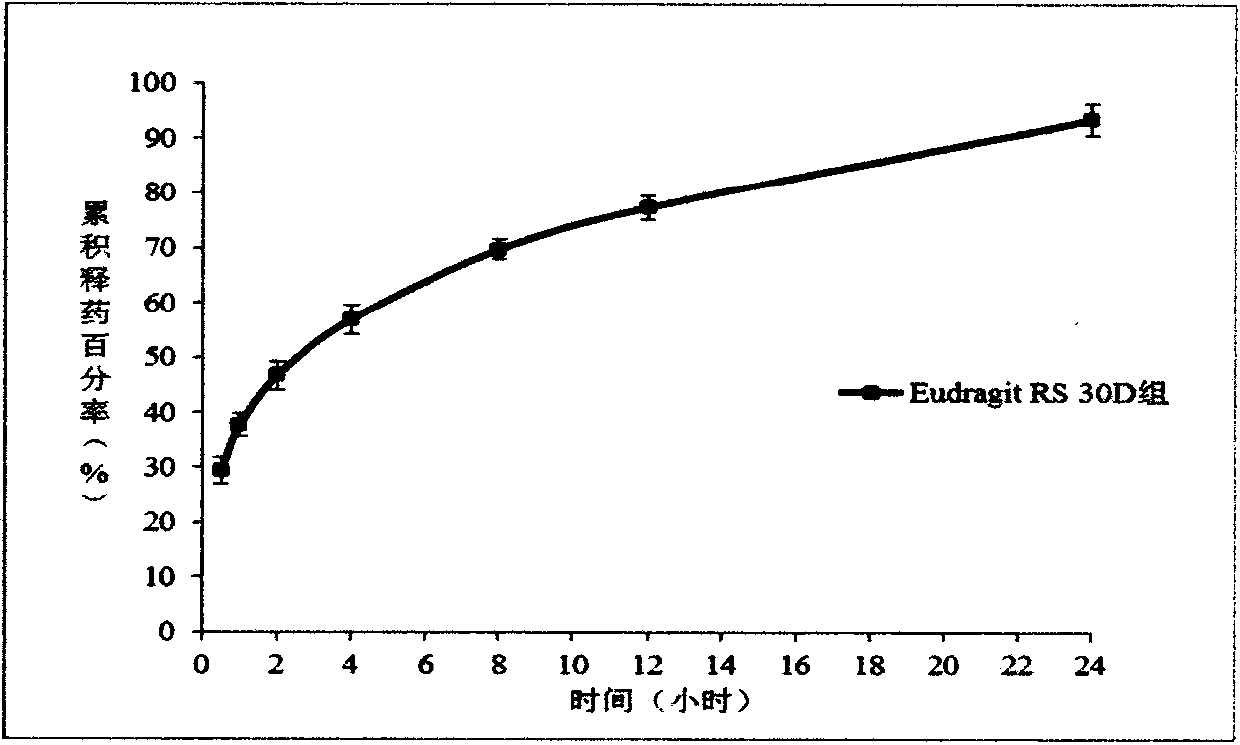

[0050] Place 3 parts by weight of ethyl cellulose and 27 parts by weight of Eudragit RS in 50 parts by weight of absolute ethanol, stir magnetically, dissolve, add 70 parts by weight of distilled water, stir evenly, and volatilize to remove the ethanol in the mixed solution to obtain A homogeneous aqueous dispersion of composite polymers with a solids content of 30%.

[0051] The water dispersion, dexketoprofen and other auxiliary materials are mixed and dispersed evenly according to the prescription ratio, and then spray-dried, and the final product yield is 64.51% on average.

Embodiment 2

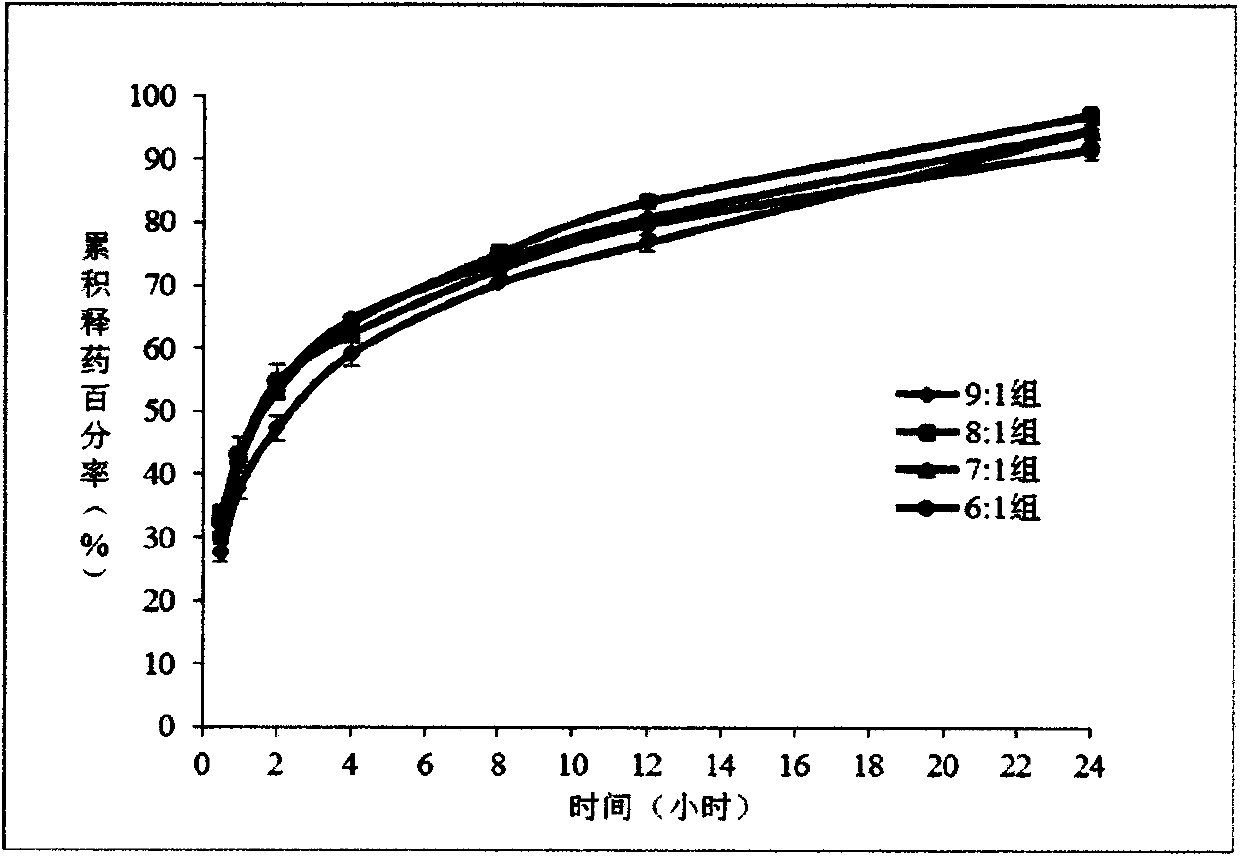

[0053] Place 3 parts by weight of ethyl cellulose and 24 parts by weight of Eudragit RS in 50 parts by weight of absolute ethanol, stir magnetically, dissolve, add 63 parts by weight of distilled water, stir evenly, and volatilize to remove the ethanol in the mixed solution to obtain A homogeneous aqueous dispersion of composite polymers with a solids content of 30%.

[0054] The water dispersion, dexketoprofen and other auxiliary materials are mixed and dispersed evenly according to the prescription ratio, and then spray-dried, and the final product yield is 61.03% on average.

Embodiment 3

[0056] Place 3 parts by weight of ethyl cellulose and 21 parts by weight of Eudragit RS in 50 parts by weight of absolute ethanol, stir magnetically, dissolve, add 56 parts by weight of distilled water, stir evenly, and volatilize to remove the ethanol in the mixed solution to obtain A homogeneous aqueous dispersion of composite polymers with a solids content of 30%.

[0057] The water dispersion, dexketoprofen and other auxiliary materials are mixed and dispersed evenly according to the prescription ratio, and then spray-dried, and the average yield of the final product is 52.57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com