Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., to achieve the effects of strong heavy oil cracking ability, good resistance to metal pollution, and high liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

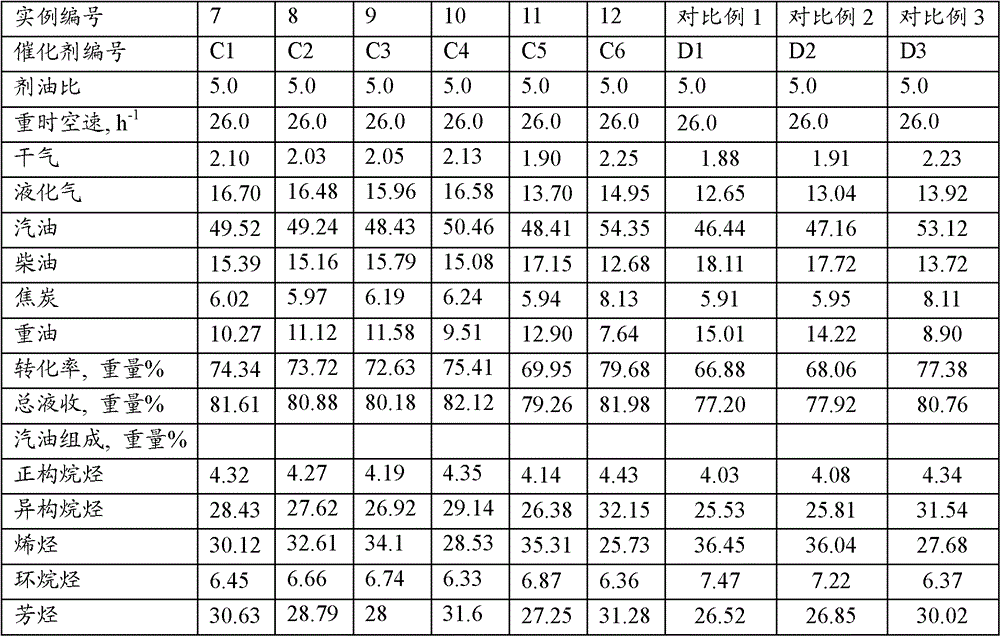

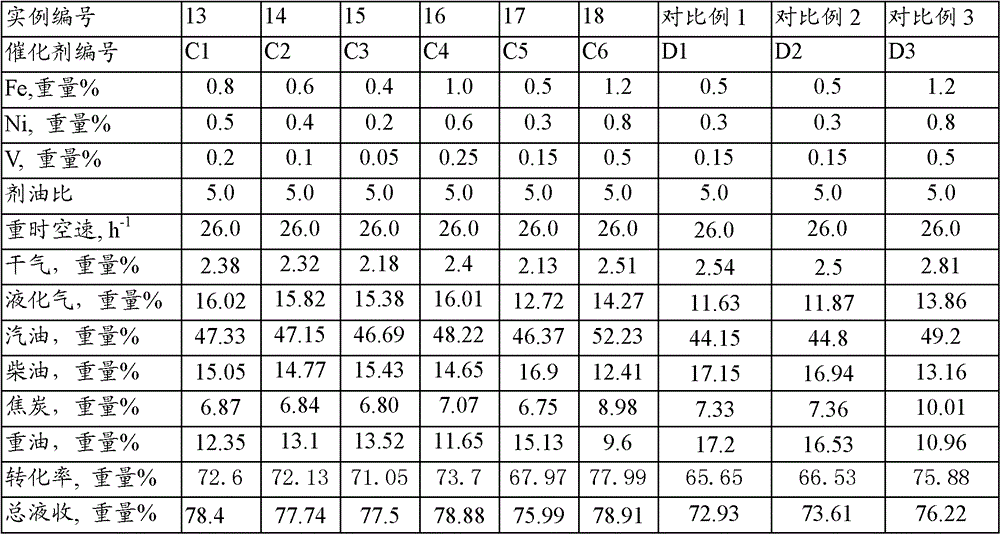

Examples

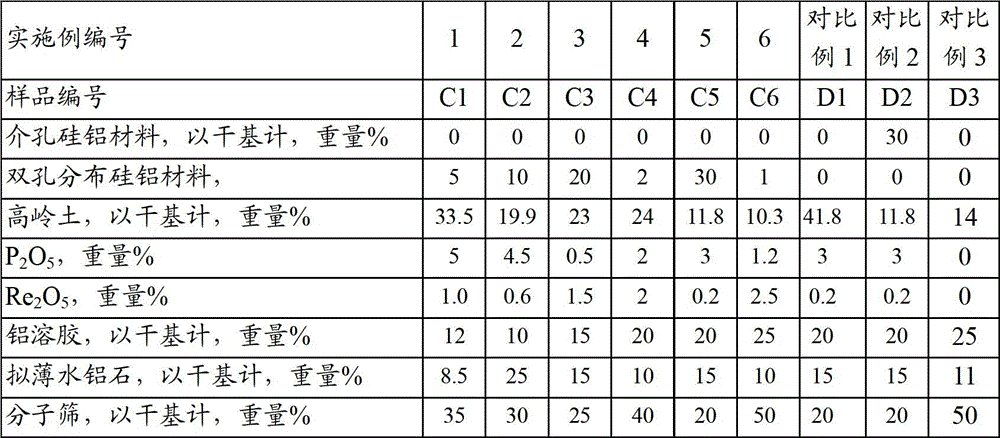

preparation example Construction

[0026] In the preparation method of the catalytic cracking catalyst provided by the present invention, the binder is preferably pseudo-boehmite and alumina sol, and the silica-alumina material with dual-pore distribution is added before the alumina sol and molecular sieve. When the phosphorus modifier and / or the rare earth modifier are included in the catalyst, the phosphorus modifier and the rare earth modifier are introduced into the silicon-aluminum material containing double pores distribution, molecular sieves before spray drying and forming , clay and binder slurry.

[0027] A preferred preparation method is to mix and beat the double-pore distribution silicon-alumina material, pseudoboehmite, kaolin and water, add hydrochloric acid to acidify, and then add aluminum sol and Y-type molecular sieve to prepare slurry. In the case of rare earth modifiers, phosphorus modifiers and rare earth modifiers can be added before the active components or after the active components. ...

preparation Embodiment 1

[0032] Ethyl orthosilicate (Sinopharm Chemical Reagent Co., Ltd., SiO 2 The mass content is 28.0%) as the silicon source, aluminum nitrate as the aluminum source, and the mixture of starch and sodium dodecyl sulfate (SDS) as the template to prepare the dual-pore distribution silicon-alumina material.

[0033] At room temperature, 8.59g tetraethyl orthosilicate (Sinopharm Chemical Reagent Co., Ltd., SiO 2 Mass content 28.0%), 0.23g aluminum nitrate (Al(NO 3 ) 3 , Shanghai Zhenxin Reagent Factory, mass content 99.0%), 1.71g soluble starch (Sinopharm Chemical Reagent Co., Ltd., analytical grade) and 1.68g SDS (Sinopharm Chemical Reagent Co., Ltd., mass content 86.0%) were added to 36ml of water, stirred For 2 hours, adjust the pH value to 6.0 with a 10% by weight hydrochloric acid solution, stir for 6 hours, stop stirring, age at 100°C for 24 hours, filter the resulting mixture, wash with deionized water, and then dry at 100°C for 10 hours , calcined at 550°C for 9 hours to ob...

preparation Embodiment 2

[0035] Sodium silicate was used as the silicon source, aluminum isopropoxide was used as the aluminum source, and a mixture of sucrose and cetyltrimethylammonium bromide (CTAB) was used as the template to prepare a dual-pore distribution silica-alumina material.

[0036] 11.78g sodium silicate (Na 2 SiO 3 9H 2 O, Sinopharm Chemical Reagent Co., Ltd., Na 2 O mass content 19.3-22.8%), 0.62g aluminum isopropoxide (Sinopharm Chemical Reagent Co., Ltd., Al mass content 24.7%), 1.98g sucrose (Sinopharm Chemical Reagent Co., Ltd., analytically pure) and 1.10g CTAB (Sinopharm Group Chemical Reagent Co., Ltd., mass content 99.0%) was added into 36ml of water, stirred for 2 hours, adjusted to a pH value of 10.0 with a 10% by weight aqueous sodium hydroxide solution, stirred for another 6 hours, stopped stirring, and aged at 80°C for 48 hours; the resulting mixture was filtered and washed, then dried at 100°C, and then calcined at 600°C for 6 hours to obtain a dual-pore distribution s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com