Green and quick method for preparing lignin-nanosilver sol

A nano-silver sol and lignin technology, applied in the field of nanometers, can solve problems such as environmental pollution, difficult separation of nano-silver, and restrictions on the application of nano-silver, achieving high efficiency, simple operation, and easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

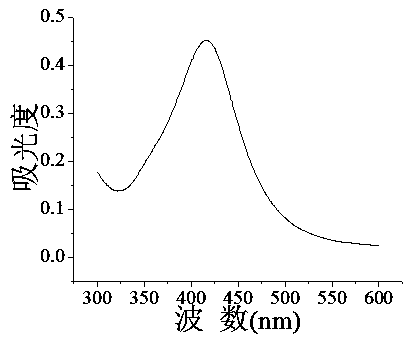

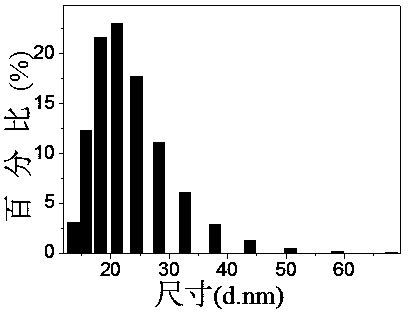

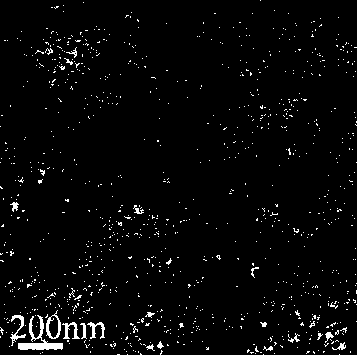

Embodiment 1

[0028] In a dark environment, the NaOH solution with a mass concentration of 100 mg / mL was slowly added dropwise to 100 mg / mL AgNO 3 solution (0.2040 g AgNO 3 ), stirring while adding dropwise until no more precipitation occurs, then slowly add ammonia water with a mass fraction of 20% to the mixed solution, continue stirring, stop adding ammonia water when the precipitate is completely dissolved, dilute with ultrapure water, and prepare 25 mL of [Ag(NH 3 ) 2 ] + solution. Then 0.3 g of lignin acetate (molecular weight 3500 g / mol and having guaiacyl (G), syringyl (S) and p-hydroxyphenyl ( H) Three basic unit structures) were dissolved in NaOH solution with a mass fraction of 2%, and made into a lignin solution with a mass fraction of 0.8%, and placed in a microwave reactor after stirring evenly, and the microwave radiation power was adjusted to 700 W, The microwave irradiation temperature was 50 °C. Then inject the newly prepared silver ammonia solution into the lignin s...

Embodiment 2

[0030] Slowly add NaOH solution with a mass concentration of 50 mg / mL to 50 mg / mL AgNO in a dark environment 3 solution (0.7140 g AgNO 3 ), stirring while adding dropwise until no more precipitation occurs, then slowly add ammonia water with a mass fraction of 25% into the mixed solution, continue stirring, stop adding ammonia water when the precipitate is completely dissolved, dilute with ultrapure water, and prepare 30 mL of [Ag(NH 3 ) 2 ] + solution. Then 0.35 g of alkali lignin (molecular weight 4000 g / mol and having guaiacyl (G), syringyl (S) and p-hydroxyphenyl ( H) three basic unit structures) were dissolved in NaOH solution with a mass fraction of 5%, and made into a lignin solution with a mass fraction of 2%, and placed in a microwave reactor after being stirred evenly, and the microwave radiation power was adjusted to 600 W, The microwave irradiation temperature was 70 °C. Then inject the newly prepared silver ammonia solution into the lignin solution through t...

Embodiment 3

[0032] In a dark environment, the NaOH solution with a mass concentration of 150 mg / mL was slowly added dropwise to 60 mg / mL AgNO 3 solution (0.2975 g AgNO 3 ), stirring while adding dropwise until no more precipitation occurs, then slowly add ammonia water with a mass fraction of 15% into the mixed solution, continue stirring, stop adding ammonia water when the precipitate is completely dissolved, dilute with ultrapure water, and prepare 20 mL of [Ag(NH 3 ) 2 ] + solution. Then 0.25 g of alkali lignin (molecular weight 5000 g / mol and having guaiacyl (G), syringyl (S) and p-hydroxyphenyl ( H) Three basic unit structures) were dissolved in NaOH solution with a mass fraction of 3%, and made into a lignin solution with a mass fraction of 1.5%, and placed in a microwave reactor after stirring evenly, and the microwave radiation power was adjusted to 700 W, The microwave irradiation temperature is 60 °C. Then inject the newly prepared silver ammonia solution into the lignin s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com