Manufacturing method of spherical milling cutter with micro-cutting milling blade array structure

A technology of spherical milling cutter and array structure, which is applied to milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive processing, and achieve the effect of avoiding secondary clamping and tool replacement and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

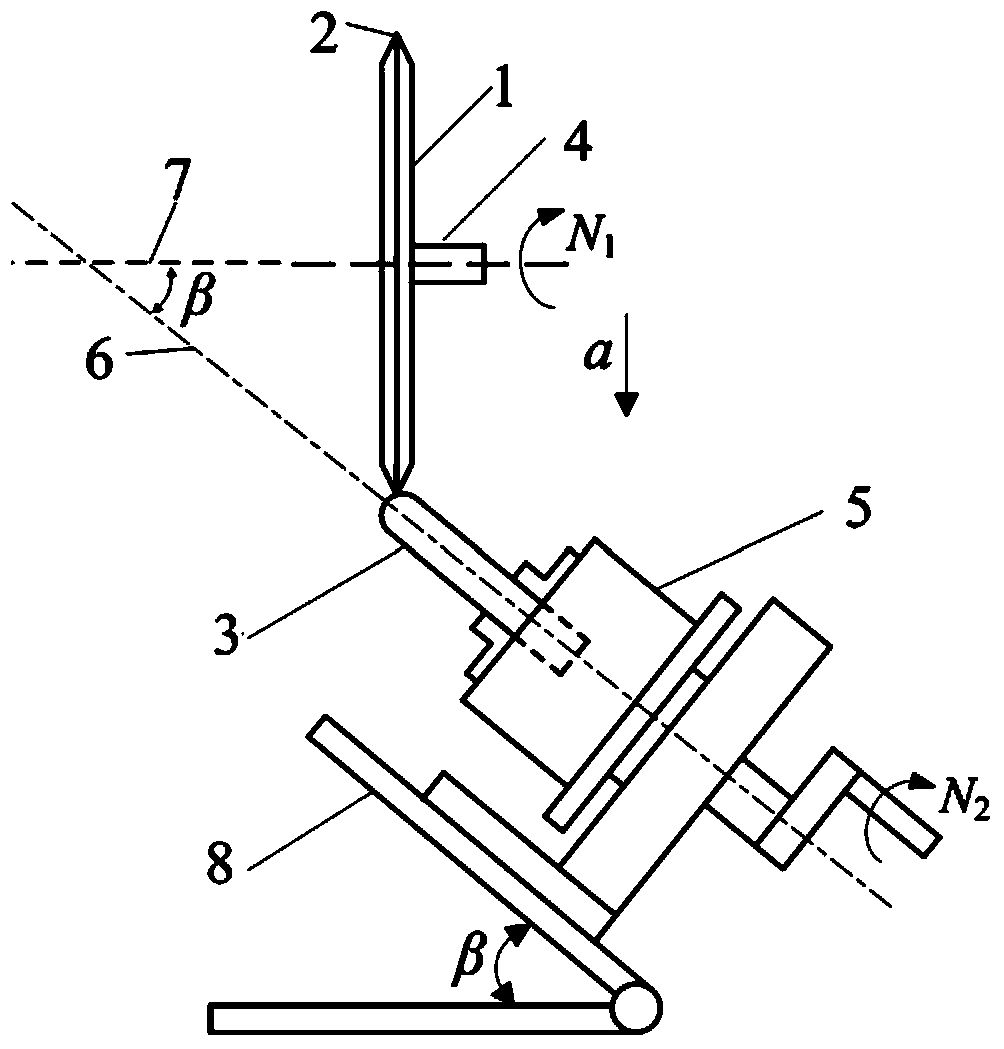

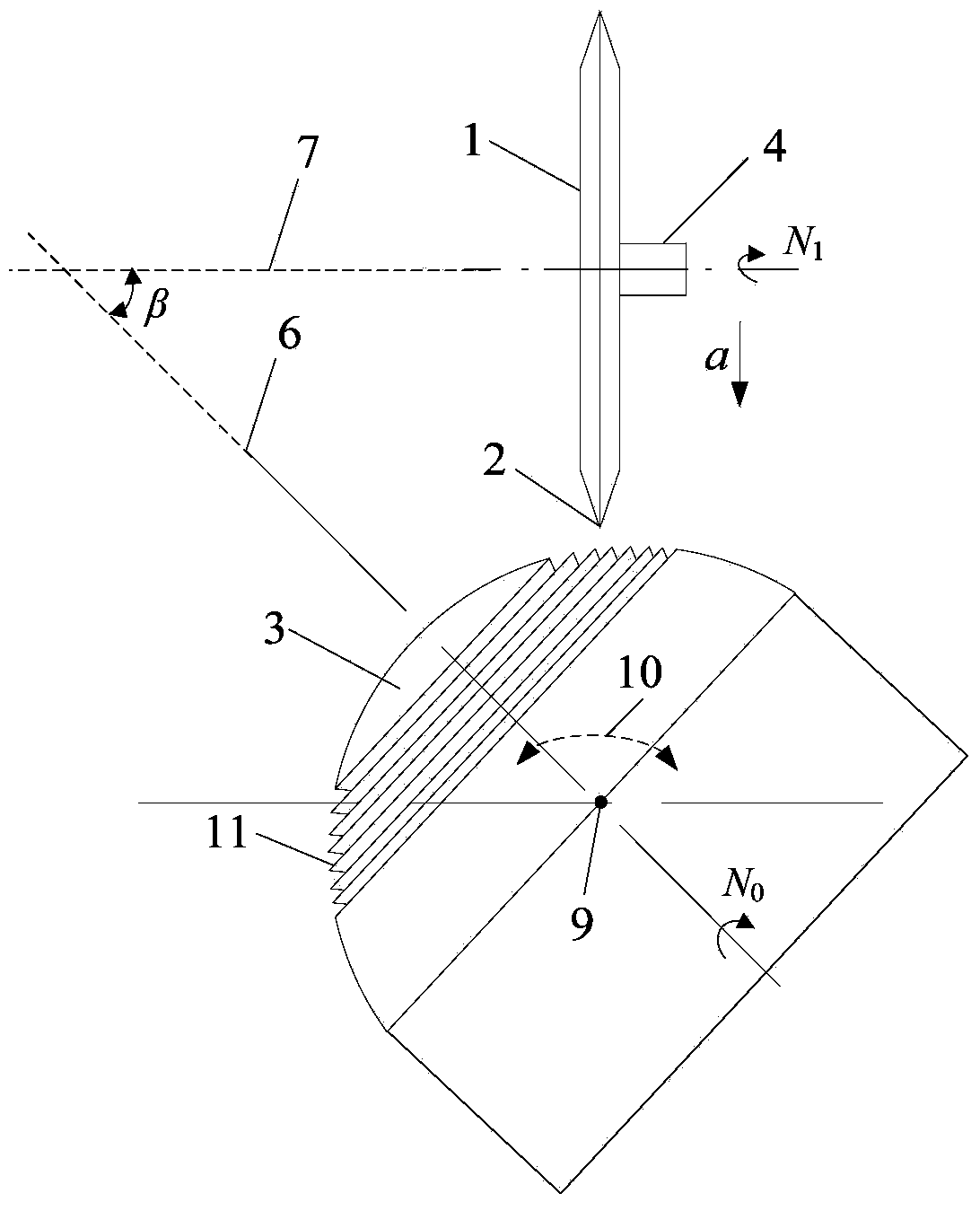

[0028] Such as figure 1 As shown, a diamond grinding wheel 1 (diameter 160 mm, thickness 4 mm) was finely trimmed into a V-shaped tip 2 and installed on the grinding wheel shaft 4 of a CNC precision grinding machine (SMART‐B818). Then place the indexer 8 (MCL-C3×4) on the horizontal workbench, then place the fixture (Michelin three-jaw grinder MCL-550) 5 on the indexer 8, and place the double-edged spherical milling cutter 3 (ball head radius 6mm , the diameter of the milling cutter is 12mm, and the length of the milling cutter is 75mm) is clamped on the fixture 5, so that the angle β between the axis 6 of the spherical milling cutter and the axis 7 of the grinding wheel is 45 degrees. The V-tip diamond grinding wheel has a particle size of 600 mesh and is composed of diamond abrasive and bronze bond. The included angle of the V-tip of the grinding wheel is 60 degrees. The material of the spherical milling cutter is tungsten carbide with a hardness of 70-80HRC.

[0029] Such...

Embodiment 2

[0032] The processing mode of this embodiment is the same as that of Embodiment 1. The difference is that when using a spherical milling cutter with a micro-cutting edge structure array to mill the micro-groove structure surface of G-STAR die steel (HRC40-50), the milling cutter speed is 3000 rpm and the feed rate is 100 mm / min with a feed depth of 10 microns. The processed micro-groove structure has a depth of 90 microns, a groove angle of 63.5 degrees, a tip radius of 15 microns at the bottom of the groove, and a micro-groove spacing of 600 mm. The surface of the micro-grooves is smooth without burrs.

Embodiment 3

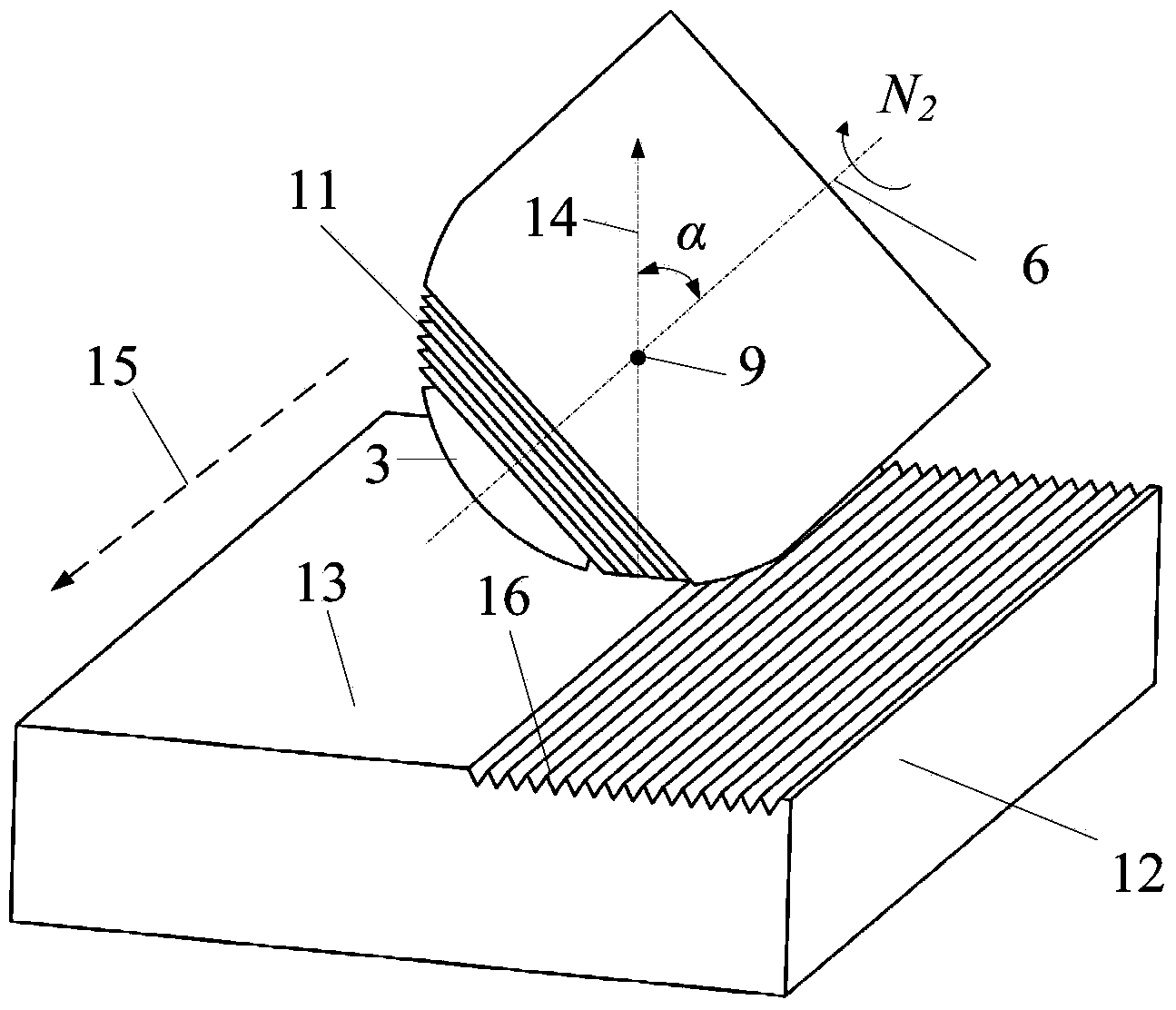

[0034] Such as Figure 4 As shown, if the surface of the workpiece 12 is designed with a curved surface 13, the aluminum alloy workpiece is first processed into a curved surface with a spherical milling cutter without a micro-cutting edge structure array. The measurement is 0.5mm, the tool radius is 6mm, the rotational speed is 5000rpm, and the feed rate is 1000mm / min. Then, a spherical milling cutter with a micro-cutting edge structure array is used to produce a micro-groove array on the processed curved surface. The grooving processing parameters are 0.1 mm back cut, 5000 rpm rotation speed, and 800 mm / min feed speed. Specifically, in the milling process, the normal direction 14 of the tangent point between the spherical surface of the milling cutter and any curved surface of the workpiece is always maintained at a fixed angle α=45°, and the spherical milling cutter is processed along the curved surface where the normal radius of the tangent point is r The knife track 15 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com