Graphene/manganese tetraoxide nanocomposite and preparation method thereof

A technology of nano manganese tetraoxide and composite materials, which is applied in chemical instruments and methods, manganese oxide/manganese hydroxide, carbon compounds, etc., can solve problems such as complex synthesis processes, achieve large specific surface area, simple method, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

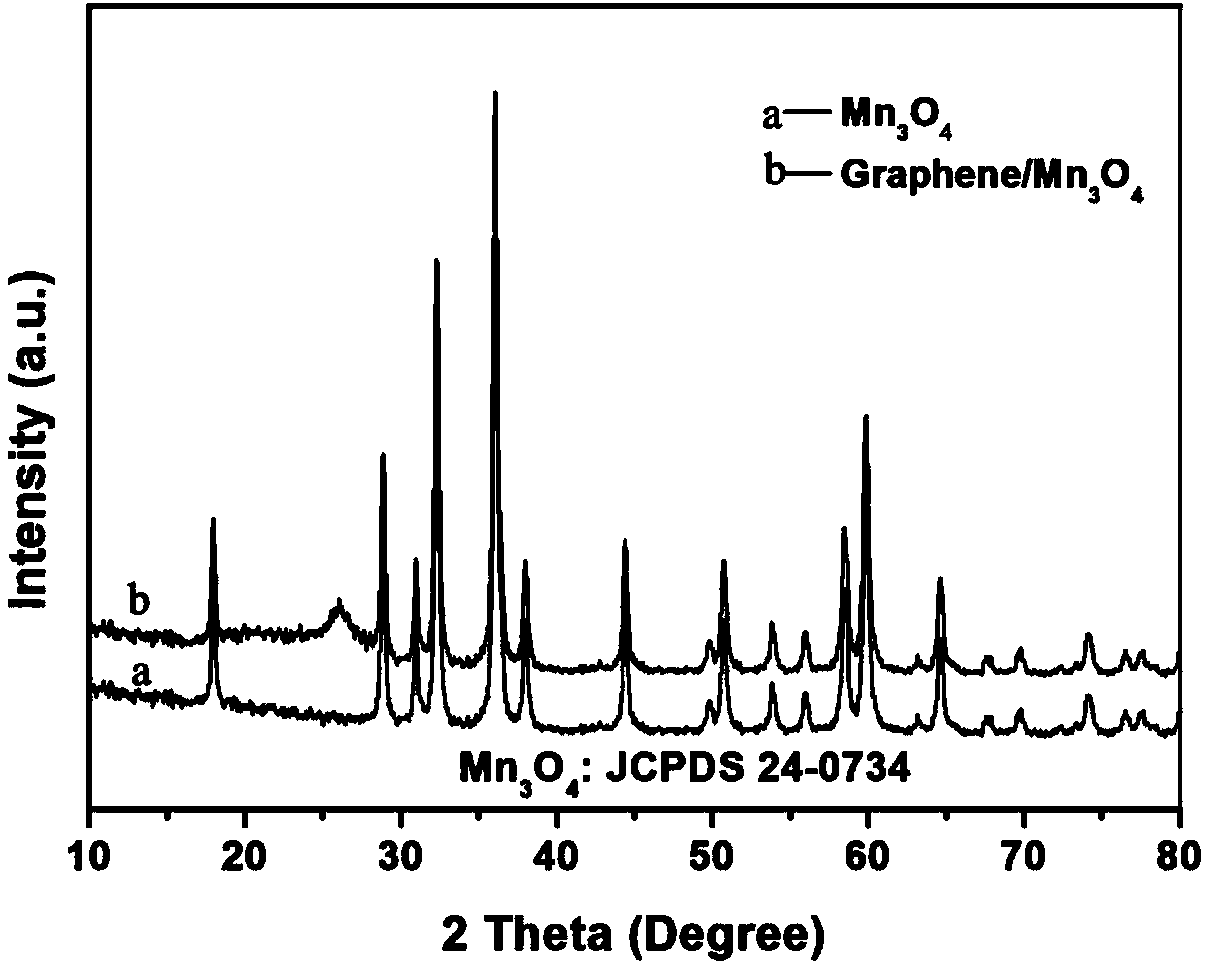

[0032] Take 1mL of 10mg / mL graphite oxide concentrate and put it in a beaker, add 39mL of deionized water to obtain a graphene oxide solution with a concentration of 0.25mg / mL, stir evenly, ultrasonicate in a water bath at room temperature for 10min, then place the beaker in an ice water bath, And further ultrasonicated for 60min under the power of 240W of the probe ultrasonic processor; add 1mmol potassium permanganate to the above 0.25mg / mL graphene oxide solution, stir until the potassium permanganate is completely dissolved, then add 1000μL to it with a mass fraction of 35% hydrazine hydrate, stirred for 20 minutes to make it evenly mixed; pour the above mixed solution into a 50mL reaction kettle, and react at 100°C for 8 hours. After the reaction is completed, take it out after cooling. The reaction product is brownish yellow, indicating the formation of manganese oxide. The product was repeatedly washed by centrifugation and vacuum-dried at 80°C for 12 hours to obtain a t...

Embodiment 2

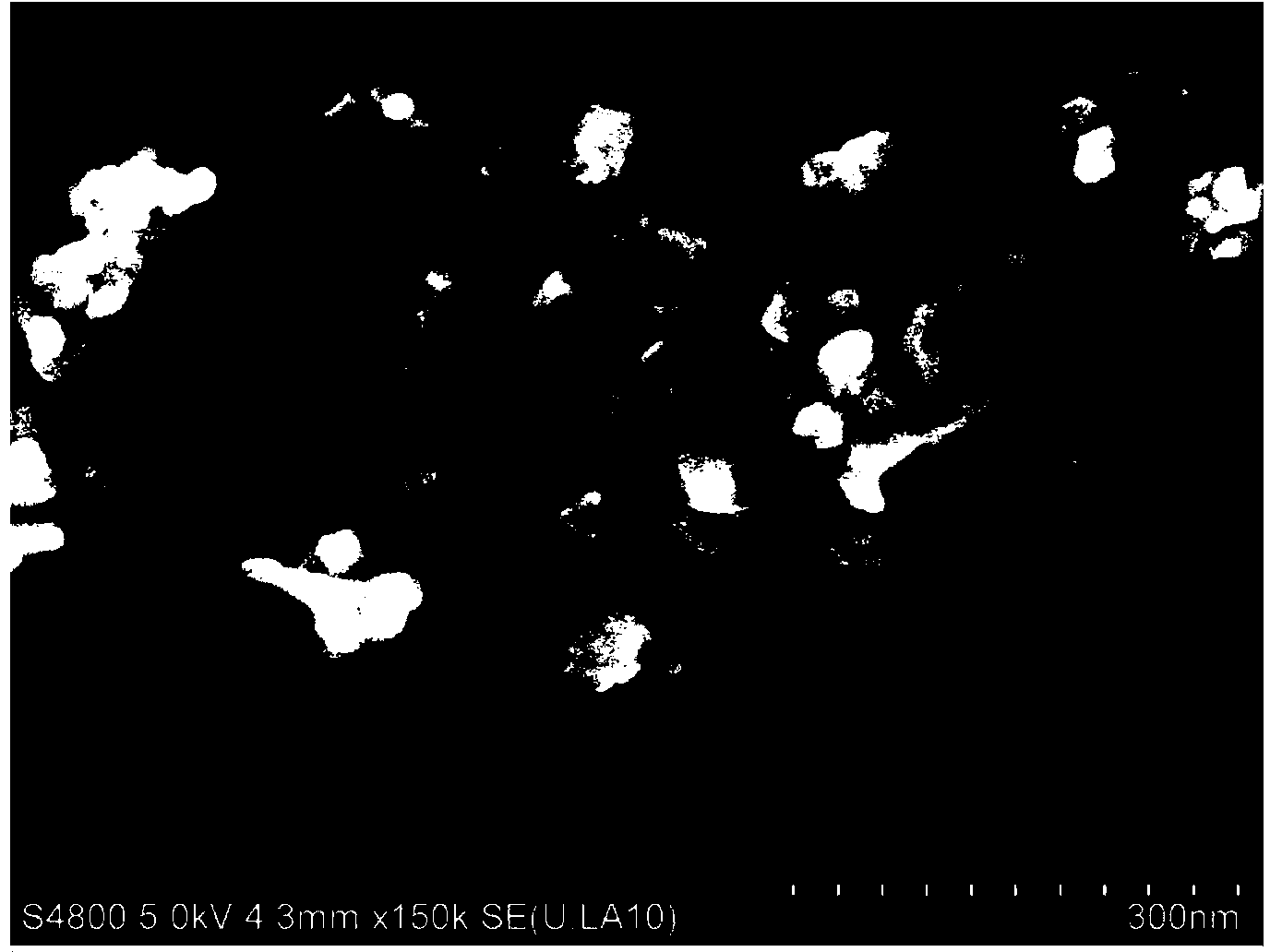

[0034] Take 2mL of 10mg / mL graphite oxide concentrate and put it in a beaker, add 38mL of deionized water to dilute the concentration of graphite oxide solution to 0.5mg / mL, stir evenly, and put the beaker in an ice water bath after ultrasonication for 10min at room temperature. Sonicate for 60min under the probe ultrasonic processor at 240W power; add 1mmol potassium permanganate to the above 0.5mg / mL graphene oxide solution, stir until the potassium permanganate is completely dissolved, add 1000μL of hydrazine hydrate with a mass fraction of 35%, and stir 20min to make it evenly mixed; pour the above mixed solution into a 50mL reaction kettle, react at 100°C for 8h, the reaction product is washed repeatedly by centrifugation, and vacuum dried at 80°C for 12h to obtain a graphene / manganese tetraoxide nanocomposite material , and trimanganese tetraoxide particles are evenly attached to the graphene surface, and trimanganese tetraoxide is spherical or square, such as figure 2 ...

Embodiment 3

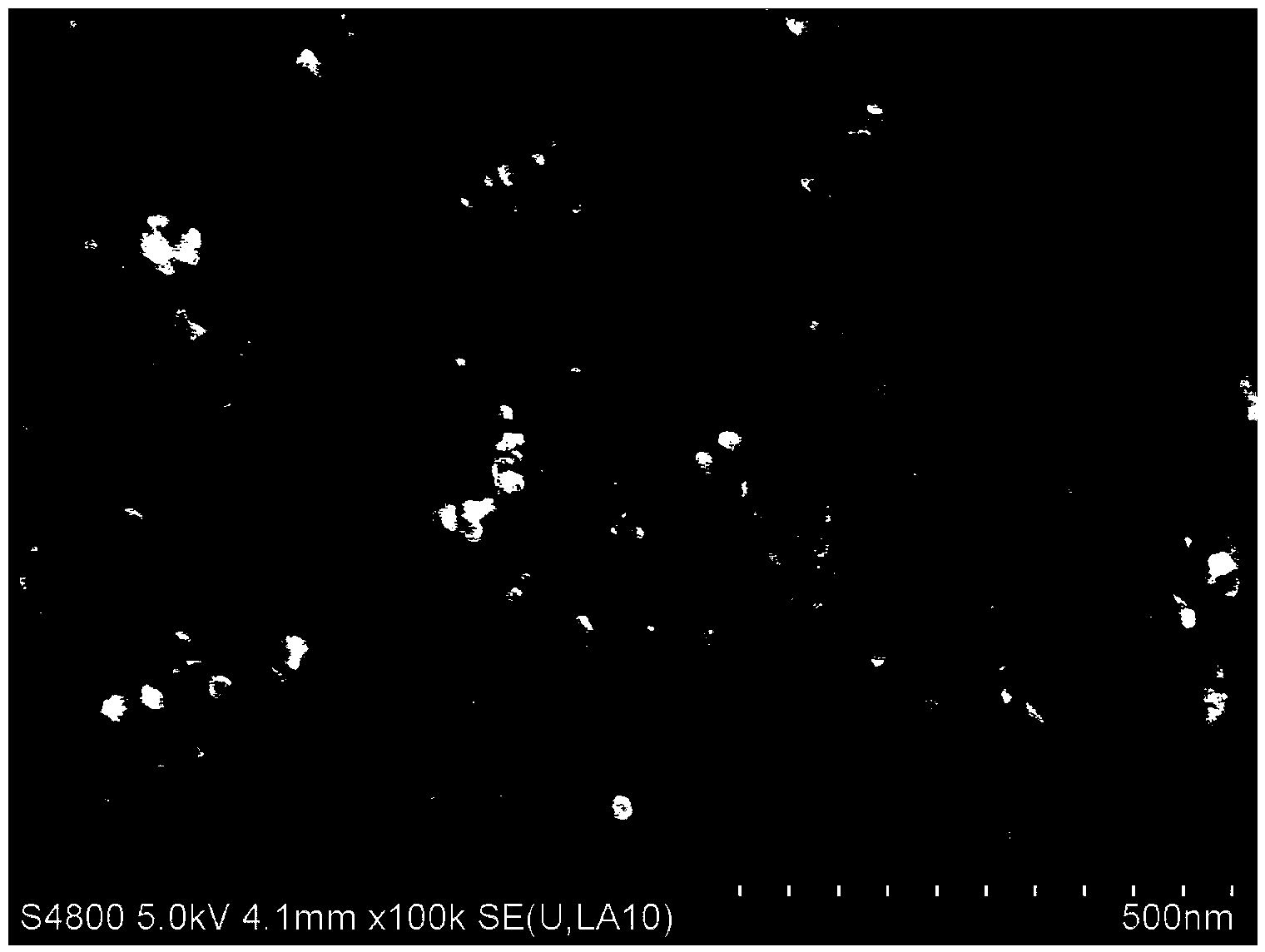

[0036]Take 1mL of 10mg / mL graphite oxide concentrate and put it in a beaker, add 39mL of deionized water to dilute the concentration of graphite oxide solution to 0.25mg / mL, stir evenly, and put the beaker in an ice water bath after ultrasonication for 10min at room temperature. Ultrasonicate for 60min at a probe ultrasonic processor with a power of 240W; add 1mmol potassium permanganate to the above 0.25mg / mL graphene oxide solution, stir until the potassium permanganate is completely dissolved, add 1000μL of hydrazine hydrate with a mass fraction of 35%, and stir Mix it uniformly for 20 minutes; pour the above mixed solution into a 50mL reaction kettle, react at 80°C for 8h, and the reaction product is washed repeatedly by centrifugation and vacuum dried at 80°C for 12h to obtain a graphene / manganese tetraoxide nanocomposite material , and manganese tetraoxide is spherical, with a diameter of about 20nm, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com