Preparation method for molded biomass active carbon with crop straw as raw material

A technology for crop straw and biomass, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of inconvenient transportation and dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

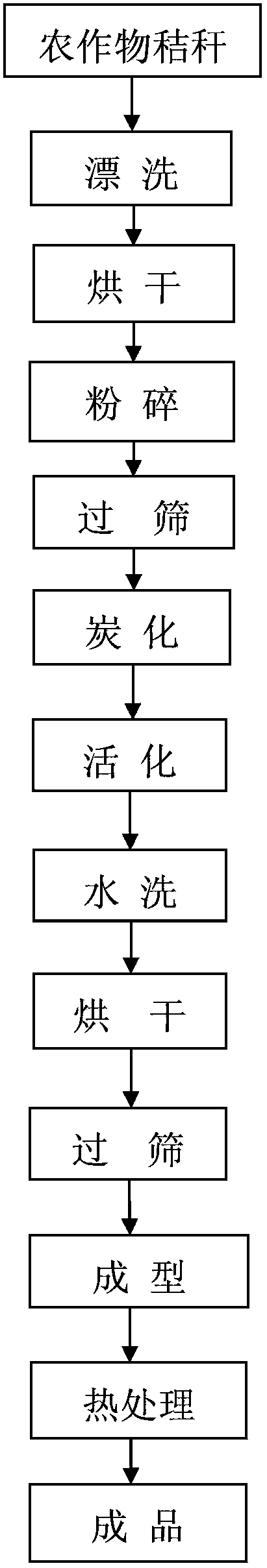

[0008] A method for preparing shaped biomass activated carbon from crop stalks, comprising the following steps:

[0009] (1) Rinsing: Rinse crop straw with water to remove surface adherents;

[0010] (2) Drying: drying the rinsed straw at 105°C;

[0011] (3) Pulverization: pulverize the dried straw with a pulverizer;

[0012] (4) Sieving: pass the crushed straw through a 60-mesh sieve;

[0013] (5) Carbonization: straw powder is anaerobically carbonized at 700°C for 8 hours;

[0014] (6) Activation: carbonized straw powder is activated by adding 1mol / L phosphoric acid;

[0015] (7) Washing: Wash the activated carbon powder to neutrality;

[0016] (8) Drying: Dry the charcoal powder washed to neutral;

[0017] (9) Sieving: the dried charcoal powder is passed through a 60-mesh sieve to obtain powdery biomass activated carbon;

[0018] (10) Molding: After mixing the sieved powdered biomass activated carbon with 15% sodium carboxymethylcellulose (CMC) aqueous solution, press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com