Method for refining crude glycerine being by-product of biodiesel

A technology of biodiesel and crude glycerin, which is applied in the chemical industry, can solve the problems of high cost of pure glycerin, and achieve the effects of reducing the cost of glycerin recovery and refining, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

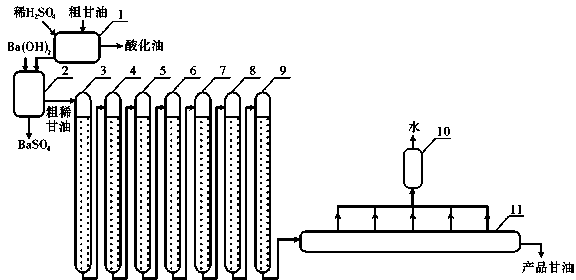

[0019] A method for refining crude glycerin, a by-product of biodiesel, comprising the following steps: adding crude glycerol produced in the biodiesel production process into an acidification reactor, adjusting the pH to 5 with dilute sulfuric acid, and acidifying at 45°C for 30 minutes; the upper layer The acidified oil is returned to the biodiesel production system as a raw material for biodiesel production. The glycerol solution in the lower layer enters the neutralization reactor, and the pH is adjusted to 7.5 with barium hydroxide solution, and the stratification is allowed to stand; the resulting precipitate is discharged from the bottom of the reactor, and the obtained dilute glycerin Solution cation exchange column, anion exchange column and mixed anion and cation exchange column remove various impurities to obtain a dilute glycerin solution; the dilute glycerol solution enters a short-distance pipeline evaporator for thin-layer efficient rapid continuous evaporation an...

Embodiment 2

[0021] A method for refining crude glycerin, a by-product of biodiesel, comprising the following steps: adding crude glycerol produced in the biodiesel production process into an acidification reactor, adjusting the pH to 6 with dilute sulfuric acid, and acidifying at 50°C for 60 minutes; the upper layer The acidified oil is returned to the biodiesel production system as a raw material for biodiesel production. The glycerol solution in the lower layer enters the neutralization reactor, and the pH is adjusted to 8.5 with barium hydroxide solution, and the stratification is allowed to stand; the resulting precipitate is discharged from the bottom of the reactor, and the obtained dilute glycerin Solution cation exchange column, anion exchange column and mixed anion and cation exchange column remove various impurities to obtain a dilute glycerin solution; the dilute glycerol solution enters a short-distance pipeline evaporator for thin-layer efficient rapid continuous evaporation an...

Embodiment 3

[0023] A method for refining crude glycerin, a by-product of biodiesel, comprising the following steps: adding crude glycerol produced in the biodiesel production process into an acidification reactor, adjusting the pH to 5.5 with dilute sulfuric acid, and acidifying at 53°C for 45 minutes; the upper layer The acidified oil is returned to the biodiesel production system as a raw material for biodiesel production. The glycerol solution in the lower layer enters the neutralization reactor, and the pH is adjusted to 8.0 with barium hydroxide solution, and the stratification is allowed to stand; the resulting precipitate is discharged from the bottom of the reactor, and the obtained dilute glycerin Solution cation exchange column, anion exchange column and mixed anion and cation exchange column remove various impurities to obtain a dilute glycerin solution; the dilute glycerol solution enters a short-distance pipeline evaporator for thin-layer efficient rapid continuous evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com