Diimidazole diiodide platinum/polymer hybrid proton exchange membrane and preparation method thereof

A proton exchange membrane and diimidazole technology, which is applied in the field of diimidazole diiodide platinum/polymer hybrid proton exchange membrane and its preparation, can solve the problems of hybrid membrane proton conduction performance decline, proton transfer channel tortuous, etc., to achieve Good industrial production basis, improved proton conductivity, and the effect of increasing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

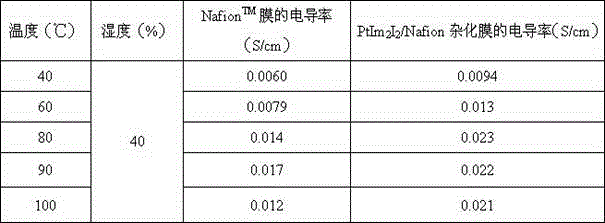

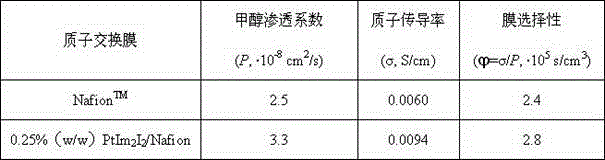

Embodiment 1

[0021] At room temperature, in a dark environment, 60 mg of potassium chloroplatinite (K 2 [PtCl 4 ]) was dissolved in 7ml of deionized water, and ultrasonically placed to obtain a uniform solution; 10mg of potassium iodide (KI) was added to the above solution, and allowed to react for 30min; finally, 15mg of imidazole (Im) was added to the above mixture, and allowed to react 24h. The brown-yellow precipitate obtained above is washed with a large amount of deionized water and absolute ethanol, and finally the product is dried, and the product obtained is denoted as PtIm 2 I 2 , that is, diimidazole diiodoplatinum. PtIm 2 I 2 Dissolved in N,N-dimethylformamide to give 0.5% (w / w) of PtIm 2 I 2 / DMF solution. Take a certain amount of Nafion TM After the solution was rotary evaporated, N,N-dimethylformamide was added to obtain a 100 mg / ml Nafion / DMF solution, and the rotary evaporation was continued for 10 minutes. Add a certain amount of 0.5% (w / w) PtIm to the above sol...

Embodiment 2

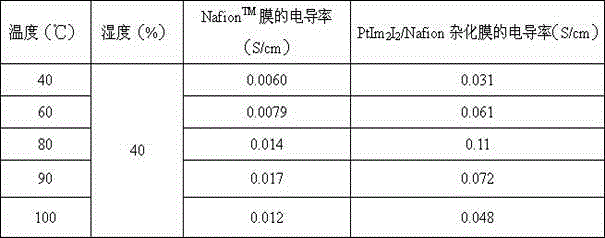

[0028] At room temperature, in a dark environment, 40 mg of potassium chloroplatinite (K 2 [PtCl 4 ]) was dissolved in 7ml of deionized water, and ultrasonically placed to obtain a uniform solution; 10mg of potassium iodide (KI) was added to the above solution, and allowed to react for 30min; finally, 20mg of imidazole (Im) was added to the above mixture, and allowed to react 24h. The brown-yellow precipitate obtained above is washed with a large amount of deionized water and absolute ethanol, and finally the product is dried, and the product obtained is denoted as PtIm 2 I 2 , that is, diimidazole diiodoplatinum. PtIm 2 I 2 Dissolved in N,N-dimethylformamide to give 0.5% (w / w) of PtIm 2 I 2 / DMF solution. Take a certain amount of Nafion TM After the solution was rotary evaporated, N,N-dimethylformamide was added to obtain a 100 mg / ml Nafion / DMF solution, and the rotary evaporation was continued for 10 minutes. Add a certain amount of 0.5% (w / w) PtIm to the above sol...

Embodiment 3

[0035] At room temperature, in a dark environment, 50 mg of potassium chloroplatinite (K 2 [PtCl 4 ]) was dissolved in 7ml of deionized water, and ultrasonically placed to obtain a uniform solution; 200mg of potassium iodide (KI) was added to the above solution, and allowed to react for 30min; finally, 100mg of imidazole (Im) was added to the above mixture, and allowed to react for 24h . The brown-yellow precipitate obtained above is washed with a large amount of deionized water and absolute ethanol, and finally the product is dried, and the product obtained is denoted as PtIm 2 I 2 , that is, diimidazole diiodoplatinum. PtIm 2 I 2 Dissolved in N,N-dimethylformamide to give 0.5% (w / w) of PtIm 2 I 2 / DMF solution. Take a certain amount of Nafion TM After the solution was rotary evaporated, N,N-dimethylformamide was added to obtain a 100 mg / ml Nafion / DMF solution, and the rotary evaporation was continued for 10 minutes. Add a certain amount of 0.5% (w / w) PtIm to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com