Transparent flexible conductive polyimide film

A polyimide film, flexible and conductive technology, applied in the field of transparent and flexible conductive polyimide film, can solve the problems of weak flexibility, difficult sputtering and dispersion of metal components, etc., achieve good conductivity, increase transparency The effect of high lightness and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a flexible conductive polyimide film, carried out according to the following steps:

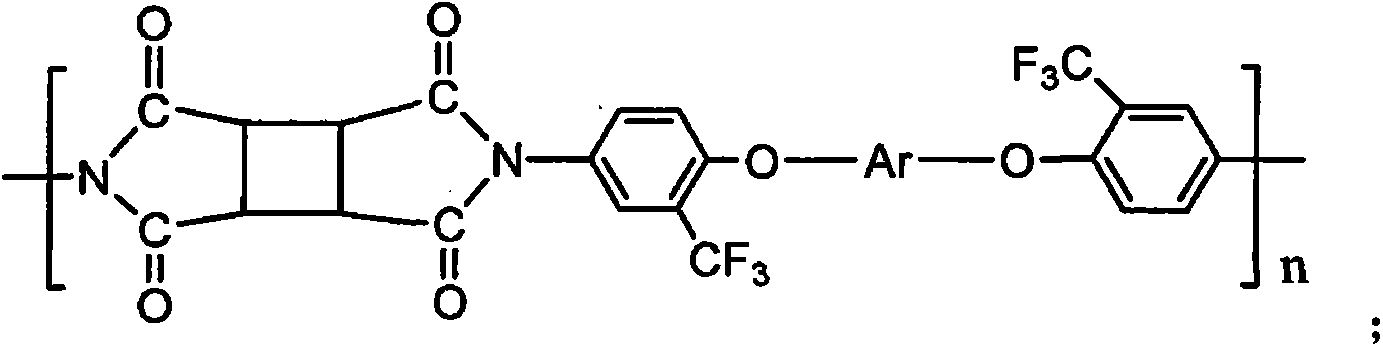

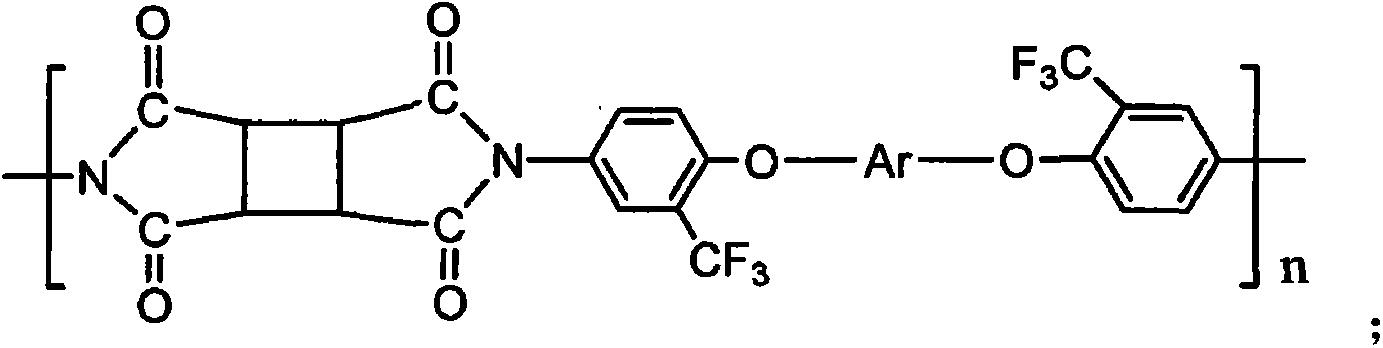

[0026] (1) At room temperature, 4283.3g1, 4-bis(4-amino-2-trifluoromethylphenoxy)benzene and 1961.1g1,2,3,4-cyclobutanetetracarboxylic dianhydride were added to Reactor, under the protection of nitrogen, add 30L m-cresol, stir evenly, add 500mL isoquinoline, heat up to 190°C, react for 12 hours, after cooling, pour the reaction solution into ethanol to precipitate, and make polyimide resin;

[0027] (2) Put 500g of copper and 500g of carbon powder in 10LN, N-dimethylacetamide, add 300g of silane, pre-disperse after high-temperature treatment in a high-shear disperser, and the treatment temperature is 200-800°C;

[0028] (3) Stir the synthesized polyimide resin and the processed copper powder and carbon powder through the stirring reactor, the stirring speed is 1000rpm, the stirring time is 1-2h, add 300g plantain extract, the rotating speed is adjusted to 2000rp...

Embodiment 2

[0034] A preparation method of a flexible conductive polyimide film, carried out according to the following steps:

[0035] (1) At room temperature, mix 5044.2g4,4'-bis(4-amino-2-trifluoromethylphenoxy)biphenyl with 1961.1g1,2,3,4-cyclobutane tetracarboxylic dianhydride Add it to the reaction kettle, add 42L m-cresol under nitrogen protection, stir evenly, add 550mL isoquinoline, raise the temperature to 190°C, and react for 12 hours. After cooling, pour the reaction solution into ethanol to precipitate, and make polyimide resin ;

[0036] (2) Put 600g of silver and 550g of carbon powder in 10LN-methylpyrrolidone, add 320g of titanate, pre-disperse after high-temperature treatment in a high-shear disperser, and the treatment temperature is 200-800°C;

[0037] (3) Stir the synthesized polyimide resin and treated silver powder and carbon powder through a stirring reactor, the stirring speed is 1000rpm, the stirring time is 1-2h, add 320g of plantain extract, the rotating speed ...

Embodiment 3

[0043] A preparation method of a flexible conductive polyimide film, carried out according to the following steps:

[0044] (1) At room temperature, mix 5204.2g2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]diphenyl ether with 1961.1g1,2,3,4-cyclobutyl Add alkanetetracarboxylic dianhydride to the reaction kettle, add 43L m-cresol under nitrogen protection, stir evenly, add 550mL isoquinoline, heat up to 190°C, and react for 12 hours. After cooling, pour the reaction solution into ethanol to precipitate. into polyimide resin;

[0045] (2) Put 600g copper-coated nickel and 550g carbon powder in 10L dimethyl sulfoxide, add 320g isopropyl triisostearyl titanate, and pre-disperse after high-temperature treatment by a high-shear disperser. The treatment temperature is 200-800℃;

[0046] (3) The synthesized polyimide resin and the processed copper-coated nickel and carbon powder are stirred in a stirring reactor, the stirring speed is 1000rpm, and the stirring time is 1-2h, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com