A kind of anti-corrosion foaming agent for natural gas well and preparation method thereof

A foaming agent and natural gas technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of shortening the service life of oil casing, corrosion of oil casing, and the influence of foaming performance of foaming agent, etc., to achieve excellent The effect of corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

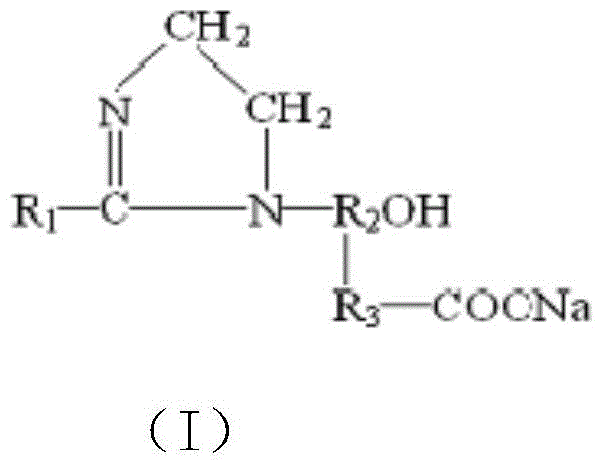

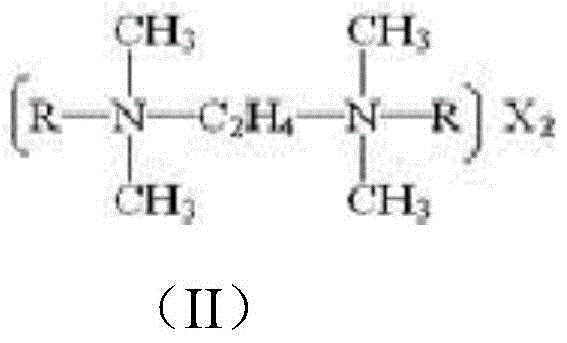

[0036] R1 in the chemical structural formula of imidazoline is a normal alkyl group containing 12 carbon atoms, R2 is a methyl group, and R3 is an ethyl group; in the chemical structural formula of ethylene dialkylammonium halide, R is a normal alkyl group containing 16 carbon atoms Base, X is CL.

[0037] Add 150kg of imidazoline surfactant and 75kg of ethylenedialkylammonium halide into a stainless steel reaction kettle, heat to about 85°C, keep warm until completely dissolved, and stir at 60r / min for 10min; then add 275kg of soft water, Stir at 50r / min for 30min to 35min.

[0038] The corrosion-inhibiting foaming agent in Example 1 was tested under conditions comparable to the natural gas well environment, and the foaming height, liquid carrying capacity and corrosion inhibition rate were measured. During the experiment, the dosage of corrosion inhibitor and foaming agent was 3g / L, that is, 3g of corrosion inhibitor and foaming agent was used per liter of mineralized water...

Embodiment 2

[0040] R1 in the chemical structural formula of imidazoline is a normal alkyl group containing 13 carbon atoms, R2 is an ethyl group, and R3 is an ethyl group; in the chemical structural formula of ethylene dialkylammonium halide, R is a normal alkyl group containing 17 carbon atoms Base, X is CL.

[0041] Add 165kg of imidazoline surfactant and 100kg of ethylenedialkylammonium halide into a stainless steel reaction kettle, heat it to about 85°C, keep it warm until it is completely dissolved, and stir at 60r / min for 115min; then add 235kg of soft water, Stir at 50r / min for 30min to 35min.

[0042] The corrosion inhibitor foaming agent in Example 2 was tested under the same conditions as in Example 1, and the evaluation conditions and results are shown in Table 1.

Embodiment 3

[0044] R1 in the chemical structural formula of imidazoline is a normal alkyl group containing 14 carbon atoms, R2 is a methyl group, and R3 is a propyl group; in the chemical structural formula of ethylene dialkylammonium halide, R is a normal alkyl group containing 18 carbon atoms Base, X is Br.

[0045] Add 175kg of imidazoline surfactant and 125kg of ethylene dialkylammonium halide into the stainless steel reaction kettle, heat to about 85°C, keep warm until completely dissolved, stir at 60r / min for 10min~15min; then add 200kg of soft water , stirring at 50r / min for 30min to 35min.

[0046] The corrosion inhibitor foaming agent in Example 3 was tested under the same experimental conditions as Example 1, and the evaluation conditions and results are shown in Table 1.

[0047] Table 1: Evaluation conditions and results of corrosion inhibitor foaming agents

[0048]

[0049]

[0050] In summary, the corrosion inhibitor and foaming agent for natural gas wells provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com