Instrument grade silicon carbide reinforced aluminum matrix composite for aviation and preparation method thereof

A technology for strengthening aluminum-based and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of thermal stability, strength and plastic toughness, etc., and achieve high specific stiffness , low density, and the effect of wear-resistant thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

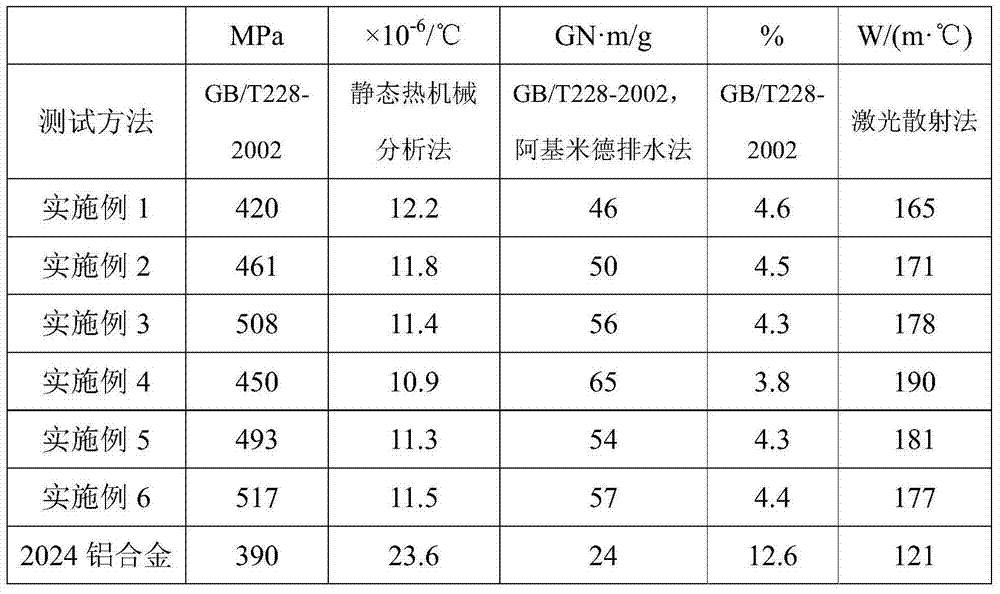

Embodiment 1

[0029] The instrument-grade SiC-reinforced aluminum-based composite material for aviation in this embodiment is made of the following raw materials in volume percentage: 1% of nano-SiC particles, 35% of Micro-SiC particles, and the balance is aluminum alloy powder. The D50 of the nano silicon carbide particles is 60nm; the D50 of the micron silicon carbide particles is 3 μm; the size of the aluminum alloy powder is 10 μm.

[0030] The nano-silicon carbide particles are prepared by the following method: the micro-silicon carbide particles are ball-milled, the balls of the ball mill are zirconia, the diameter of the balls is 5 mm, the ball-to-material ratio is 20:1, and the ball mills for 15 hours to obtain .

[0031] The preparation method of the aviation instrument grade silicon carbide reinforced aluminum matrix composite material of this embodiment comprises the following steps:

[0032] 1) Ingredients: Under the protection of argon gas, take nano-silicon carbide particles,...

Embodiment 2

[0039] The instrument-grade silicon carbide reinforced aluminum matrix composite material for aviation in this embodiment is made of the following raw materials in volume percentage: 3% of nanometer silicon carbide particles, 35% of micron silicon carbide particles, and the balance is aluminum alloy powder. The D50 of the nano silicon carbide particles is 60nm; the D50 of the micron silicon carbide particles is 2 μm; the size of the aluminum alloy powder is 10 μm.

[0040] The nano-silicon carbide particles are prepared by the following method: ball-milling the micro-silicon carbide particles, the balls of the ball milling are zirconia, the diameter of the balls is 10 mm, the ball-to-material ratio is 40:1, and the ball mills for 20 hours to obtain .

[0041] The preparation method of the aviation instrument grade silicon carbide reinforced aluminum matrix composite material of this embodiment comprises the following steps:

[0042] 1) Ingredients: Under the protection of arg...

Embodiment 3

[0049] The instrument-grade silicon carbide reinforced aluminum matrix composite material for aviation in this embodiment is made of the following raw materials in volume percentage: 5% of nanometer silicon carbide particles, 35% of micron silicon carbide particles, and the balance is aluminum alloy powder. The D50 of the nano silicon carbide particles is 60nm; the D50 of the micron silicon carbide particles is 2 μm; the size of the aluminum alloy powder is 10 μm.

[0050] The nano-silicon carbide particles are prepared by the following method: ball-milling the micro-silicon carbide particles, the balls of the ball milling are zirconia, the diameter of the balls is 15 mm, the ball-to-material ratio is 80:1, and the ball mills for 35 hours to obtain .

[0051] The preparation method of the aviation instrument grade silicon carbide reinforced aluminum matrix composite material of this embodiment comprises the following steps:

[0052] 1) Ingredients: Under the protection of arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com