A preparation method of superplastic magnesium alloy with spherical second phase

A magnesium alloy, superplastic technology, applied in the rolling field of high-performance superplastic magnesium alloy, can solve problems such as difficult to realize large-scale sample preparation and mass production, irregular second phase morphology, easy segregation distribution, etc. Achieve small size, improve superplastic deformation ability, and round shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

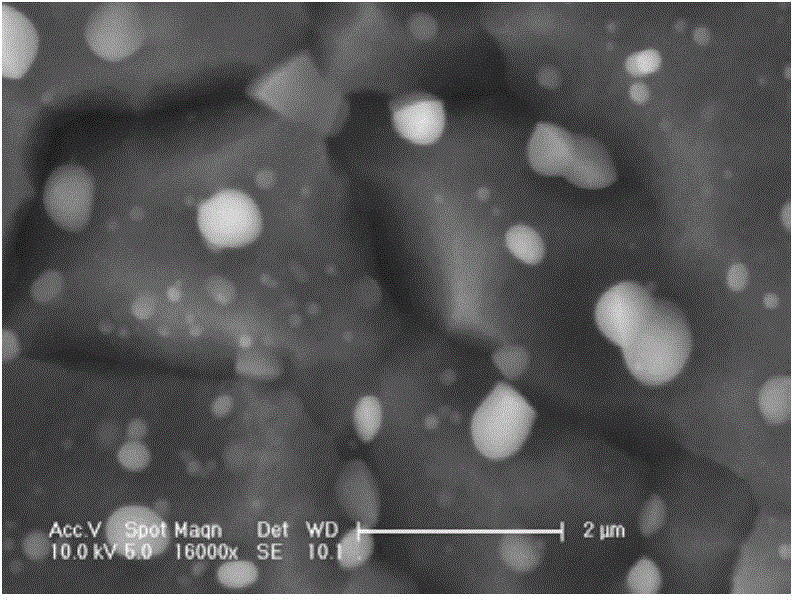

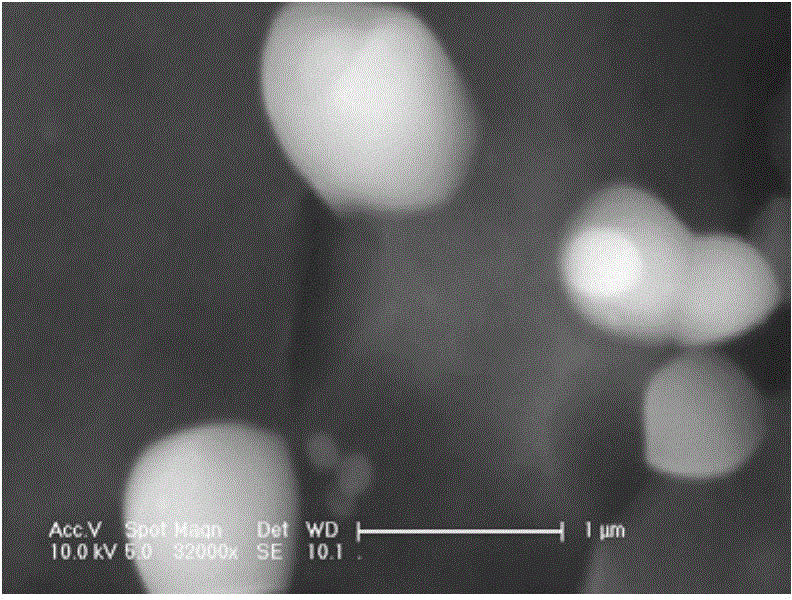

Image

Examples

Embodiment 1

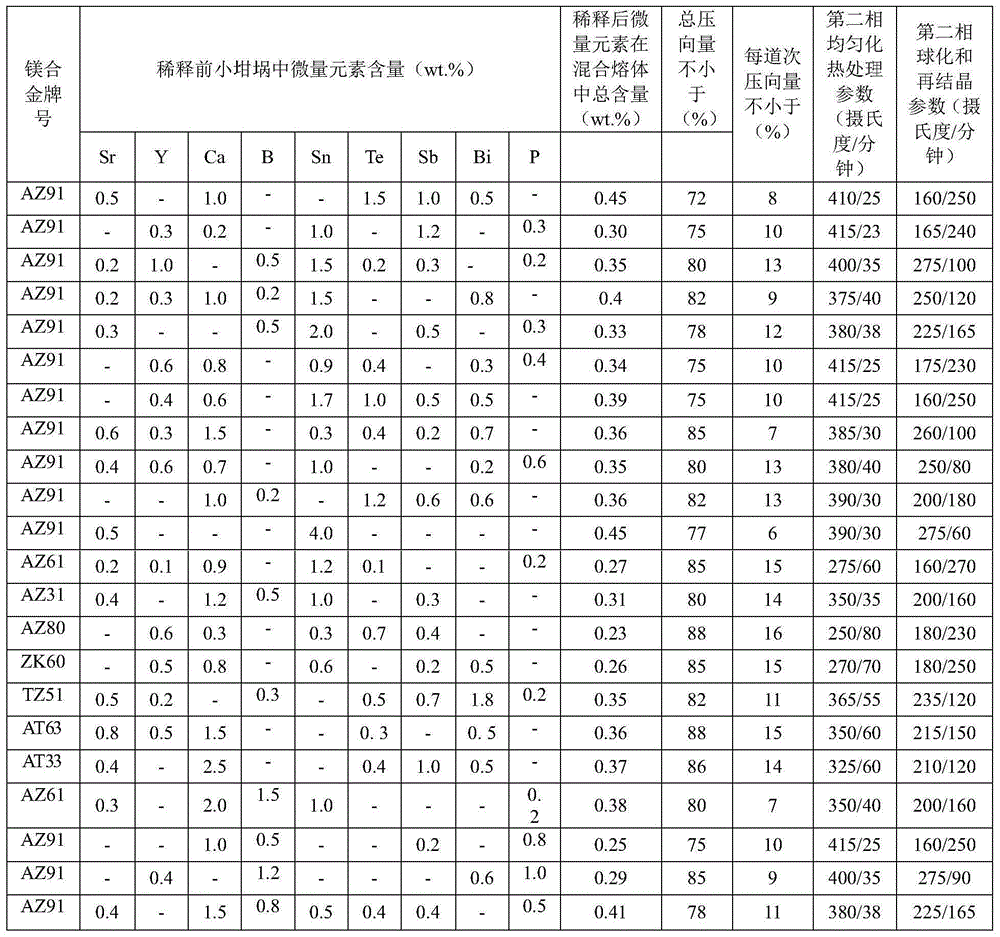

[0031] (1) Inoculation and deterioration treatment:

[0032] ① The commercial AZ91 magnesium alloy is conventionally melted, and after refining, gas blowing purification and slag removal, it is kept at a temperature above 660 degrees Celsius to form a commercial magnesium alloy melt;

[0033] ② Put a certain quality of the above-mentioned commercial magnesium alloy or pure magnesium into another small graphite crucible, heat it to 660-850 degrees Celsius under the protection of argon to melt, add at least one of the trace elements strontium, yttrium, calcium, and boron, Blow argon and stir, continue to add at least one of the trace elements tin, tellurium, antimony, bismuth, and phosphorus, blow argon and stir, so that the elements in the melt can fully react; the total mass of the added trace elements is the same as that in the graphite crucible The ratio of the total mass of the melt is less than or equal to 5%;

[0034] ③According to the ratio of the mass of the commercial...

Embodiment 2

[0041] (1) Inoculation and deterioration treatment:

[0042] ① The commercial AZ31 magnesium alloy is conventionally melted, and after refining, gas blowing purification and slag removal, it is kept at 680 degrees Celsius to form a commercial magnesium alloy melt;

[0043] ② Put a certain quality of the above-mentioned commercial magnesium alloy or pure magnesium into another small graphite crucible, heat it to 660-850 degrees Celsius under the protection of argon to melt, add at least one of the trace elements strontium, yttrium, calcium, and boron, Stir with argon blowing, continue to add at least one of the trace elements tellurium, antimony, and bismuth, blow argon and stir to make the elements in the melt fully react; the total mass of the added trace elements is equal to the total mass of the melt in the graphite crucible The ratio is less than or equal to 4%;

[0044]③According to the dilution ratio of the mass of the commercial magnesium alloy melt prepared above to t...

Embodiment 3

[0051] (1) Inoculation and deterioration treatment:

[0052] ①The ZK60 magnesium alloy is conventionally melted, and after refining, gas blowing purification and slag removal treatment, it is kept at a temperature above 660 degrees Celsius to form a commercial magnesium alloy melt;

[0053] ② Put a certain quality of the above-mentioned commercial magnesium alloy or pure magnesium into another small graphite crucible, heat it to 660-850 degrees Celsius under the protection of argon to melt, add at least one of the trace elements strontium, yttrium, and calcium, and blow argon Gas stirring, continue to add at least one of the trace elements tin, tellurium, antimony, bismuth, phosphorus, blowing argon and stirring, so that the elements in the melt fully react; the total mass of the added trace elements is the same as that of the melt in the graphite crucible The ratio of total mass is less than or equal to 5%;

[0054] ③Pour the melt in the graphite crucible containing trace el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com