A kind of double wavy linear nylon 6 filament and its preparation method

A nylon and wave technology, applied in the field of differential chemical fiber, can solve the problems of affecting the wearing performance and style of fabrics, unable to produce colorful fibers, poor moisture permeability and bulkiness, etc. The effect of resilience, soft luster and good warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment adopts the one-step method of melt spinning and stretching, and the nylon 6 chips are melted by the screw, and the melt is input into the metering pump and the spinning assembly, and the melt is extruded from the spinneret with 40 spinneret holes to form a melt Fine flow, cooling and solidification in the cooling zone of the surrounding air blowing, clustering and oiling, drafting and heat setting, winding and forming, and a double wavy linear nylon 6 filament is obtained.

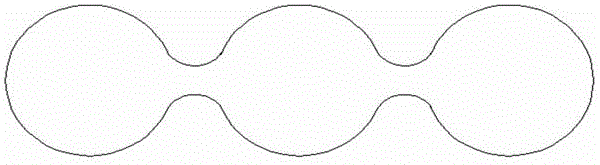

[0020] See attached figure 1 , which is a schematic diagram of the cross-sectional shape of a double-wave linear spinneret hole provided in this embodiment; the hole shape of the spinneret hole is a double-wave linear flat shape, and along the length direction of the spinneret hole, both sides are symmetrical waves The wavy line is composed of 3 identical arc-shaped curves, and they are connected to each other; the height of the arc-shaped curve is 0.045mm; the width of the narrow pa...

Embodiment 2

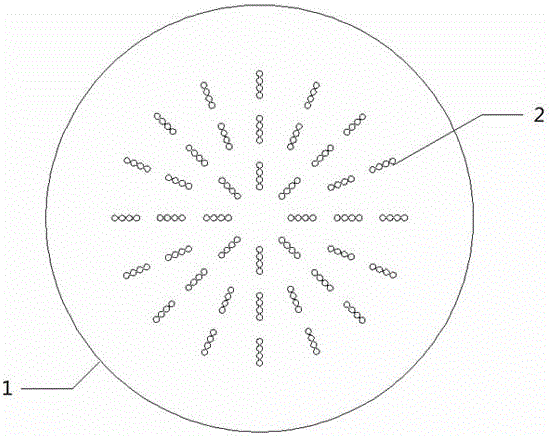

[0025] In this embodiment, after being melted by the screw, the melt is extruded from the spinneret with 40 spinneret holes to form a thin stream of melt, and the spinneret holes are arranged in a centripetal distribution mode; it is cooled and solidified in the cooling zone of the surrounding air blowing. , cluster oiling, drafting and heat setting, to winding forming, and a double-wave linear nylon 6 filament is obtained.

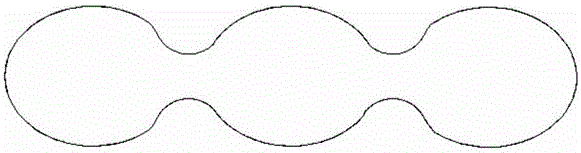

[0026] See attached Figure 4 , which is a schematic diagram of the cross-sectional shape of the double-wavy spinneret hole provided in this embodiment; the spinneret hole is a double-wavy linear flat shape, and along the length direction of the spinneret hole, both sides are symmetrical wavy lines , the wavy line is composed of 4 identical arc-curve connections, and they are connected to each other; the height of the arc curve is 0.045mm; the length of the spinneret hole is 0.90mm, and the aspect ratio of the spinneret hole is 5:1;

[0027] The paramete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com