Cohesive rare earth magnetic powder and preparation equipment thereof

A technology of rare earth magnetic powder and equipment, which is applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of increasing the cost of quick-quenching bonded NdFeB magnetic powder, failing to meet high magnetic energy product, and rusting of magnets, etc., to achieve enhanced Ferromagnetic exchange, low coercive force, solve the effect of easy rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

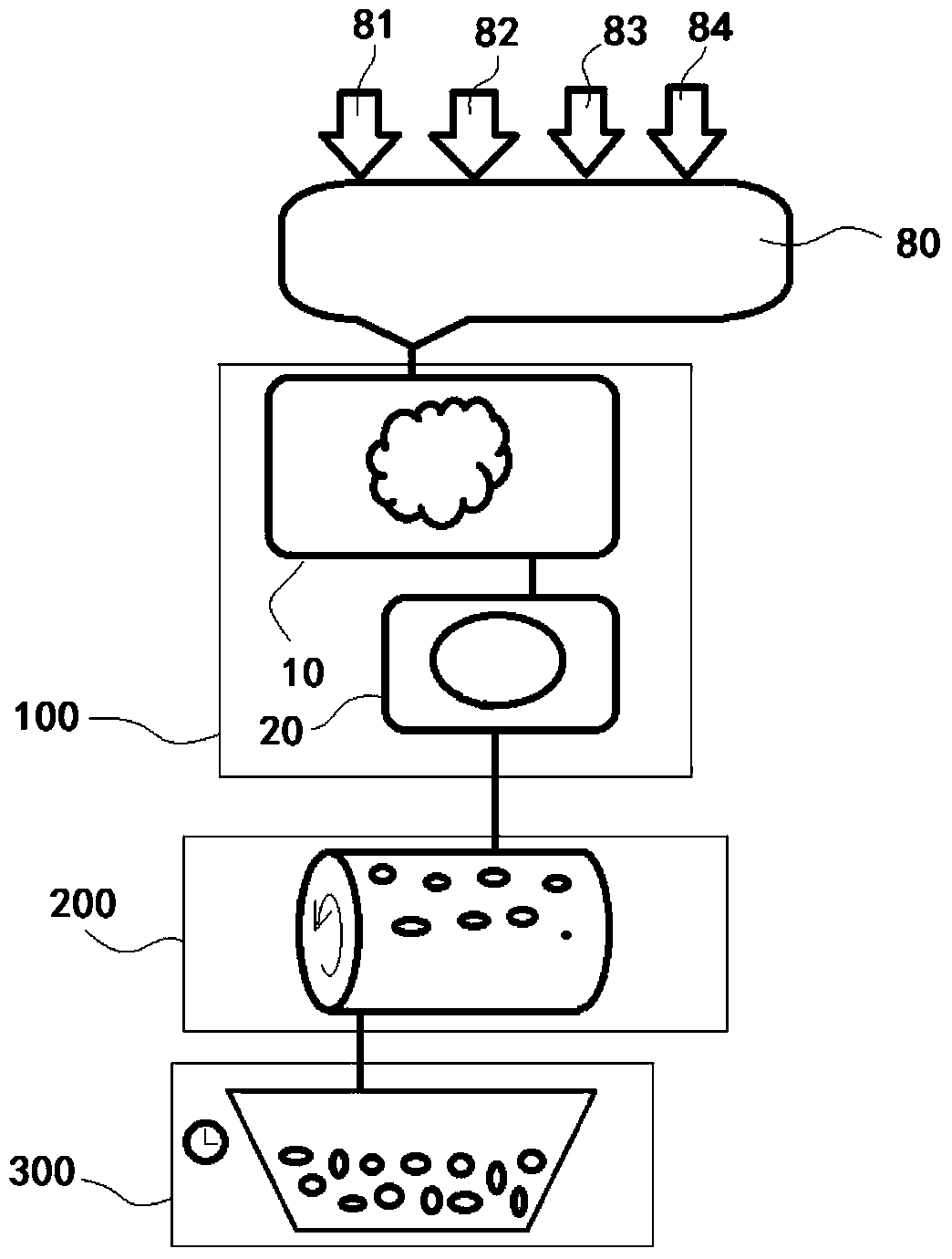

Method used

Image

Examples

Embodiment 1

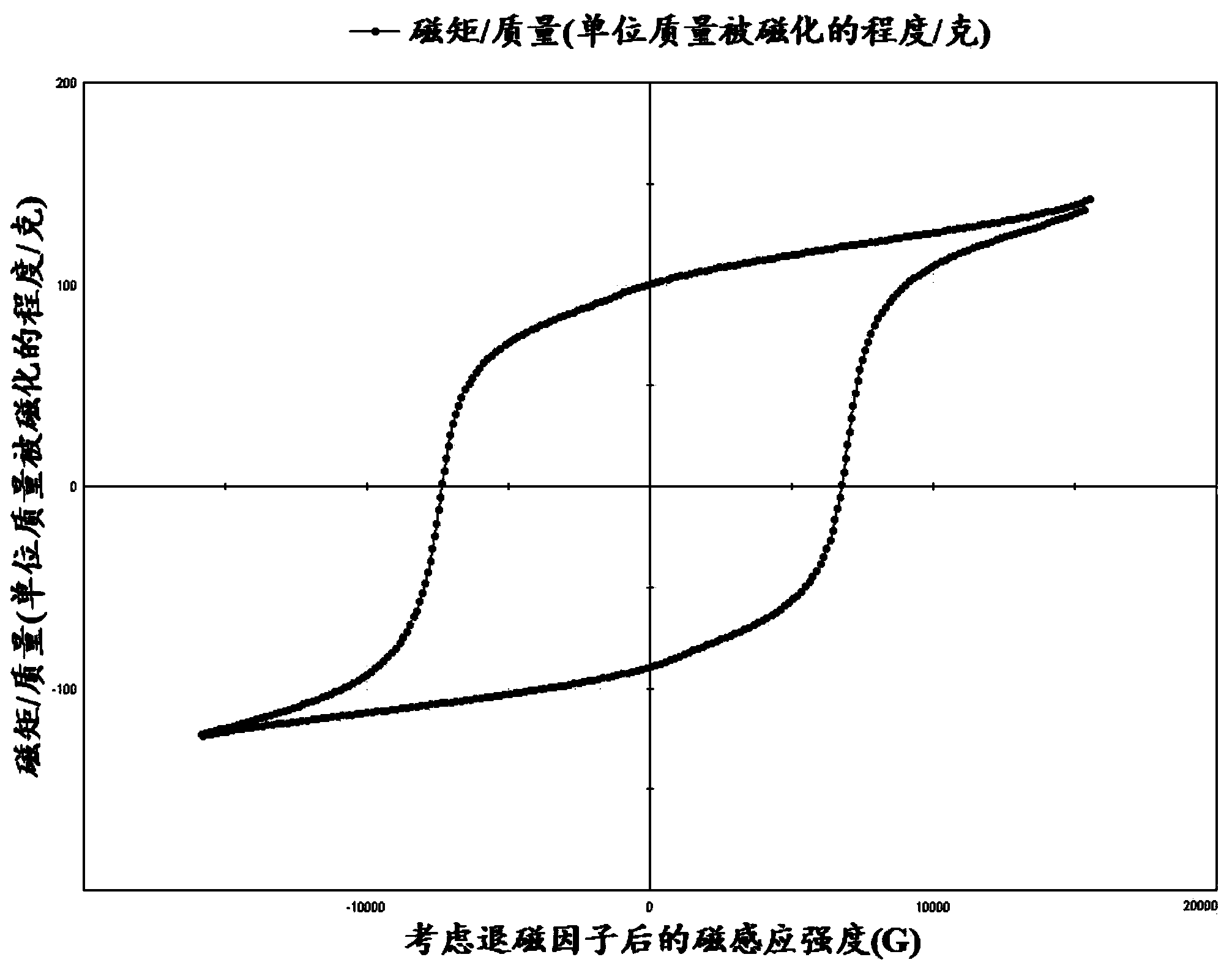

[0045] Proportioning each component according to the above composition formula, the rare earth Nd with a purity of 99.9%, the weight percentage is 24%, the Fe-B alloy (wherein the B content is 19%), the B weight percentage is 2.1%, and the Co weight percentage is 2.0 %, the rest is Fe content. Mix the ingredients evenly, put them into a vacuum melting furnace for smelting under the protection of inert gas argon, and obtain 30 kg of alloy ingots with uniform components after smelting, and perform rapid quenching treatment, 4x10 4 Under the argon pressure of Pa and the rapid quenching speed of 30m / s, the temperature of the rapid quenching furnace is controlled at 1400°C. After obtaining the thin metal strip, it is crushed through a 40-mesh sieve, and crystallized at 700°C for 10 minutes. The prepared sample The magnetic properties were measured by a vibrating sample magnetometer (VSM), and the properties are shown in Table 1.

Embodiment 2

[0047] According to the following formula, the purity is 99.9% Nd, the weight percentage is 24%, the Fe-B alloy (wherein the B content is 19%), the B weight percentage is 2.1%, the Co weight percentage is 2.0%, and the rest is Fe content . Repeat the preparation process for sample 1, 4x10 4 Under the argon pressure of Pa and the rapid quenching speed of 30m / s, the rapid quenching temperature was controlled at 1100°C, crystallized at 700°C for 10 minutes, and the magnetic properties of the prepared samples were measured with a vibrating sample magnetometer (VSM). The performance is shown in Table 1.

[0048] It can be seen from the above examples that the bonded NdFeB magnetic powder obtained under the parameters of Example 1 has high magnetic energy product and low coercive force. Compared with Example 2, when other parameters are the same, changing the quenching temperature directly affects the properties of the magnetic powder. The comparison shows that controlling the que...

Embodiment 3

[0050] According to the following formula, the purity is 99.9% Nd, the weight percentage is 18.6%, the Fe-B alloy (wherein the B content is 19%), the B weight percentage is 2.1%, the Co weight percentage is 2.0%, and the rest is Fe content . Repeat the preparation process for sample 1, 4x10 4 Under the argon pressure of Pa and the rapid quenching speed of 30m / s, the rapid quenching temperature is controlled at 1400°C, and crystallized at a temperature of 700°C for 10 minutes. The prepared sample is measured by a vibrating sample magnetometer (VSM). The magnetic properties are shown in Table 1.

[0051] Comparing Examples 1 and 3, it can be seen that under the same conditions of other parameters, when the weight percentage of rare earth Nd drops from 24% to 18.6%, the main magnetic properties of the magnetic powder also decline significantly. It can be known that the content of rare earth Nd is a major factor affecting the performance of magnetic powder. One of the factors, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap