Sliding type friction nanometer generating set

A generator set, sliding technology, applied in the direction of friction generators, etc., can solve the problems of large size, complex structure, and inability to use power supply components of microelectronic devices, etc., and achieve the effects of small size, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

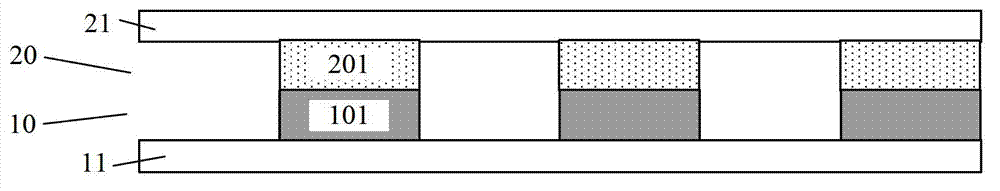

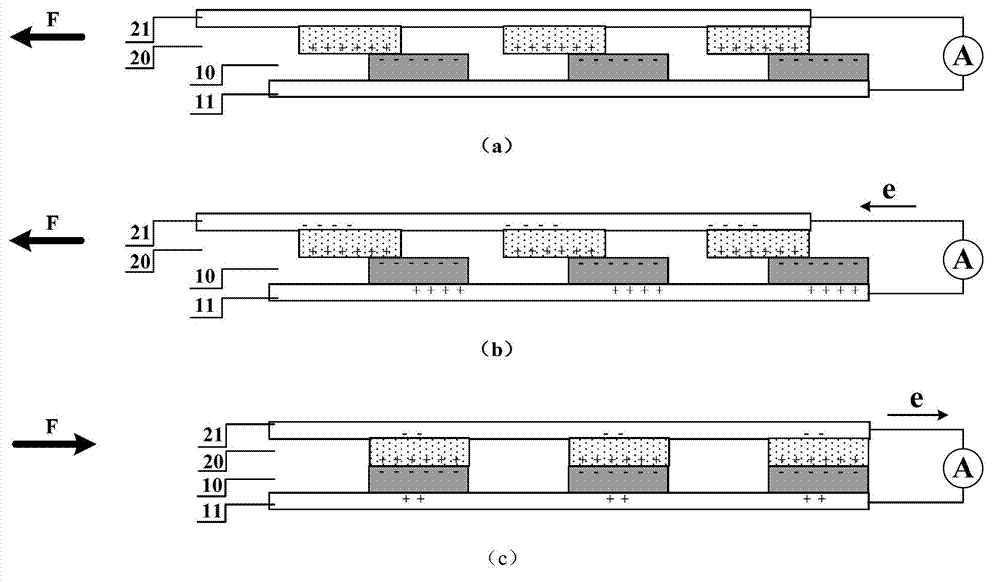

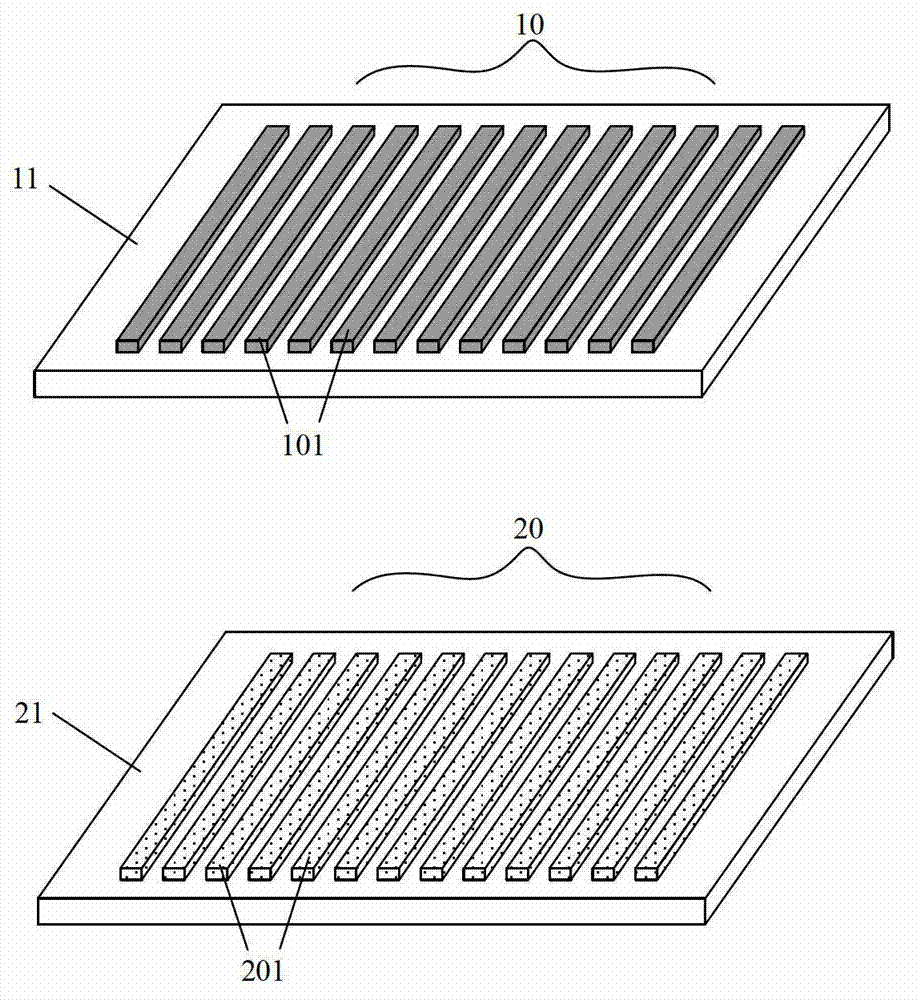

[0098] The first conductive element is a metal copper sheet with a thickness of 1mm and a size of 5cm×6cm. The second conductive element is a metal aluminum sheet with the same size. The material of the first friction unit is Teflon (polytetrafluoroethylene) film. The material of the two friction units is polyethylene terephthalate (PET). Polytetrafluoroethylene and polyethylene terephthalate have extremely negative and extremely positive polarities, respectively, in the triboelectric series. Teflon is made into a strip film structure with length, width and height of 5cm, 0.5cm and 0.2cm respectively, and according to image 3 distributed on the copper sheet at intervals of 0.5 cm. Polyethylene terephthalate is made into a strip film structure with a length, width and height of 5cm, 0.5cm and 0.2cm, and is also distributed on the aluminum sheet at an interval of 0.5cm.

[0099] After the wires are drawn out on the metal aluminum sheet and the metal copper sheet, the polyethy...

Embodiment 2

[0101] This embodiment is basically the same as Embodiment 1, the only difference is that: a silicon wafer with a thickness of 600 μm is used as the first friction unit material, and a layer of photoresist is coated on the surface of the silicon wafer by rotation A square window array with a side length of micron or sub-micron level is formed on the glue, and the silicon wafer after photolithography is chemically etched with hot potassium hydroxide to form a pyramid-shaped concave structure array at the window. Then divide it into small pieces with a length of 2cm and a width of 2cm, and arrange them on the surface of the first conductive element in a checkerboard shape; with polydimethylsiloxane (PDMS) as the second friction unit, it is also divided into 2cm×2cm The small pieces are arranged on the surface of the second conductive element in a manner corresponding to the silicon chip. When the silicon wafer and PDMS are in contact with each other under the action of external ...

Embodiment 3

[0103] This embodiment is basically the same as Embodiment 2, except that the nanowire array is further prepared by inductively coupled plasma etching on the PDMS surface. Put the PDMS film into an inductively coupled plasma etching machine, etch the side on which gold is deposited, and pass O 2 , Ar and CF 4 Gas, the flow rate is controlled at 10sccm, 15sccm and 30sccm respectively, the pressure is controlled at 15mTorr, the working temperature is controlled at 55°C, the plasma is generated with a power of 400 watts, and the plasma is accelerated with a power of 100 watts for about 5 minutes of etching , a PDMS nanorod array with a length of approximately 1.5 microns substantially perpendicular to the film layer was obtained. The contact area between the PDMS film with a microstructure on the surface and the silicon wafer is further increased, and the output performance of the generator is further improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com