Supported manganese dioxide adsorbent and method for treating aniline waste water through same

A technology for manganese dioxide and aniline wastewater, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effect of less usage, good removal effect and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

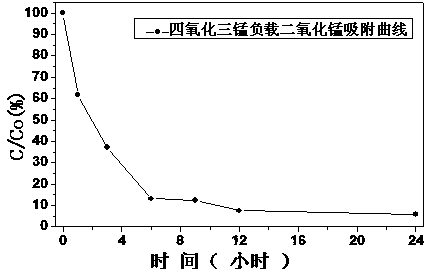

Image

Examples

Embodiment 1

[0039] Weigh 0.674g of potassium permanganate solid and dissolve it in 40mL of deionized water, add 2mL of ethylene glycol under magnetic stirring, and the solution is uniform after stirring for 20 minutes. It was added into a 100mL autoclave and heated at 160°C for 10 hours. After the autoclave was cooled to room temperature, the brown powdery solid was separated by centrifugation (7000rpm, 10min), and the impurities in the product were washed with water, ethanol, and water in sequence. Vacuum drying in a vacuum oven at 80°C for 5 hours to obtain submicron octahedral powder of trimanganese tetraoxide with a particle size of 100-800nm.

[0040] Disperse 0.1 g of manganese tetraoxide powder obtained by ultrasonic method into 50 mL of deionized water, add 0.25 g of potassium permanganate and 0.8 mmol of 37% hydrochloric acid, and stir evenly. Under the condition of magnetic stirring, seal and heat in an oil bath at 80° C. for 5 hours. After the container is cooled to room temp...

Embodiment 2

[0043]Weigh 0.674g of potassium permanganate solid and dissolve it in 40mL of deionized water, add 2mL of ethylene glycol under magnetic stirring, and stir for 40 minutes to make the solution uniform. Pour it into a 100mL autoclave and heat it at 160°C for 10 hours. After the autoclave was cooled to room temperature, the brown powder was separated by centrifugation (10000rpm, 5min), and the impurities in the product were washed with water, water and ethanol in sequence. Vacuum dry in a vacuum oven at 70°C for 8 hours to obtain submicron octahedral powder of trimanganese tetraoxide with a particle size of 100-800nm.

[0044] Disperse the obtained 0.1g manganese tetraoxide powder into 50mL deionized water by ultrasonic method, add 0.25g potassium permanganate and 1.0mmol37% hydrochloric acid, stir evenly, and heat it in a sealed oil bath at 95°C for 23 hours under magnetic stirring . After the container is cooled to room temperature, centrifuge the solid-liquid mixture at 10,0...

Embodiment 3

[0047] Weigh 0.606g of sodium permanganate solid and dissolve it in 30mL of deionized water, add 1.5mL of ethylene glycol under magnetic stirring, and stir for 30 minutes to make the solution uniform. The mixture was poured into a 50mL autoclave, and heated at 160°C for 10 hours. After the autoclave was cooled to room temperature, the brown powder was separated by centrifugation (8000rpm, 8min), and the impurities in the product were washed with water, water and ethanol in sequence. Vacuum-dry in a vacuum oven at 50°C for 12 hours to obtain octahedral manganese tetraoxide submicron powder with a particle size of 100-800nm.

[0048] Disperse 0.1 g of manganese tetraoxide powder obtained by ultrasonic method into 50 mL of deionized water, add 0.25 g of sodium permanganate and 1.5 mmol of 37% hydrochloric acid, stir evenly, and heat in a sealed oil bath at 105°C for 8 hours. After the container is cooled to room temperature, centrifuge the solid-liquid mixture at a speed of 8000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com