Method for separating potassium feldspar and soda feldspar from potassium-soda feldspar ore

A technology of potassium feldspar and albite, which is applied in the field of separating potassium feldspar and albite, which can solve the problems of low concentrate grade and yield, regardless of concentrate grade or yield, and achieve rapid removal of impurities , low production cost and high product recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. This embodiment is only to illustrate the present invention more clearly, rather than limit the present invention.

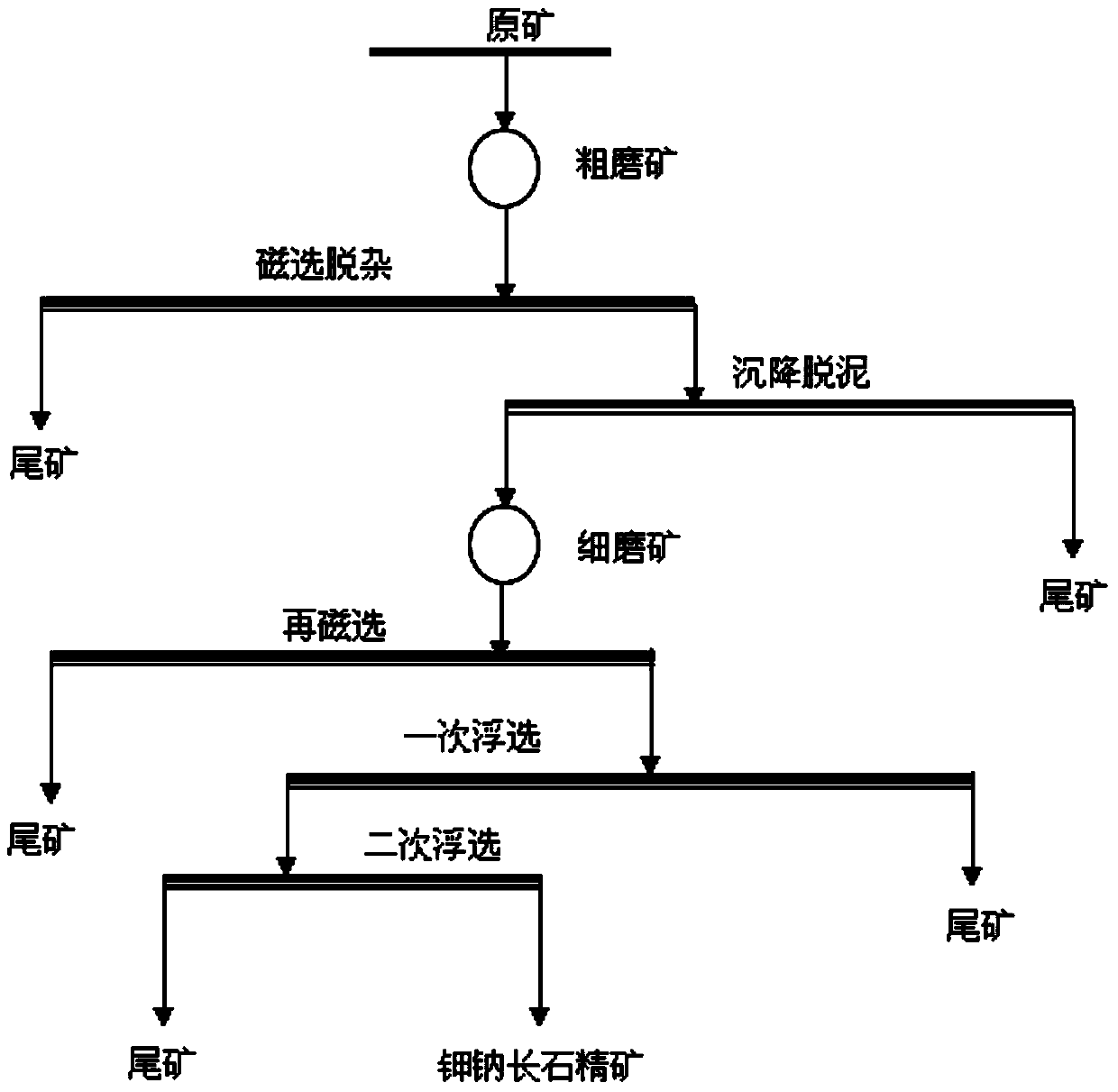

[0020] Below adopt mineral processing technology provided by the present invention (attachment figure 1 ) to beneficiate the following raw ore:

[0021] A low-grade potassium-sodium feldspar mine in Guangxi, my country, the ore mainly contains albite, potassium feldspar, mica minerals, quartz, calcite, and a small amount of hematite. Analysis of main elements: K 2 O, 5.37; Na 2 O, 4.45; Fe 2 o 3 , 1.25; TiO, 0.34.

[0022] The specific process steps are:

[0023] (1) Coarse grinding: Crushing and grinding the raw ore of potassium albite feldspar, and controlling the particle size to -0.045, accounting for 70%;

[0024] (2) Magnetic separation and impurity removal: use a magnetic separator for magnetic separation, the flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com