Method for processing graphene superlattice nano-structure with atomic force microscope

An atomic force microscope and nanostructure technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of difficult processing, reduce the electrical properties of devices, and roughness of graphene, and achieve the effect of simple processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

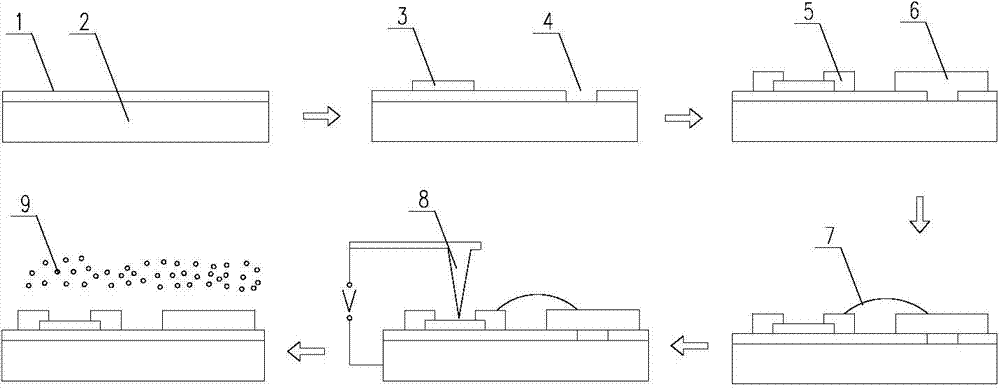

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Such as figure 1 As shown, in this embodiment, the present application provides a method for processing graphene superlattice nanostructures using an atomic force microscope, which includes: Step A: using the needle tip 8 of the atomic force microscope to apply a pulse voltage to the graphene 3 artificial vacancy defects.

[0024] Step B: using hydrogen-containing plasma 9 to anisotropically etch the graphene 3 .

[0025] The method of adding pulse voltage to the tip of the atomic force microscope is used to artificially introduce periodic vacancy defects, the smallest period of which can reach 50nm, and then processed by hydrogen plasma9 to make the boundary of the cavity form an atomically smooth zigzag (serrated) boundary, At the same time, the size of graphene 3 nanoribbons can be accur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com