Lead-free piezoelectric potassium sodium niobate optoelectronic multifunctional material and preparation method thereof

A potassium sodium niobate and lead-free piezoelectric technology, which is applied to circuits, electrical components, semiconductor devices, etc., to achieve the effects of improved luminous performance, universal and simple method, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

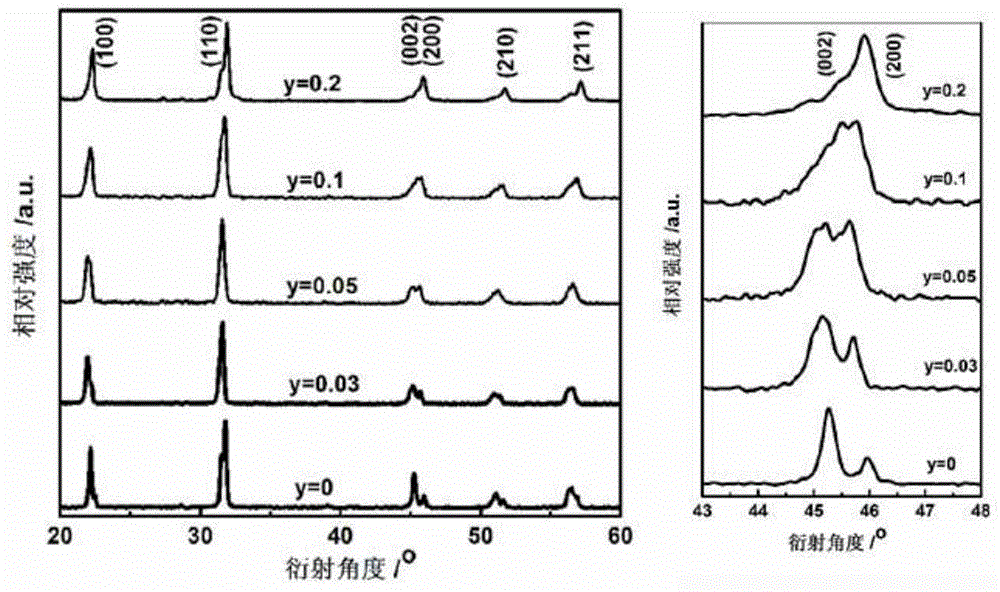

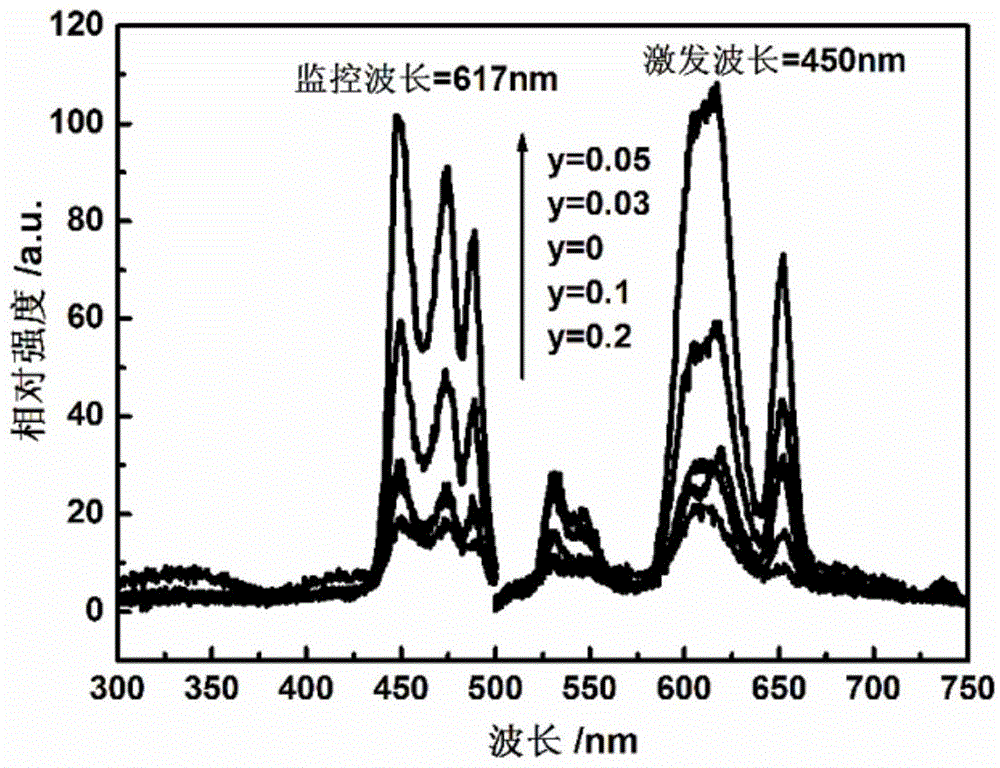

[0033] Prepared by traditional solid-state reaction sintering process (K 0.5 Na 0.5 ) 1-y-x m y ln x Nb 1-y Ti y o 3 Ceramics, wherein Ln is selected from Pr, M is selected from Ca, wherein x=0.002, y=0.05, that is (K 0.5 Na 0.5 ) 0.948 Ca 0.05 PR 0.002 Nb 0.95 Ti 0.05 o 3 . Metal carbonate or metal oxide as raw material, K 2 CO 3 (99%), Na 2 CO 3 (98%), Nb 2 o 5 (99.5%), P 6 o 11 (99%), CaCO 3 (99.99%), TiO 2 (99.6%), and the raw materials were fully dried before weighing.

[0034] (1) Weigh 7.543 grams of Na 2 CO 3 , 9.925 g K 2 CO 3 , 1.503 g CaCO 3 , 37.911 g Nb 2 o 5 , 1.210 g TiO 2

[0035] and 0.102 g P 6 o 11 As raw materials, put them into a polytetrafluoroethylene ball mill jar after mixing, use ethanol as the grinding medium, and use ZrO 2 As a grinding ball, wet ball milling for 24 hours, slurry filtration, washing, drying, and sieving to obtain a uniformly mixed batch;

Embodiment 2

[0040] Preparation (K 0.5 Na 0.5 ) 1-y-x m y ln x Nb 1-y Ti y o 3 , wherein Ln is selected from Pr, and M is selected from Ca, wherein x=0.002, y=0.03, 0.1, 0.2; namely (K 0.5 Na 0.5 ) 0.998-y Ca y PR 0.002 Nb 1-y Ti y o 3 :(K 0.5 Na 0.5 ) 0.968 Ca0.03 PR 0.002 Nb 0.97 Ti 0.03 o 3 , (K 0.5 Na 0.5 ) 0.898 Ca 0.1 PR 0.002 Nb 0.9 Ti 0.1 o 3 , (K 0.5 Na 0.5 ) 0.798 Ca 0.2 PR 0.002 Nb 0.8 Ti 0.2 o 3 . The selected raw materials were weighed according to the stoichiometric ratio, mixed and put into a polytetrafluoroethylene ball mill tank, with ethanol as the grinding medium and ZrO 2 As a grinding ball, wet ball milling for 24 hours, slurry filtration, washing, drying, and sieving to obtain a uniformly mixed batch; the sieved powder is put into an alumina crucible for pre-calcination, and the pre-calcination temperature is 850 o C,880 o C, 900 o C, keep warm for 6 hours, cool down to room temperature naturally with the furnace, and then carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com