Epoxy resin composition and preparation method thereof

A technology of epoxy resin and novolac epoxy resin, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of increasing PCB processing and manufacturing costs, toughness, peel strength and PCB processability And other problems, to achieve the effect of good peel strength, excellent heat resistance, and meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

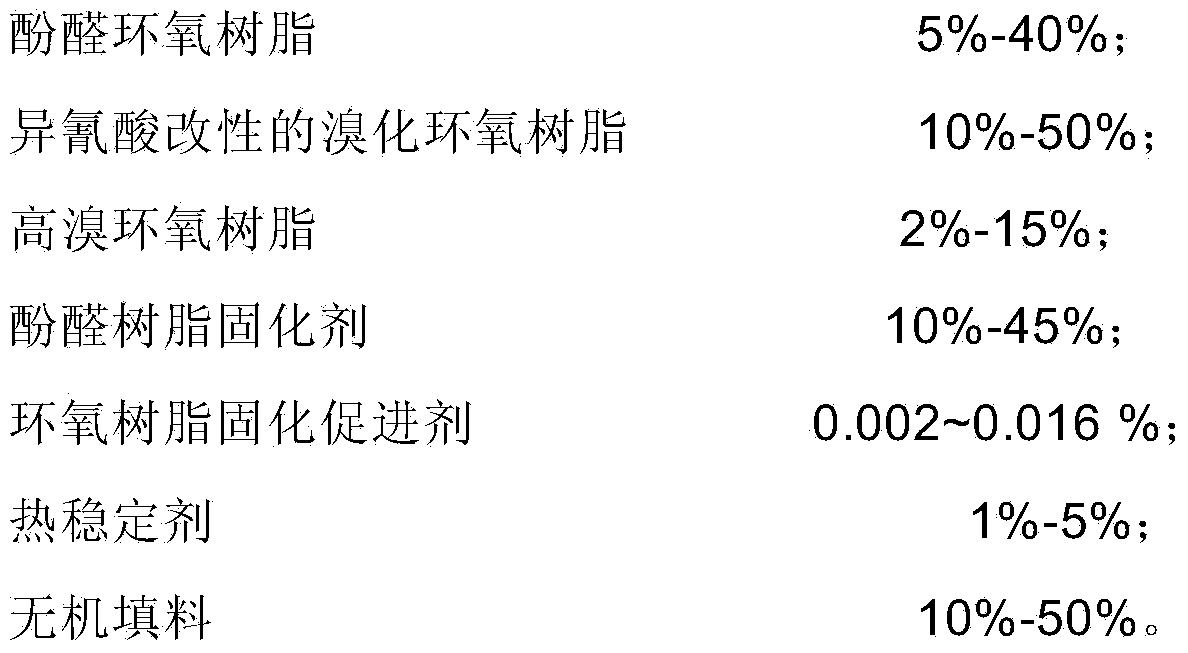

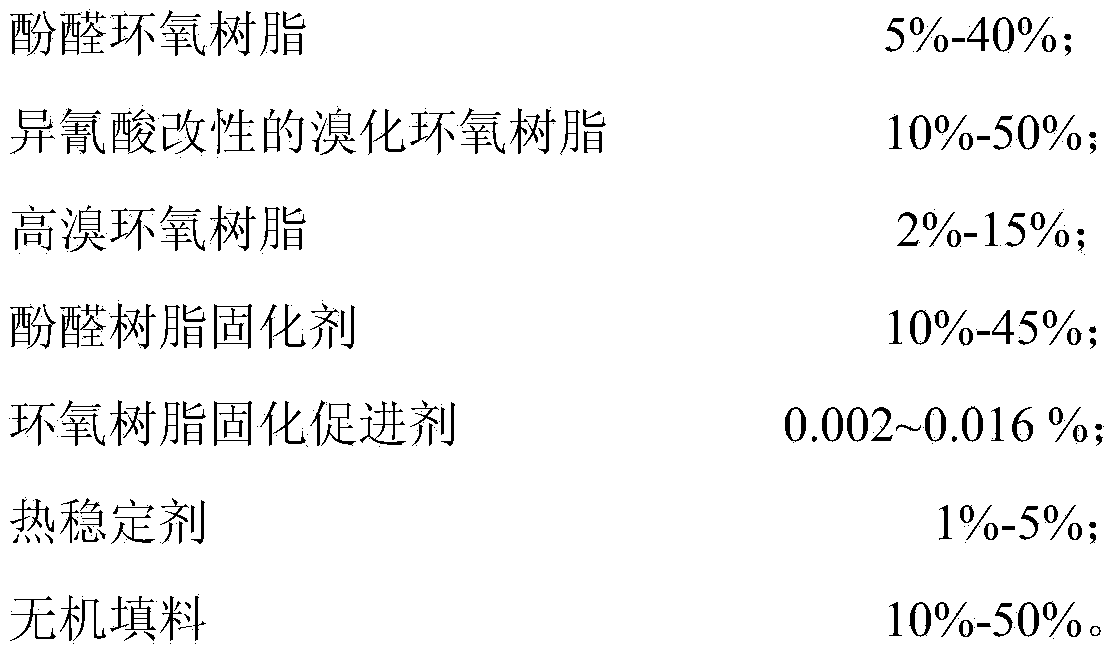

Method used

Image

Examples

Embodiment 1

[0055] 1. The mass percentage of solids in the epoxy resin composition is 66.5%, and the rest are organic solvents (such as propylene glycol methyl ether),

[0056] Among them, the formula of solid matter is shown in the following table (by weight)

[0057] raw material Solid weight (g) Novolac epoxy resin 20 Isocyanate Modified Brominated Epoxy Resin 15 High Brominated Epoxy Resin 8 Phenolic resin curing agent 23 2-Ethyl-4-methylimidazole (2E4MZ) 0.05 Heat stabilizers 2.5 Aluminum hydroxide 10 silica 20

[0058] 2. The preparation method of epoxy resin composition:

[0059] (1) Add 49 grams of organic solvent propylene glycol methyl ether into the stirring tank according to the above weight, turn on the stirrer at a speed of 600 rpm, and continue stirring for 30 minutes;

[0060] (2) Add novolac epoxy resin, isocyanic acid modified brominated epoxy resin, high bromine epoxy resin, phenolic resin and heat stabili...

Embodiment 2

[0068] 1. The mass percentage of solids in the epoxy resin composition is 65%, and the rest are organic solvents (such as propylene glycol methyl ether),

[0069] Among them, the formula of solid matter is shown in the following table (by weight)

[0070] raw material Solid weight (g) Novolac epoxy resin 25 Isocyanate Modified Brominated Epoxy Resin 14 High Brominated Epoxy Resin 6 Phenolic resin curing agent 22 2-Ethyl-4-methylimidazole (2E4MZ) 0.04 Heat stabilizers 2 Aluminum hydroxide 7 silica 22

[0071] 2. The preparation method of epoxy resin composition:

[0072] (1) Add 52 grams of organic solvent propylene glycol methyl ether into the stirring tank according to the above weight, turn on the stirrer, rotate at 600 rpm, and continue stirring for 30 minutes;

[0073] (2) Add novolac epoxy resin, isocyanic acid modified brominated epoxy resin, high bromine epoxy resin, phenolic resin and heat stabilizer in o...

Embodiment 3

[0081] 1. The mass percentage of solids in the epoxy resin composition is 62.3%, and the rest are organic solvents (such as propylene glycol methyl ether),

[0082] Among them, the formula of solid matter is shown in the following table (by weight)

[0083] raw material Solid weight (g) Novolac epoxy resin 30 Isocyanate Modified Brominated Epoxy Resin 12 High Brominated Epoxy Resin 10 Phenolic resin curing agent 27 2-Ethyl-4-methylimidazole (2E4MZ) 0.07 Heat stabilizers 1.3 Aluminum hydroxide 13 silica 17

[0084] 2. The preparation method of epoxy resin composition:

[0085] (1) Add 66 grams of organic solvent propylene glycol methyl ether into the stirring tank according to the above weight, turn on the stirrer at a speed of 600 rpm, and continue stirring for 30 minutes;

[0086] (2) Add novolac epoxy resin, isocyanic acid modified brominated epoxy resin, high bromine epoxy resin, phenolic resin and heat stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com