Thermally conductive graphite patch for adhesive tape and preparation method thereof

A heat-conducting graphite and patch technology, applied in chemical instruments and methods, modification and application through conduction and heat transfer, can solve problems such as poor reliability, overheating of tape, uneven heat dissipation, etc., to improve flatness and flexibility, Improve the biaxial tensile properties and overcome the effect of excessive heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

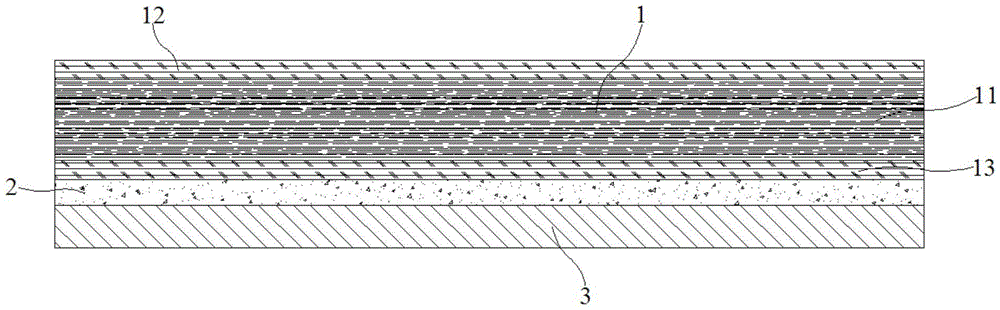

[0047] Embodiment: a kind of thermally conductive graphite patch for adhesive tape, the surface of the thermally conductive graphite patch 1 is coated with a thermally conductive adhesive layer 2, and the surface of the thermally conductive adhesive layer 2 and the opposite side of the thermally conductive graphite patch 1 is pasted with a Release material layer 3; it is characterized in that: the heat-conducting graphite patch 1 is made up of polyimide film 11, first coating layer 12 and second coating layer 13, and described first coating layer 12, the second coating layer The second coating layer 13 is respectively located on the upper and lower surfaces of the polyimide film 11;

[0048] Both the first coating layer and the second coating layer are composed of the following components by weight:

[0049] Table 1

[0050]

Example 1

Example 2

Example 3

Example 4

Example 5

Benzophenone Tetradianhydride

21

22

22.5

25

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com