patch

A technology of patch and methyl, which is applied in the field of patch, and can solve the problems such as the storage stability of rivastigmine that has not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

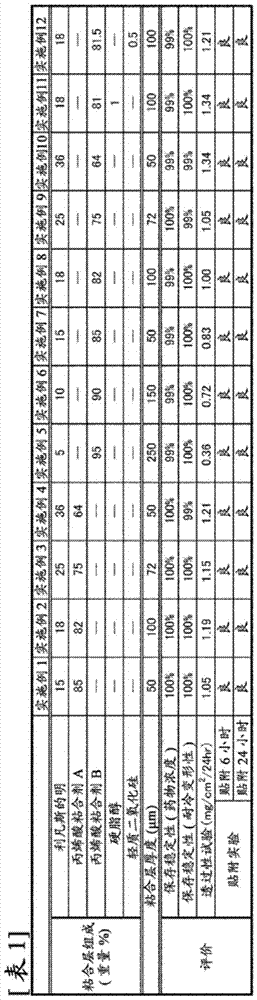

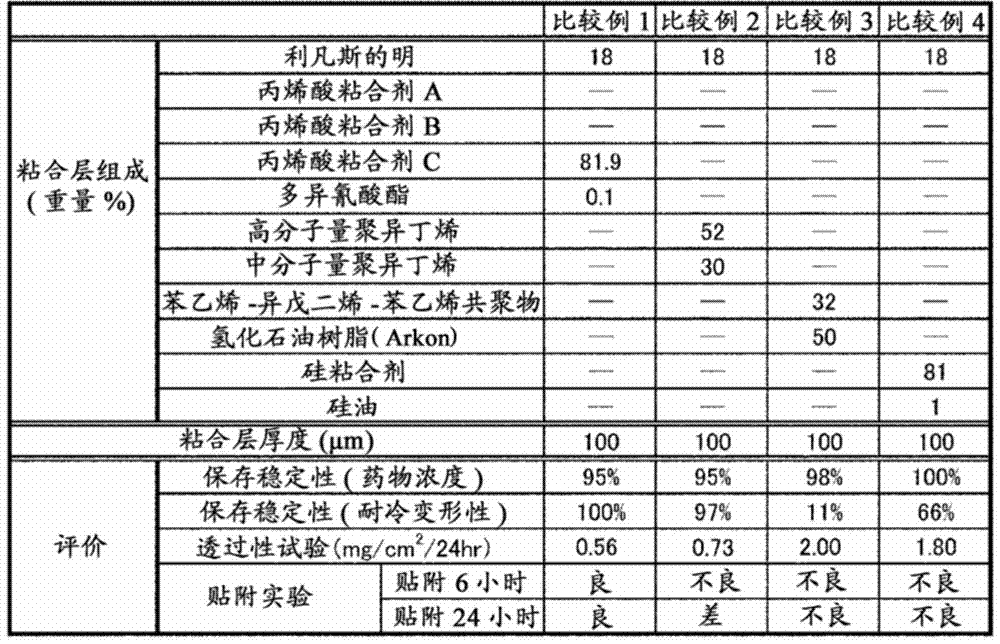

[0085] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples.

[0086] (Preparation of Acrylic Adhesive A)

[0087] Acrylic Adhesive A was prepared as follows. The reaction liquid is supplied to a polymerization reactor of 40 liters, and the reaction liquid is composed of 50 parts by weight of ethyl acetate and 13 parts by weight of lauryl methacrylate, 78 parts by weight of 2-ethylhexyl methacrylate and 2 parts by weight of acrylic acid. - A monomer composition of 9 parts by weight of ethylhexyl ester. Then, the inside of the polymerization reactor was adjusted to a nitrogen atmosphere of 80°C. Then, a polymerization initiator solution obtained by dissolving 0.5 parts by weight of benzoyl peroxide in 50 parts by weight of cyclohexane was added to the above-mentioned reaction solution over 24 hours, and at the same time, the above-mentioned monomers were subjected to a copolymerization reaction. After the po...

Embodiment (1~12

[0093] Mix rivastigmine, acrylic binder solution A, acrylic binder solution B, stearyl alcohol (manufactured by Advanced Alcohol Industry Co., Ltd.), and light silica (manufactured by Japan Aerosil Co., Ltd., A200) as a solvent Ethyl acetate was added so that the concentration of the solid content became 25% by weight, and then mixed until uniform to prepare an adhesive layer solution.

[0094] Then, a release sheet was prepared which had been subjected to a release treatment by coating polysiloxane on one side of a release base material having a thickness of 38 μm and formed of a polyethylene terephthalate film. The adhesive layer solution was applied on the release-treated surface of the release sheet, and dried at 80° C. for 30 minutes, thereby producing a film having the thickness shown in Table 1 on the release-treated surface of the release sheet. A laminate of adhesive layers. It should be noted that the content of each component in the adhesive layer is as shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com