Synthetic method of sliver/ferroferric oxide/silicon dioxide/titanium dioxide four-layer nuclear shell structure and application thereof

A technology of ferroferric oxide and core-shell structure, applied in the direction of metal/metal oxide/metal hydroxide catalyst, alkali metal oxide/hydroxide, chemical instruments and methods, etc., can solve the problem of small adsorption capacity, specific The surface is small, the adsorption and catalytic performance are not very good, etc., to achieve good adsorption characteristics, improve catalytic activity, and enhance the effect of adsorption and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] The purposes of the above-mentioned silver / ferric oxide / silicon dioxide / titanium dioxide four-layer core-shell structure of the present invention, its preferred embodiment is:

[0039] The four-layer core-shell structure is used for the removal of organic pollutants and / or heavy metal pollutants.

[0040] After the four-layer core-shell structure removes organic pollutants and / or heavy metal pollutants, the catalyst powder used in the removal process is separated from the solution by magnetic separation, so as to facilitate the recycling of catalyst materials.

[0041] The present invention adopts technologies such as hydrothermal, sol-gel, and self-organized growth to prepare silver / ferric oxide / silicon dioxide / titanium dioxide core-shell structure, and silver has a strong plasma enhancement effect, which improves catalytic activity; magnetic nanoparticles have Superparamagnetic, so as to facilitate the recycling of catalyst materials; the outermost layer of titanium d...

specific Embodiment

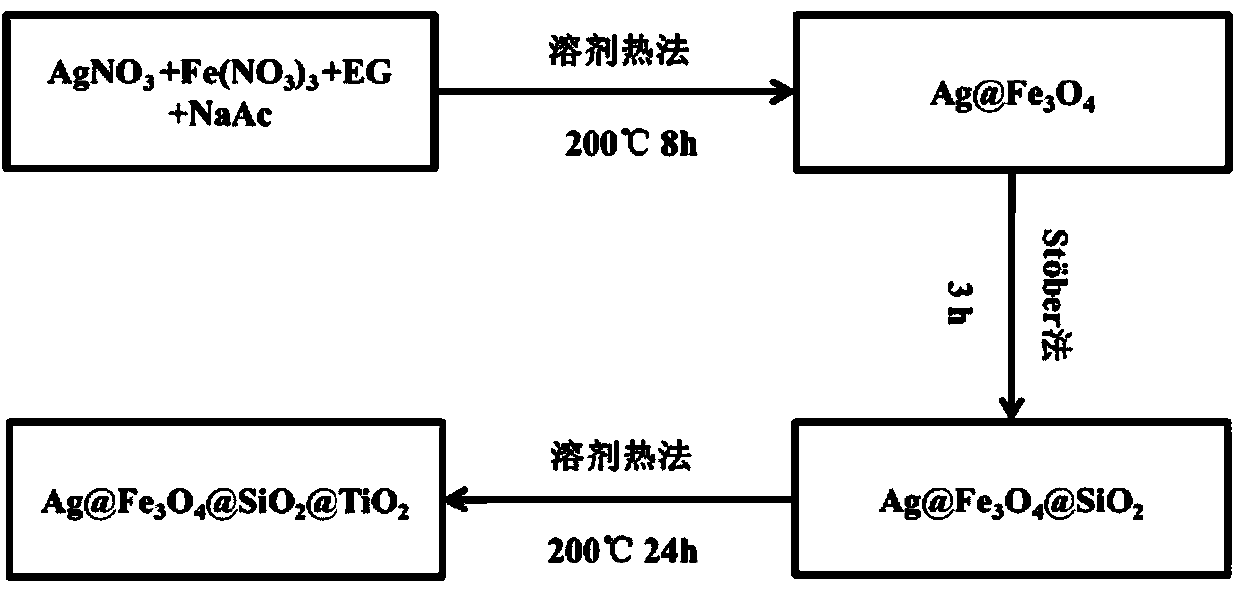

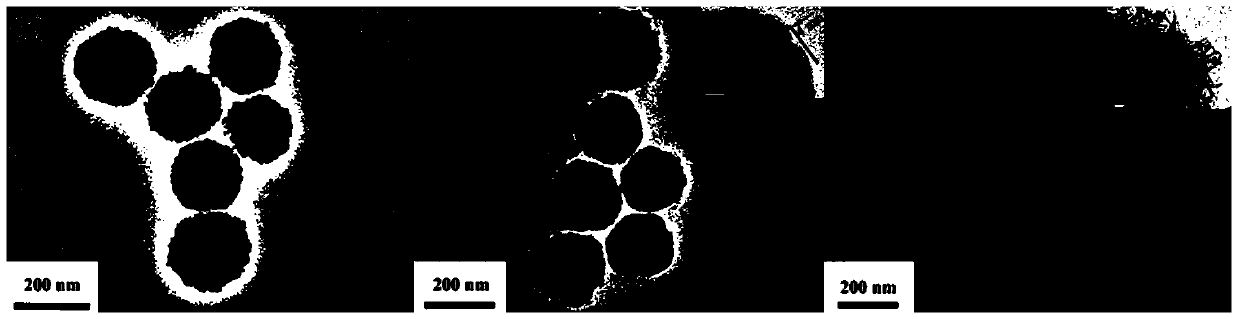

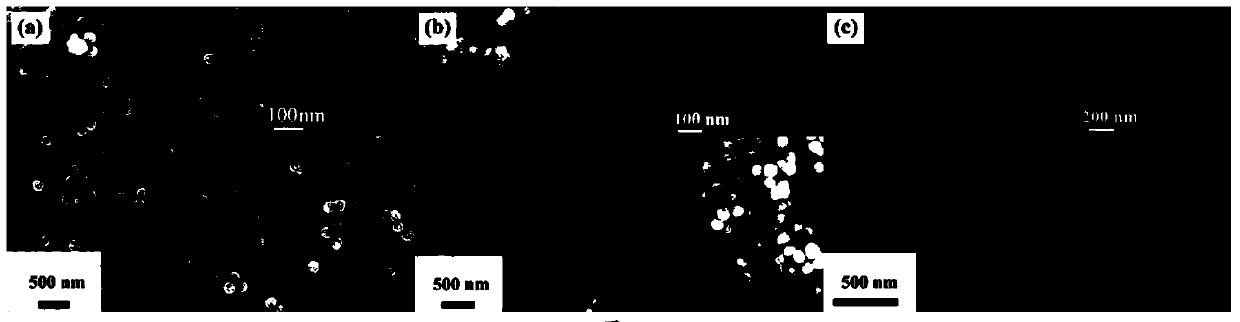

[0042] Such as figure 1 As shown, the Ag / Fe3O4 core-shell structure (AgFe 3o 4 ),Reuse Silver / ferric oxide / silicon dioxide three-layer structure (AgFe 3 o 4 SiO 2 ), and then use the solvothermal method to coat a layer of burr-like titanium oxide composed of nanosheets on the surface of the above-mentioned core-shell structure to obtain silver / ferric oxide / silicon dioxide / titanium dioxide (AgFe 3 o 4 SiO 2 TiO 2 ) four-layer core-shell structure.

[0043] In the first step, ferric nitrate, sodium acetate, silver nitrate and ethylene glycol are mixed, then magnetically stirred at room temperature for 0.5-1h, and the mixed solution is transferred to a stainless steel reaction kettle with a Teflon substrate. Heat at 200 degrees Celsius for 8 hours. Wherein the molar ratio of ferric nitrate, sodium acetate, and silver nitrate is 400:3500:59, and the content of ethylene glycol is excessive. After the reaction is completed, the mixed solution is washed with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com