Synthetic method of copper nano-particles of different shapes

A technology of copper nanoparticles and synthesis methods, applied in the field of nano-metal materials, can solve the problems of obtaining copper nanoparticles, complex preparation process, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

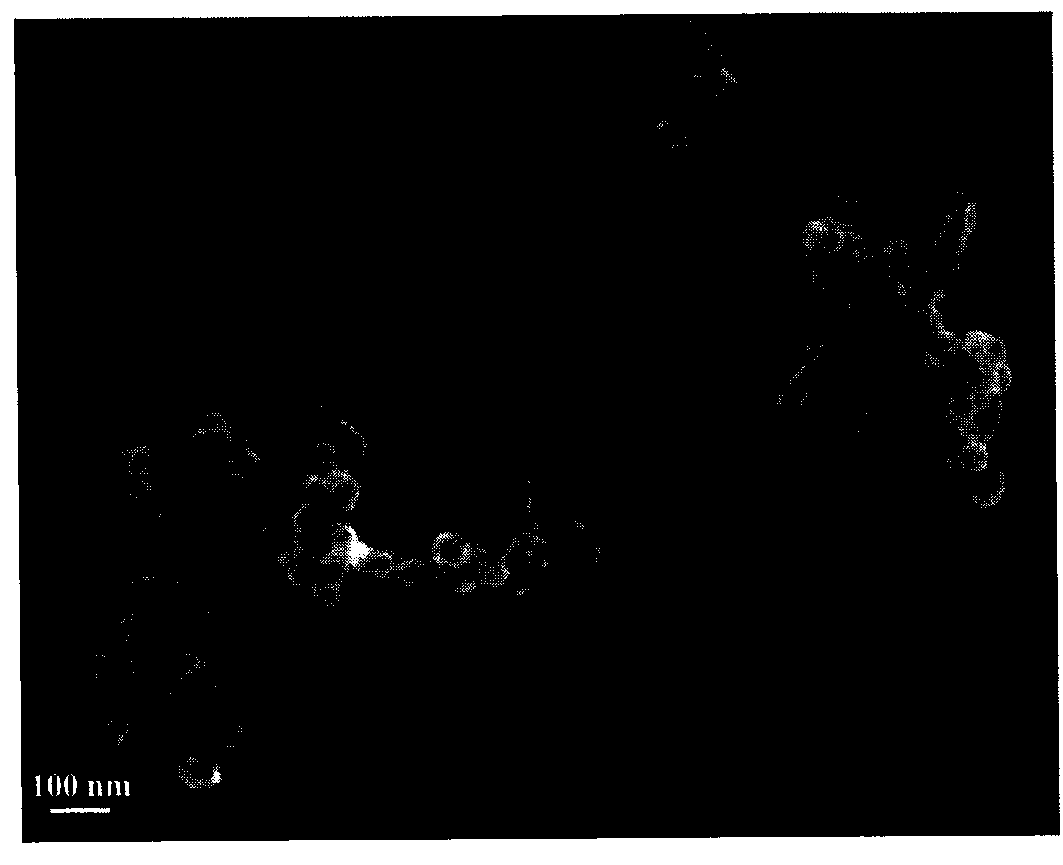

Embodiment 1

[0020] Dissolve the copper salt compound cupric chloride dihydrate in distilled water, prepare 50ml cupric chloride dihydrate solution with a concentration of 0.2M, and ultrasonicate for 5 minutes, place in an oil bath and heat to a temperature of 60°C for stirring;

[0021] Dissolve L-ascorbic acid in distilled water to prepare 50ml of 0.7M L-ascorbic acid solution, add the configured L-ascorbic acid solution dropwise to the configured copper chloride dihydrate solution under stirring, at a temperature of 60°C, After the L-ascorbic acid solution was added dropwise, the stirring was continued for 14 hours to obtain a mixed solution;

[0022] The mixture was centrifuged at 11500rpm for 10 minutes, and the obtained precipitate was washed 4 times with absolute ethanol, and the washed product was dried in a vacuum oven at a temperature of 30°C for 12 hours, and the dark brown dry product obtained was copper nanoparticles .

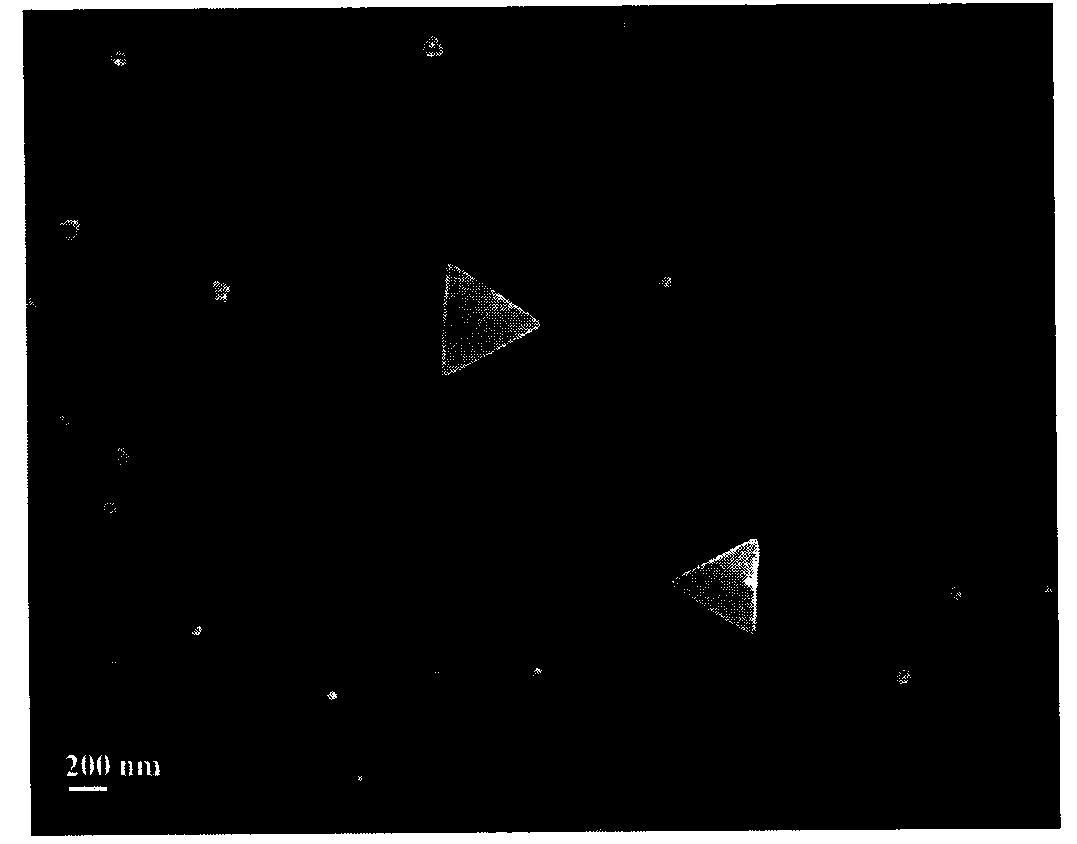

Embodiment 2

[0024] Dissolve the copper salt compound copper sulfate in distilled water, prepare 50ml of copper sulfate solution with a concentration of 0.2M, ultrasonicate for 5 minutes, place in an oil bath, heat to a temperature of 75°C, and stir;

[0025] Dissolve L-ascorbic acid in distilled water to prepare 50ml 0.9M L-ascorbic acid solution, add the prepared L-ascorbic acid solution dropwise to the prepared copper sulfate solution under stirring, and wait for the L- After the ascorbic acid solution was added dropwise, the stirring was continued for 14 hours to obtain a mixed solution;

[0026] The mixture was centrifuged at 11,500 rpm for 10 minutes, and the obtained precipitate was washed 4 times with absolute ethanol, and the washed product was dried in a vacuum oven at 30° C. for 12 hours, and the obtained black-brown dried product was copper nanoparticles.

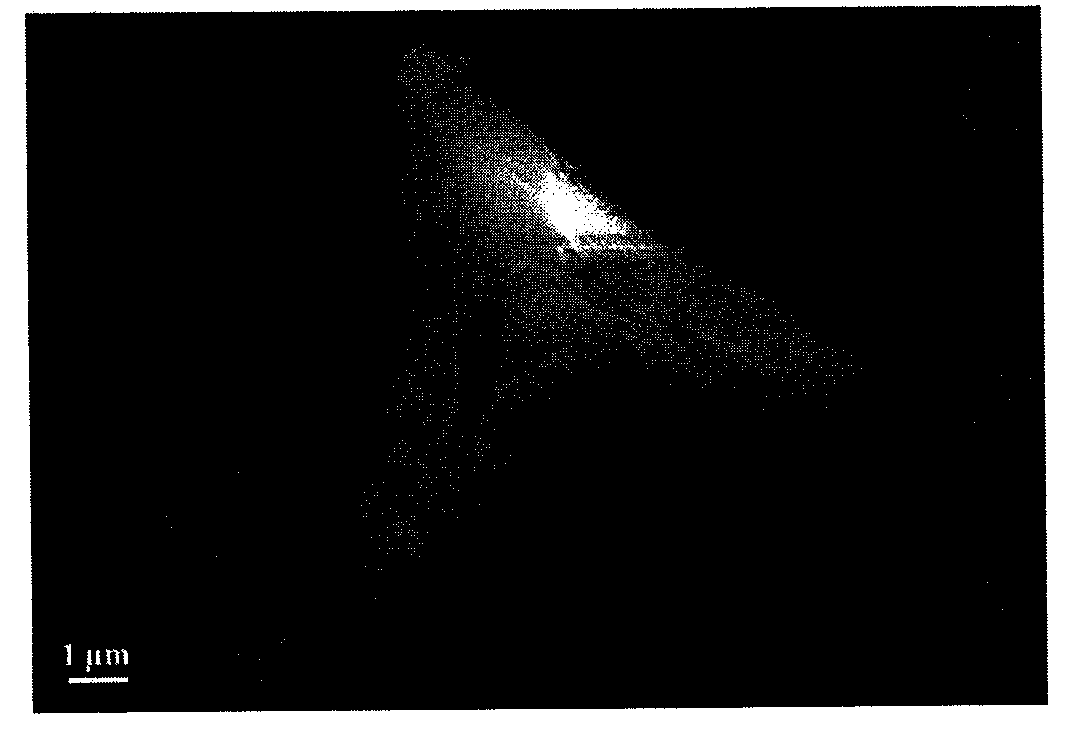

Embodiment 3

[0028] Dissolve the copper salt compound cupric chloride dihydrate in distilled water, prepare 50 ml of cupric chloride dihydrate solution with a concentration of 0.2M, and ultrasonicate for 5 minutes, place it in an oil bath, heat to a temperature of 85°C, and stir;

[0029] Dissolve L-ascorbic acid in distilled water to prepare 50ml of 1.1M L-ascorbic acid solution, add the configured L-ascorbic acid solution dropwise to the configured copper sulfate solution under stirring, and wait for L- After the ascorbic acid solution was added dropwise, the stirring was continued for 14 hours to obtain a mixed solution;

[0030] The mixture was centrifuged at 11,500 rpm for 10 minutes, the obtained precipitate was washed 4 times with absolute ethanol, and the washed product was dried in a vacuum oven at a temperature of 30°C for 12 hours, and the obtained black-brown dried product was copper nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com