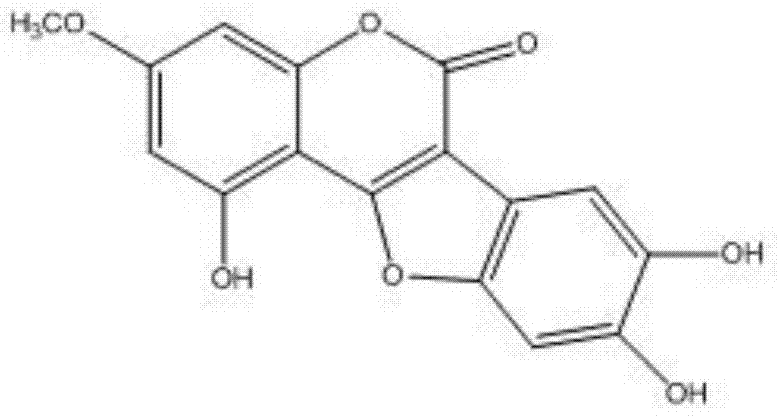

Preparation method of high-purity wedelolactone

A high-purity technology for wedelide, which is applied in the field of natural medicinal chemistry, can solve the problem of low purity of norwedelide, and achieve the effects of large separation volume, low pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Crush the raw material of Eclipta chinensis, weigh 2kg, add 10L50% methanol solution for ultrasonic extraction for 30 minutes each time, extract 3 times, extract the extract under reduced pressure to 1000ml, add an equal volume of water-saturated ethyl acetate to extract 3 times, combine the extracts to recover acetic acid Ethyl ester extract. The extract was mixed with 100-200 mesh silica gel and ethyl acetate, added to silica gel column chromatography, eluted with petroleum ether / ethyl acetate (volume ratio 50:1), and the eluent was concentrated under reduced pressure to obtain a crude extract. For high-speed countercurrent separation. Mix n-hexane, ethyl acetate, ethanol, and water in a volume ratio of 1:3:1:2, shake and let stand to separate layers. Take the upper phase and fill the high-speed countercurrent chromatograph as the stationary phase, turn the main engine at a speed of 800rpm, and pump the lower phase at 2ml / min as the mobile phase. After the dynamic eq...

Embodiment 2

[0019] Crush the raw material of Eclipta chinensis, weigh 2kg, add 20L 60% methanol solution for ultrasonic extraction for 30 minutes each time, extract 3 times, extract the extract under reduced pressure to 1000ml, add an equal volume of water-saturated ethyl acetate to extract 3 times, combine the extracts to recover acetic acid Ethyl ester extract. The extract was mixed with 100-200 mesh silica gel and ethyl acetate, added to silica gel column chromatography, eluted with petroleum ether / ethyl acetate (volume ratio 40:1), and the eluent was concentrated under reduced pressure to obtain a crude extract. For high-speed countercurrent separation. Mix n-hexane, ethyl acetate, ethanol, and water in a volume ratio of 0.5:2:1:3, shake and let stand to separate. Take the upper phase and fill the high-speed countercurrent chromatograph as the stationary phase, turn the main engine at a speed of 800rpm, and pump the lower phase at 2ml / min as the mobile phase. After the dynamic equili...

Embodiment 3

[0021] The raw material of Eclipta chinensis is crushed, weighing 2kg, adding 17L 70% methanol solution for ultrasonic extraction for 30 minutes each time, extracting 3 times, the extract is concentrated under reduced pressure to 1000ml, adding an equal volume of water-saturated ethyl acetate to extract 3 times, and combining the extracts to recover acetic acid Ethyl ester extract. The extract was mixed with 100-200 mesh silica gel and ethyl acetate, added to silica gel column chromatography, eluted with petroleum ether / ethyl acetate (volume ratio 15:1), and the eluent was concentrated under reduced pressure to obtain a crude extract. For high-speed countercurrent separation. Mix n-hexane, ethyl acetate, ethanol, and water in a volume ratio of 0.5:1:1:2, shake and let stand to separate. Take the upper phase and fill the high-speed countercurrent chromatograph as the stationary phase, turn the main engine at a speed of 850rpm, and pump the lower phase at 3ml / min as the mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com