Preparation method for polyglutamic acid hydrogel and application of polyglutamic acid hydrogel in composite fertilizer

A polyglutamic acid, hydrogel technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of low utilization rate of fertilizer, waste, pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 300g of polyglutamic acid dry powder obtained by fermenting the fermented liquid prepared by Bacillus subtilis, precipitating with an organic solvent and then drying, add water to a volume of 3kg in a 5L beaker, stir and dissolve thoroughly, then add 5.5g of sodium hydrogen succinate epoxy , after stirring evenly, adjust the pH to 7.0 with sodium hydroxide or hydrochloric acid, stir and heat up to 60°C, react for 2 hours, then add 30g of polyethylene glycol glycidyl ether, stir well, adjust the pH to 5.0, heat up to 65°C, and keep warm Reaction, every 30 minutes, stirring for 5 minutes, reacting for 20 hours, to obtain a gel-like product; add the obtained product to soak in absolute alcohol for 12 hours to make it fully dehydrated. Put the dehydrated product into a vacuum drying oven at 55°C for drying, take it out and pulverize it to obtain the polyglutamic acid hydrogel superabsorbent resin.

Embodiment 2

[0016] The following is the application test of the compound fertilizer containing the polyglutamic acid water-absorbing resin prepared according to Example 2 on tomato planting. Wherein the fertilizer used in the control group is commercially available compound fertilizer (N-P 2 o 5 -K 2 O 25-15-8), the test group made compound fertilizer by adding polyglutamic acid superabsorbent resin to the fertilizer of the same brand.

[0017] The compound fertilizer applied in the test group is to add 1% polyglutamic acid water-absorbing resin, the compound fertilizer applied in the test group two is polyglutamic acid water-absorbing resin with an addition of 0.5%, and the compound fertilizer applied in the test group three is polyglutamic acid The amount of water-absorbent resin added is 0.1%. The compound fertilizer polyglutamic acid water-absorbing resin added in the four groups of experiments was 0.05%.

[0018]

[0019] control group test group Test group two ...

Embodiment 3

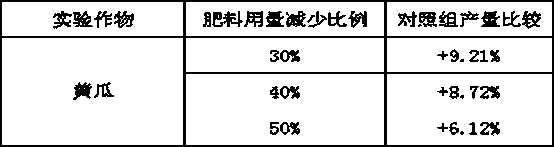

[0022] The following experiment is the application of polyglutamic acid water-absorbing resin in vegetable fertilizer saving and yield increasing. Wherein the fertilizer used in the control group is commercially available compound fertilizer (N-P 2 o 5 -K 2 O 25-15-8), the experimental group was made by adding polyglutamic acid superabsorbent resin to the fertilizer of the same brand. The following data are the average of the results obtained by repeating more than three times.

[0023]

[0024]

[0025] It can be seen from the above table that the crop yield still increases even though the amount of fertilizer application is reduced, which shows that the polyglutamic acid water-absorbing resin improves the utilization rate of fertilizer, can significantly reduce the amount of fertilizer, and save costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com